鸡饲料工厂粉料自动配料装置的设计(毕业论文致谢怎么写?)

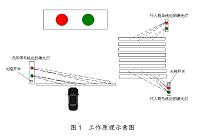

摘要:现代生活中,鸡肉已经成为人们肉类需求中重要的一种肉类,鸡肉不仅营养丰富,并且味道鲜美,并且易于烹饪,成为了大众口味。并且,鸡还能生蛋,鸡蛋也是人们必不可缺的一种食物。在市场对鸡的需要量一天天增多的同时,鸡的品质也变得异常重要。好的鸡鸡肉品质过硬,产的蛋也很好。这之中,鸡饲料就成为了比较重要的东西。因为在养鸡场,鸡一般都是吃鸡饲料长大的,毕竟养鸡场鸡的量大,种类多。不能像普通农村家庭散养几只鸡,可以任由他们吃一些平常的食物。所以必须喂给他们鸡饲料。什么样的鸡饲料才能让鸡长得又快又肥肉质又好呢。鸡饲料的配方重要之处就在这时候体现了。在鸡饲料生产过程中,需要将多种原料按一定配方比例调配,然后进行加工,鸡饲料质量的好坏与配方准确度有相当大的关系。配方好了,鸡饲料质量就上去了。这样就能使得鸡的品质也上去。人工按比例配方饲料难免会出现偏差。但是现代社会的优势是什么,是科技。所以为了提高产品质量,我们要设计一个自动配料装置:由一辆用电机驱动的小车,在配饲料的原料区多个原料中按要求自动行走,完成人工取料的步骤,取完后行走到下一点,直至结束,回到原点。

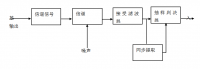

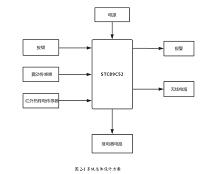

此课题采用PLC为主控制器,结合触摸屏,使小车运动可根据操作者设定在6个工作点(原料点)运动。此课题综合了电机学、工厂电气控制设备、PLC、组态技术等多门课程的知识点。是一篇比较综合性的毕业设计。

关键词:PLC;触摸屏;自动配料

Design of automatic feeding device for feed mill

Abstract:Scattered chicken chicken chicken on a demand for meat of modern life, the chicken has become a kind of meat, chicken is not only nutritious and delicious and easy to cook, to become the public taste. And, the chicken can lay an egg, the egg is one of the indispensable food. In the market needs a day increased at the same time, chicken quality also becomes very important. Good quality excellent, the production of eggs is also very good. This chicken feed become more important things. Because in the chicken farm, chicken is chicken feed grew up, after all, the chicken farm chicken, many kinds. Not like an ordinary rural families raise a few chickens. So what is the advantage of good accuracy, allocate and let them eat normal food. So you must feed them chicken feed. What kind of chicken feed to keep the chickens grow fast and fat meat. Chicken feed formula is important at this time reflected in chicken feed production process, the various raw materials according to a certain proportion, and then processed chicken feed quality is good or bad and formula is quite large. The recipe, chicken feed quality went up. So that we can make chicken quality also up. Artificial according to the proportion of feed formula will

inevitably appear deviation. But modern society, science and technology. In order to improve the product quality, we want Design an automatic dosing device: by a car driven by a motor car, in feed raw material area of raw materials according to the requirements of the automatic walking, artificial reclaiming steps have been completed, take after walking to the next point until the end. Back to the origin.

This subject adopts PLC as main controller, in combination with a touch screen, make the car movement can be set in six working point (materials) motion according to the operator. This paper integrated motor learning, the factory electrical control equipment, PLC and configuration technology, multi course knowledge. Is a comprehensive comparison of graduation design.

Key words: PLC; touch screen; automatic batching

目 录

一、引言 .............................................................................................4

1.1课题来源及研究意义................................................................4

1.2鸡饲料加工现状以及缺点..........................................................4

1.2.1鸡饲料加工现状................................................................4

1.2.2鸡饲料加工现状的缺点.......................................................4

1.3本课题的主要设计方案.............................................................4

1.4本课题的主要研究内容.............................................................5

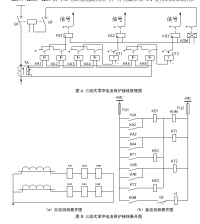

1.5两种控制方法.........................................................................5

1.5.1 PLC控制.........................................................................5

1.5.2接触器-继电器控制 ..........................................................7

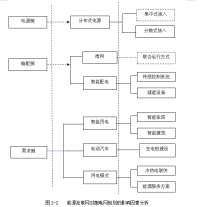

二、采用PLC控制的鸡饲料自动配料装置总体结构.....................................8

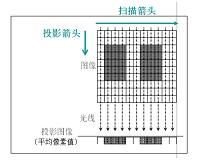

2.1鸡饲料固定比例配方概述..........................................................8

2.2鸡饲料自动配料装置结构概述....................................................9

2.3 PLC简介...............................................................................9

2.3.1 PLC的产生与发展.............................................................9

2.3.2 PLC的主要产品...............................................................10

2.3.3 PLC的基本结构...............................................................11

三、自动配料装置控制系统硬件设计.......................................................12

3.1自动配料控制系统硬件设计......................................................12

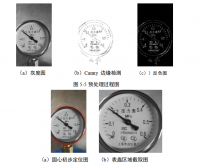

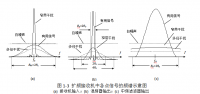

3.2接近开关设计........................................................................12

3.3电磁阀.................................................................................13

3.4取料小车电机........................................................................13

3.5触摸屏设计...........................................................................14

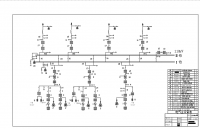

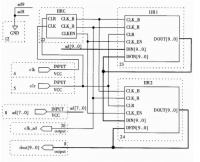

3.6 PLC设计..............................................................................15

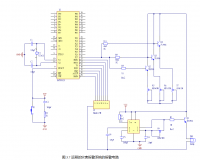

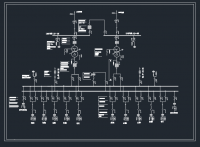

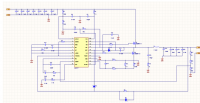

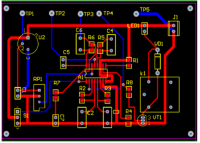

3.7装置外部接线设计..................................................................16

四、自动配料装置控制系统软件设计....................................................17

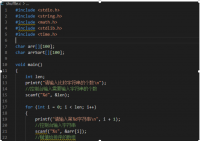

4.1 PLC控制系统软件设计............................................................17

4.1.1 PLC流程图和I/O分配表...................................................18

4.1.2主程序介绍.....................................................................19

4.2触摸屏软件设计.....................................................................22

4.2.1编辑软件TouchWin介绍........................................................22

4.2.2人机界面内部对象............................................................24

4.3TouchWin配方及运行界面展示...................................................24

五、全文结论.......................................................................................27

六、参考文献.......................................................................................28

七、致谢........................................................................................29

八、附录........................................................................................30

附录一 PLC梯形图主程序............................................................31

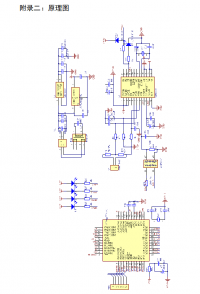

附录二 人机界面设置.................................................................36

附录三 元器件清单....................................................................38

附录四 寄存器对照表.................................................................38

附录五 运行界面变量定义表........................................................39

参考文献

1.工厂电气控制设备/张晓娟主编.-北京:电子工业出版社;北京交通大学出版社,2012.1

2.PLC应用技术/郭琼主编.-北京:机械工业出版社,2009.6 (2013.7重印)

3.高等学校毕业设计(论文)指导教程/电气工程类专业华莹,董婷主编--北京:中国水利水电出版社,2015.5

4.小型综合自动化系统集成/奚茂龙,陆荣主编.-西安:西安电子科技大学出版社,2014.9

5..电子电路原理分析与仿真/许自图编著-北京:电子工业出版社,2006.10

6.PLC编程实用技术/宋伯生主编.-北京:机械工业出版社,2007

7.电气控制与PLC应用技术/田效伍主编.-北京:机械工业出版社,2006

8.可编程序控制器基础及应用/廖常初主编. .-北京.:机械工业出版社.2007.6

9.电气控制与PLC应用/余雷声主编. -北京.:机械工业出版社. 1996.10

10.工厂电气控制设备/赵明.主编.-北京:机械工业出版社,1998

11.工程生产自动化/王成主编.-北京:科学出版社,2003

12.自动控制原理与系统/孔凡才编著-3版-北京:机械工业出版社,2007.2

13.自动检测与转换技术/梁森个,黄抗美编著-3版-北京:机械工业出版社,2007.5

14.信捷PLC通讯手册

15.信捷PLC课程讲义

16.信捷PLC特殊指令说明书