基于S7-200的液位控制系统设计

摘要:现代工业自动化的三大支柱——可编程逻辑控制器(PLC)凭靠着它的可靠性,灵活性,已在工业控制领域得到了迅速的发展。PLC主要是由微电子技术和自动控制技术相组合的产品,并且被计算机技术和通信技术所影响。近年来,我国工业自动化水平的逐步提高,在许多行业里PLC得到了越来越广泛的应用。S7-200系列PLC作为西门子公司的简单控制产品,具有结构紧凑,扩展能力强,性价比高的特点,在许多行业中得到广泛运用。

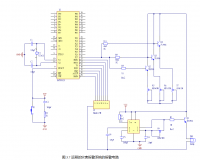

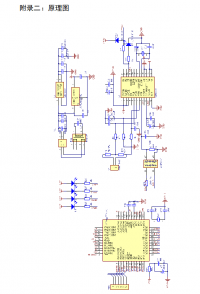

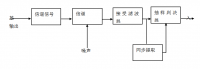

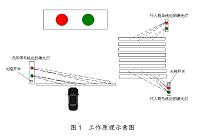

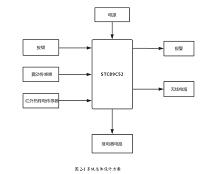

在本次设计的课题中,就以S7-200作为控制器,设计一个能够稳定运行、可靠、安全又经济的液位控制系统。控制的核心以S7-200系列的CPU224为主,以电磁阀、液位开关、水泵、变频器等为辅构成了单容水箱的液位控制系统,同时对整个液位控制系统进行了硬件和软件设计。

在设计过程中,首先就是进行硬件的选择、设计。其次,针对S7-200PLC的进行模块化编程,实现液位的自动控制,上下限的位置设置,从而达到液位控制系统的技术要求。

关键词:S7-200;变频器;液位控制

Abstract:The three pillars of modern industrial automation -- a programmable logic controller (PLC)based on its reliability, flexibility, has obtained the rapid development in the field of industrial control. PLC is mainly composed of micro electronic technology and automatic control technology of combination of products, and be influenced by computer technology and communication technology. In recent years, and gradually increase the level of industrial automation in China, PLC has been more and more widely used in many industries. Simple-control products as Siemens company's S7-200 series PLC, has the advantages of compact structure, high expansible, high cost performance, has been widely used in many industries.

In this design, it uses S7-200 as the controller, the design of a stable, reliable, safe and economic operation of the liquid level control system. The control core with S7-200 seriesCPU224, the electromagnetic valve, liquid level switch, water pump, frequency converter as a single tank liquid level control system, but also for the liquid level control system for the hardware and software design.

In the design process, first of all is the hardware selection, design. Secondly, according to theS7-200PLC modular programming, to achieve automatic control of the upper and lower level,position setting, in order to meet the requirements of the liquid level control system-technology.

Keywords: S7-200; frequency converter; liquid level control

目录

摘要·····························································Ⅰ

Abstract·························································Ⅱ

第一章 绪论················································· 1

1.1可编程逻辑控制器(PLC)概论································· 1

1.2液位控制系统的背景及意义······························ 1

1.3液位控制系统的国内外研究现状································ 2

1.4液位控制系统的研究内容·································· 2

二、第二章 液位控制系统的总体设·······························3

2.1液位控制系统的整体设计思路···························· 3

2.2液位控制系统的组成··································· 3

第三章 液位控制系统的机械系统设计··························8

3.1水泵功率计算与选用··································8

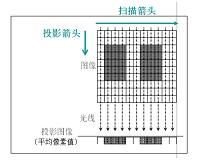

3.2 水箱组的设计············································9

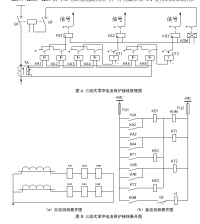

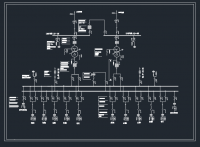

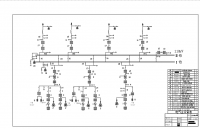

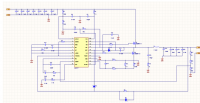

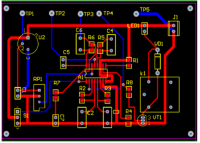

第四章 液位控制系统的电气控制系统的设计····················13

4.1 液位控制系统设计思路·····························13

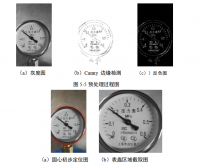

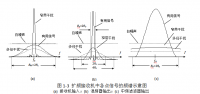

4.2 各种传感器的选型和安装方式······························15

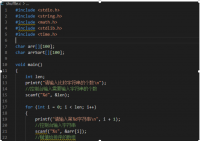

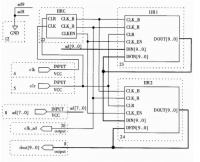

4.3 PLC控制程序设计···········································17

第五章 毕业小结···············································27

致谢····························································30

参考文献·························································30

参考文献

[1] 宋建成. PLC控制和应用. 科学出版社. 2002年.

[2] 吴中俊,黄永红²可编程序控制器原理及应用²北京:机械工业出版社,2003

[4] 晁阳,胡军,熊伟.可编程控制器原理应用与实例解析.北京.清华大学出版社.2007

[6] 王永华. 现代电气及可编程控制技术.北京航空航天大学出版社.第一版.2002年9月.

[7] 吴建强,姜三勇²可编程控制器原理及应用²哈尔滨工业大学出版社,2000.

http://www.bysj1.com/ http://www.bysj1.com/html/1715.html http://www.bysj1.com/html/3965.html