基于solidworks微型光电云台结构设计与分析

摘要

微型光电平台是一种用于执行光电仪器设备动作功能的承载设备。随着光电仪器设备在车载、机载、维修救灾以及机器人等领域应用场合的扩大,对微型光电平台的性能提出了更高的要求。随着工业高精度要求,轻量化,结构更优异的微型光电云台需求越来越强烈。

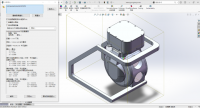

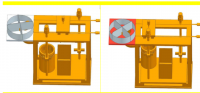

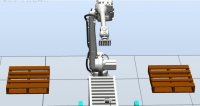

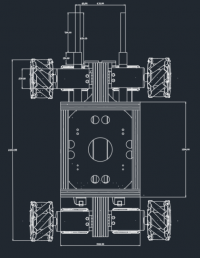

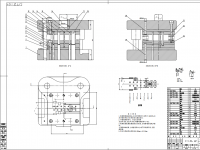

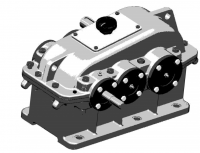

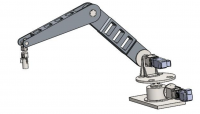

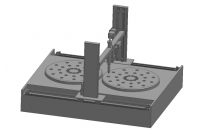

首先,在调研现有微型光电平台同类产品的基础上,选择了三种主体结构设计方案进行对比对象,在对比比较三种主体结构的基础上,选择了“法兰-旋转圆盘-外围框架”的上下旋转、“方形圆盘-外围框架”的左右旋转为最佳结构设计方案进行微型光电平台模型的设计与装配。

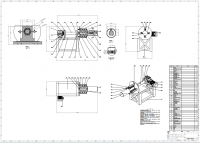

其次,对已建立的微型光电平台模型进行整体结构分解的详解,具体说明各机构的作用与设计需求;对微型光电平台主体结构设计进行拆分详解,具体说明重要部件间相互的联系,与其各自的运动方式。

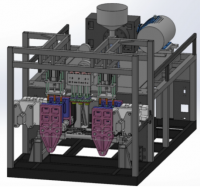

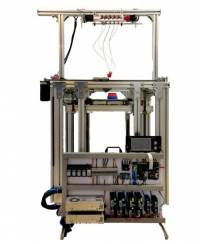

然后,根据微型光电平台主体结构和各重要组件的联系与要求,进行3D打印,进一步确定微型光电平台结构优化后,其“法兰-旋转圆盘-外围框架”的上下旋转、“方形圆盘-外围框架”的左右旋转结构存在的优越性。同时,也对加工工艺提出了一定的要求。

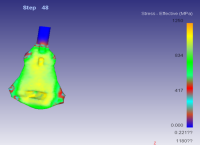

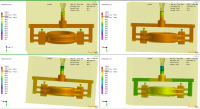

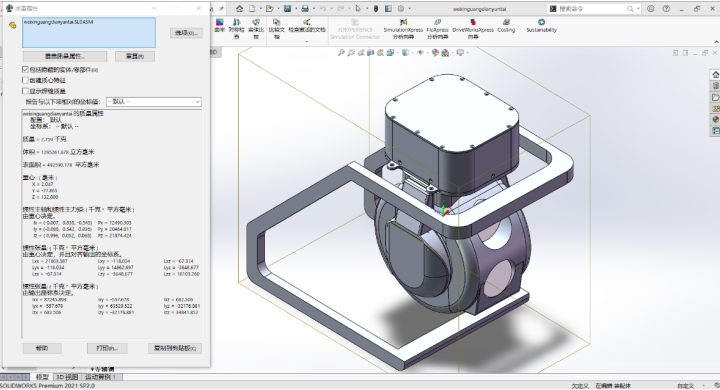

最后,利用所建立的整机几何模型,选取微型光电平台重要组件“法兰-旋转圆盘-外围框架”的上下旋转、“方形圆盘-外围框架”的左右旋转结构、顶部传输组件,通过SOLIDWORKS应用中自带的插件SOLIDWORKS Simulation建立了整体结构的有限元分析模型,通过静应力分析微型光电平台在施加100N冲击力,并将材料设置为铝合金1060情况下的屈服应力与变形总位移,评估了微型光电平台中重要结构的力学性能。

本文提出的微型光电平台光结构能够在进行简单的抗冲击性能的条件下进行结构的设计与优化。本文针对微型光电平台的轻型、结构灵活的设计需求上,采用了“先主体结构,后细节优化”的设计方法,完成了体积小、轻量化、结构灵活的微型光电平台的设计。

关键词:微型光电云台、结构优化、轻量化、3D打印、有限元分析

ABSTRACT

The miniature optoelectronic platform is a kind of load-bearing equipment used to perform the action function of optoelectronic instruments and equipment. With the expansion of applications of optoelectronic instruments and equipment in the fields of vehicle-mounted, airborne, maintenance and disaster relief, as well as robotics, the performance of micro-optoelectronic platforms has put forward higher requirements. With the industrial high-precision requirements, lightweight, structurally superior micro-optoelectronic head demand is increasingly strong.

First of all, in the research of existing micro photoelectric platform based on similar products, selected three main structure design program for comparison of the object, in the comparison of the three main structure based on the selection of "flange - rotating disk - peripheral frame" of the pitch rotation, "square disk - peripheral frame" of the left and right rotation as the best. On the basis of comparing the three main structures, the "flange-rotating disk-peripheral frame" of pitch rotation and the "square disk-peripheral frame" of left-right rotation are selected as the best structural design scheme for the design and assembly of the miniature photoelectric platform model.

Secondly, the established micro-optoelectronic platform model is decomposed in detail to specify the role of each organization and design requirements; the main structure of the micro-optoelectronic platform is decomposed in detail to specify the linkage between the important parts and their respective movement modes.

Then, according to the main structure of the micro-optoelectronic platform and the connection and requirements of the important components, 3D printing is carried out to further determine the optimized structure of the micro-optoelectronic platform, its "flange-rotating disk-peripheral frame" of the pitch rotation, "square disk-peripheral frame" of the left and right rotation structure exists. The superiority of the "square disk-peripheral frame" and "square disk-peripheral frame" left-right rotation structure exists. At the same time, it also puts forward certain requirements for the machining process.

Finally, using the established geometric model of the whole machine, the important components of the miniature optoelectronic platform "flange-rotating disk-peripheral frame" pitch rotation, "square disk-peripheral frame" left and right rotating structure, and the top transmission component are selected and processed through the SOLIDWORKS application. SOLIDWORKS Simulation, a plug-in that comes with the SOLIDWORKS application, establishes a finite element analysis model of the overall structure, and evaluates the mechanical properties of the important structures in the miniature photovoltaic platform by analyzing the yield stress and total deformation displacement of the miniature photovoltaic platform through static stress analysis in the event of applying an impact force of 100N and setting the material as aluminum alloy 3003.

The optical structure of the micro optoelectronic platform proposed in this paper can be designed and optimized under the condition of simple impact resistance. In this paper, for the lightweight, flexible structure of the miniature photoelectric platform design needs, using the "first main structure, after the details of the optimization" design method, to complete the small size, lightweight, flexible structure of the miniature photoelectric platform design.

Keywords: miniature optoelectronic head, structure optimization, lightweight, 3D printing, finite element analysis

目录

摘要

ABSTRACT

第一章 绪论 1

1.1 研究背景 1

1.2 研究目的 2

1.3 技术路线 3

1.4 主要研究内容 3

第二章 微型光电云台整体结构设计 4

2.1 微型光电云台的总方案设计 4

2.2 微型光电云台整体结构分解 7

2.3 微型光电云台主体结构设计 11

2.4 小结 12

第三章 基于3D打印对微型光电云台的研究 13

3.1 微型光电云台结构分析 13

3.2 3D打印微型光电云台 13

3.3 3D打印件结构分析 19

3.4 小结 23

第四章 微型光带云台的性能分析 24

4.1 微型光电云台的仿真分析 24

4.2 微型光电云台的性能分析 30

4.3 小结 34

第五章 总结与展望 36

5.1 总结 36

5.2 展望 36

致谢 38

参考文献 40

参考文献

[1] 富晓杰. 高精度伺服云台的机械结构与控制系统研究[D]. 浙江:浙江大学机械电子工程, 2014.

[2] 宋宇航, 李红双, 娄照坤. 一种机器人云台的设计与试验研究[J]. 机械设计, 2022,39(S2): 14-18.

[3] 刘瑞, 蒋蓁, 雷小光. 小型机载云台结构设计和分析[J]. 机电工程, 2010,27(2): 5-7.

[5] 杨奇彪, 王靖雄, 唐德红. 基于人机工程的手持云台设计研究[Z]. 2021151-155.

[6] 李硕. 辐射环境专用伺服云台设计及关键技术[J]. 机床与液压, 2020,48(22): 113-116, 166.

[7] 喻伯牙, 易华辉, 侯羽生, 等. 适用于多旋翼无人机的两轴云台结构设计[J]. 机电工程技术, 2021,50(9): 61-65, 83.

[8] 熊智慧. 高速电视摄像在靶场测量系统中的应用[J]. 中国测试, 2012,38(1): 82-84, 89.

[9] 张素香, 张宇轩. 用于车载光电系统的自锁式云台结构设计[J]. 中原工学院学报, 2021,32(4): 34-37, 82.

[12] 王鹏飞. 二自由度云台视觉伺服控制系统的设计与实现[D]. 江苏:南京理工大学机械工程, 2019.

[13] 陈彤阳, 王向军. 面向小型无人机的两轴稳像云台控制系统[J]. 仪表技术与传感器, 2021(8): 63-68.

[16] 石磊, 许永森, 田大鹏, 等. 钢丝绳传动航空光电稳定平台设计[J]. 光学精密工程, 2020,28(6): 1245-1253.

[17] 张卫国, 侯军占, 段红建, 等. 精密柔性传动技术在光电系统中的应用研究[J]. 应用光学, 2017,38(3): 341-347.