基于PLC控制的多材质工件分拣设备

摘要:PLC控制是目前工业上最常用的自动化控制方法,由于其控制方便,能够承受恶劣的环境,因此,在工业上优于单片机的控制。PLC将传统的继电器控制技术、计算机技术和通信技术融为一体,专门为工业控制而设计,具有功能强、通用灵活、可靠性高、环境适应性强、编程简单、使用方便以及体积小、重量轻、功耗低等一系列优点,因此在工业上的应用越来越广泛。

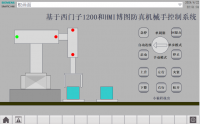

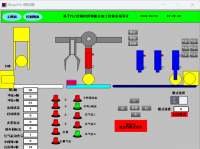

本文主要讲述PLC在材料分拣系统中的应用,利用可编程控制器( PLC) ,设计成本低、效率高的材料自动分拣装置。以PLC 为主控制器,结合气动装置、传感技术、位置控制等技术,现场控制产品的自动分拣。 系统具有自动化程度高、运行稳定、精度高、易控制的特点,可根据不同对象,稍加修改本系统即可实现要求。

关键词: 可编程控制器;分拣装置;控制系统;传感器

Based on PLC control material artifacts sorting equipment

Abstract: PLC control is the most commonly used industrial automation control method, because of its convenient control to withstand an adverse environment, it is better than MCU control in the industrial. PLC traditional relay control technology, computer and communication technologies are integrated specifically for industrial control and design, have strong function, common flexible, high reliability and environmental adaptability, and programming simple, easy to use and small size, light weight, a series of low-power advantages in industrial applications become more extensive.

This paper focuses on the PLC in the canned beverage production, The design of an automatic sorting device with low cost and high efficiency is presented in the paper, which regards programmable logic controller ( PLC) as the master controller and combines pneumatic device, sensing technology, position control and other technology to implement automatic selecting of the products live. The device is characteristic of high automation, steady running, high precision and easy control, which can fulfill the requirement according to different situations with little modifications.

Key words:programmable logic controller,sorting device,control system,sensors

目录

第1章 引言

1.1课题来源及研究意义······································3

1.2本文的主要研究内容······································3

第2章 材料分拣装置的结构设计

2.1材料分拣装置工作过程概述································5

(1)系统的技术指标

第3章 控制系统的硬件设计

3.1 PLC可编程器··············································6

3.2控制系统设计··············································8

3.2.1传感器选用··············································9

(1)电感式

(2)电容式

(3)光电开关

(4)磁性开关

3.2.2变频器控制电路设计······································12

(1)变频器选用

(2)变频器主电路设计

(3)变频器控制电路设计

(4)变频器参数设置

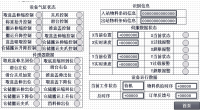

3.2.3 I/O分配表与元器件····································14

3.2.4硬件接线图 ·············································17

3.2.5 气动元件的设计···········································18

(1)气缸

(2)电磁阀

第4章 控制系统的软件设计

4.1 控制要求················································19

4.2 流程图设计··············································20

4.3 梯形图设计··············································22

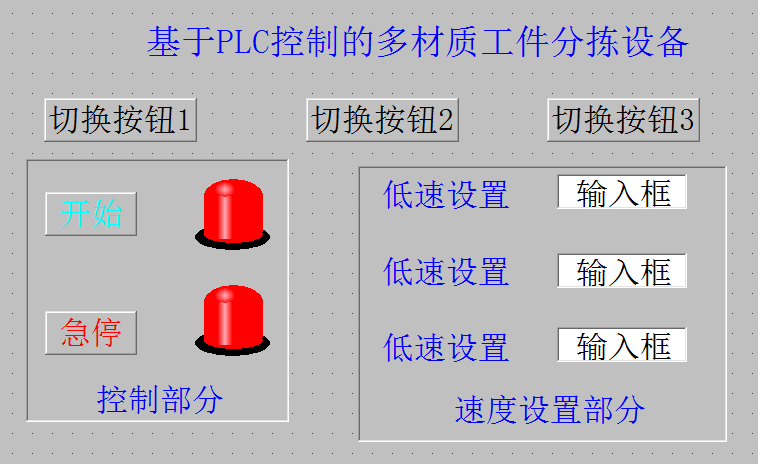

4.4 触摸屏设计··············································26

(1)开机登录画面

(2)控制画面

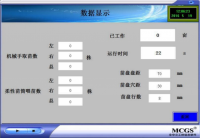

(3)数据监控画面

(4)报警画面

(5)调试画面

第5章 控制系统的调试

5.1 硬件调试················································31

5.2 PLC程序调试·············································31

5.3 整体调试················································31

结论

致谢

参考文献

参考文献

1.PLC应用技术/郭琼主编—北京:机械工业出版社,2009,6

2.电气与可编程序控制器技术/汤以范主编—机械工业出版社,2004

3.PLC控制系统设计与应用/周柏青,李方园主编—北京:中国电力出版社,2015,8

4.工控组态技术及应用—MCGS/李红萍主编—西安电子科技大学出版社,2013,1

5.MCGS嵌入版说明书/昆仑通态

6.组态控制技术/袁秀英主编—电子工业出版社,2007

7.交流调速系统及应用/黄麟主编-大连理工大学出版社2009,8

http://www.bysj1.com/html/6486.html

http://www.bysj1.com/html/6469.html

http://www.bysj1.com/html/6483.html