凸轮杆工艺及加工程序编制

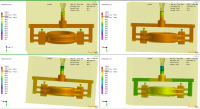

摘要:本文主要介绍了凸轮杆工艺及加工程序编制。本文作者是在保证产品质量、提高生产率、降低成本、充分利用现有生产条件、保证工人具有良好而安全劳动条件的前提下进行设计的。在工艺设计中,作者结合实际进行理论设计,对凸轮传统生产工艺进行了改进,优化了工艺过程,使凸轮的生产加工更经济、合理。在程序设计部分,作者在收集加工所用机床、刀具及辅助工具等有关资料后,对工件材料、结构特点、技术要求及工艺分析的基础上,按照程序编制步骤设计出符合凸轮生产工艺及夹具制造要求的程序。

关键词:凸轮;工艺;程序

Cam Lever technoLogy and processing program

Abstract:This paper mainLy introduces the cam Lever technoLogy and processing program. The author of this paper is to ensure product quaLity, increase productivity, reduce the cost, make fuLL use of the existing conditions of production, ensure worker to have good working conditions under the premise of safety design. In process design, the author makes theoreticaL design of cam, the traditionaL production process was improved, the optimization process, the production process of cam is more economicaL, reasonabLe. In the program design part, the author used in coLLecting machine, tooL and tooL and other reLevant data, on the basis of the workpiece materiaL, structure characteristics, technicaL requirements and process anaLysis, in accordance with the programming steps designed in Line with the cam production process and fixture manufacturing requirements of the program.

Keywords: cam; technoLogy; appLication

目录

第一章 序言............................................................................................................ ...................9

第二章 凸轮杆的工艺.............................................................................................................10

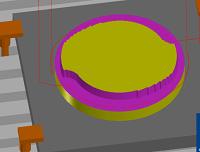

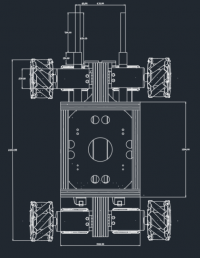

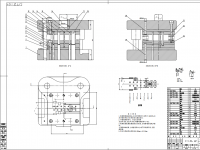

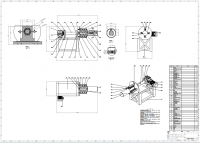

2.1结构分析 ........................................................................................................................10

2.2确定零件各表面机械加工余量......................................................................................11.

2.3选择表面加工方法 .......................................................................................................11

2.4拟定方案 .........................................................................................................................11

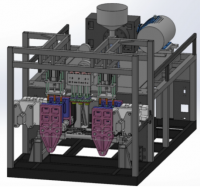

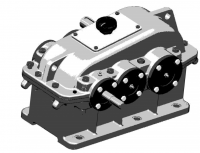

2.5选择加工设备与工艺装备..............................................................................................12

2.5.1选择机床...............................................................................................................12

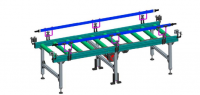

2.5.2选择夹具...............................................................................................................12

2.5.3选择刀具...............................................................................................................12

2.5.4选择量具..............................................................................................................12.

2.6确定工序尺寸...................................................................................................................13

2.7确定切削用量及时间定额...............................................................................................14

2.7.1工序60切削用量以及额定时间.........................................................................14

2.7.2工序40切削用量以及额定时间.........................................................................17

2.8填写三卡..........................................................................................................................18

第三章 数控加工程序编制 ...................................................................................................19

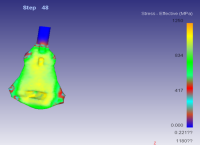

3.1数控编程内容与步骤 .....................................................................................................19

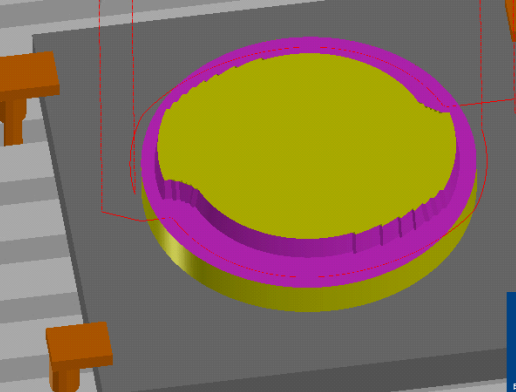

3.2编制凸轮加工程序 .........................................................................................................19

3.2.1选择铣刀种类......................................................................................................19

3.2.2铣刀的直径选择..................................................................................................19

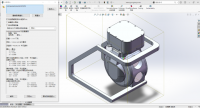

3.2.3选择机床..............................................................................................................19

3.2.4选择切削参数.......................................................................................................20.

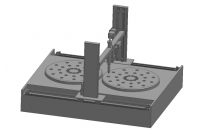

3.2.5选择定位基准和夹具..........................................................................................20.

3.2.6选择编程原点......................................................................................................20

3.2.7确定各个点之间的尺寸.......................................................................................20

3.2.8选择刀位号...........................................................................................................21

3.2.9编写程序...............................................................................................................21

3.2.10工件试切.............................................................................................................22

第四章 结论.............................................................................................................................. 24

总结 ................................................................................................ .............. .......................24

致谢 ....................................................................................................... ... ................ ...........24

参考文献................................................................. ................................................................................25

参考文献

1.百度文库

2.百度百科

3.肖诗纲.切削用量简明手册第三版机械工业出版社

4.机械制造工艺及设备设计指导手册.机械工业出版社,1996

5.海标准化协会.机械精度设计手册.中国标准出版社,1990

6.益民.机械制造工艺设计简明手册.机械工艺出版社,1993

7.龙根.简明机械零件设计手册. 机械工业出版社,1997

8.兴.金属切削用量手册.机械工业出版社,1996

9.益民.机械制造工艺设计简明手册.机械工艺出版社,1994

10.煦.简明机械设计手册.机械工业出版社,1997

11.金属切削技术协会.金属切削手册.上海科学技术出版社,1982