泵轮加工工艺设计

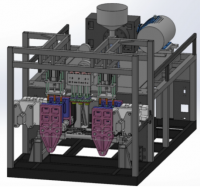

摘要:在实际生产过程中,很多行业中一些形状较复杂产品特别是加工批量较大的零件,利用通用夹具难以装夹。即便勉强可以装夹但零件的装夹和加工难度也同时提高,精度难以保证,工人劳动强度提高,所耗工时增加,成本提高,加工生产效率低。

为了便于零件的装夹和加工同时保证加工质量,降低工人劳动强度,降低成本,提高生产加工效率需要使用专用夹具。

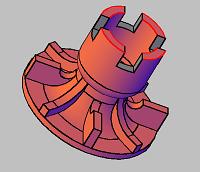

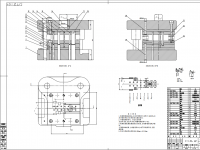

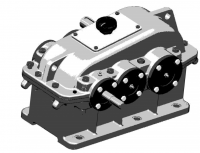

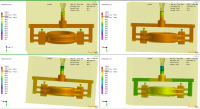

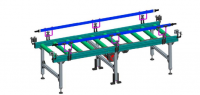

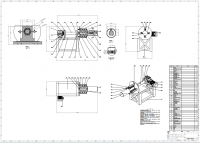

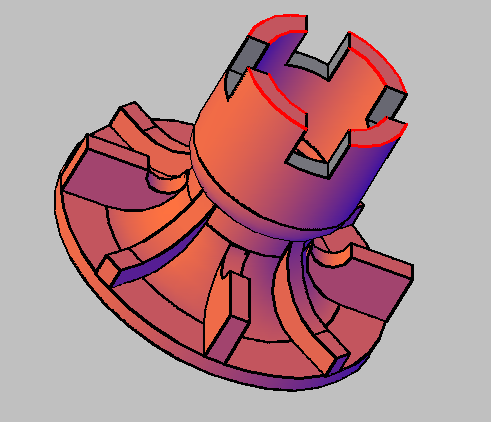

本课题主要是对水泵叶轮的机械加工工艺规程的设计及工艺装备的设计(年产量为10000件),为企业解决实际的问题。针对该水泵叶轮的尺寸特殊性、加工工序和机床的良好使用,则需设计一套专用夹具,从而确保车削水泵叶轮Ф80底面和铣削水泵叶轮两条相互垂直的槽的精度,提高生产效率,保证零件的产量。

本课题的设计综合运用了我们所学的机械制图、机械设计基础、机床概论、机械制造工艺学、机床夹具设计等专业理论知识。

关键词:水泵叶轮、工艺、夹具。

Abstract: In the actual production process, many industries in the shape of some of the more complex products, particularly large quantities of spare parts processing, use common fixture to fixture. But even if barely fixture parts of the fixture and also improve the processing difficulty, it is difficult to guarantee the accuracy, increased labor intensity of workers, increase working hours by consumption, increased cost, low efficiency of the production process.

In order to facilitate the processing and parts of the fixture at the same time ensure that the processing quality, reduce labor intensity of workers, reduce costs and improve efficiency of production and processing need to use special fixture.

The main topic of the pump impeller machining process planning the design and the design of equipment (annual production of up to 10,000), for enterprises to solve practical problems. Against the size of the pump impeller particularity, processing and the good use of machine tools required to design a special fixture, so as to ensure that turning pump impeller Ф80 milling pump impeller and the bottom two mutually perpendicular to the trough of accuracy, increase productivity and ensure Part of the output.

The design of the integrated use of the topics that we have learned mechanical drawing, mechanical design basis, machine Studies, machinery manufacturing technology, machine tool fixture design professionals such as theoretical knowledge.

Key words: pump impeller, process, fixture.

目 录

第一章绪论.................................................................................................................................................1

1.1机床技术各方面的发展.............................................................................................................1

1.2铣床加工特点................................................................ ....................... ....................... .......... 2

1.3铣床加工的顺序............................................................ ............ .......... ........ .......... ........ ......3

第二章 零件的分析................................................................................................................4

2.1零件的作用......................................................................................................................................3

2.2 零件的工艺分析.........................................................................................................................3

2.2.1零件的结构、形状、技术要求........................................................................... ...3

2.2.2零件的加工方案选择............................................................................ ...... .............. 5

2.2.3确定切削用量及基本工时............................................................................ .............. ........6

第三章 工艺规程的分析........................................................................................................................ 8

3.1生产纲领和生产类型的确定..................................................................................................8

3.2确定毛坯制造形式......................................................................................................9

3.3毛坯尺寸与机械加工工艺尺寸确定....................................................................10

3.3.1加工余量的确定...................................................................................11

3.3.2工序尺寸及其公差的确定........................................................................................12

3.4基准的选择.........................................................................................12

3.4.1基准的概念...................................................................................................12

3.4.2定位基准的选择原则....................................................................................................13

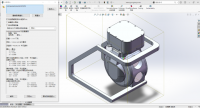

3.5选择加工设备及刀具、夹具、量具..................................................................................................14

3.5.1 选择加工设备与工艺设备................................................................................................ 14

3.5.2 选择夹具.............................................................................................................................14

3.5.3 选择量具..............................................................................................................................16

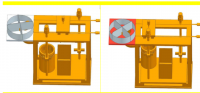

第四章铣床夹具的设计.................... ................ ................ .......................... ........................................16

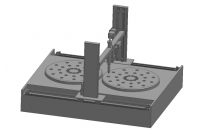

4.1卧式铣床夹具的设计......................................................................................................................16

4.1.1问题的提出.............................................................................................................................17

4.1.2定位基准的选择........................................................................................... ... ................ . 17

4.1.3夹具的结构设计.............................................................................................................. . ... 18

4.1.4定位元件的选择及要求................................................................................................ ... . .19

4.1.5夹紧元件的选择............................................................................................................ ... 19

4.1.6夹具体的设计....................................................................................................... .. .. .... ... 19

4.1.7夹紧方案的设计............................................................................................................. ... 19

4.2夹具设计及操作的简单说明...................................................................................................................20

第五章总结...............................................................................................................................................21

参考文献.....................................................................................................................................................22

附录...............................................................................................................................................23

附件1:毕业设计(论文)指导记录表……......………..........................................................................23

附件2:用人单位毕业设计鉴定表……......………..............................................................................24

参考文献

[1]没康焘,机械制图,上海,上海交通大学出版社,2000

[2]陈立德 李晓辉,机械制造技术(第二版),上海,交通大学出版社,2004

[3]赵家齐,机械制造工艺学课程设计指导用书(第二版),北京,机械工业出版社,1994

[4]艾兴 肖诗纲,切削用量简明手册,北京,机械工业出版社,1994

[5]哈尔滨工业大学,上海工业大学主编《机床夹具设计》,上海,上海科学技术出版社,1983

[6]东北重型机械学院,洛阳工学院,第一汽车制造长职工大学编,《机床夹具手册》,上海,上海科学技术出版社,1990

[7]孟宪栋 刘彤安 机床夹具图册,机械工业出版社,200

http://www.bysj1.com/html/5839.html

http://www.bysj1.com/html/6302.html