基于PLC恒压供水系统设计

摘要:

随着社会主义市场经济的发展,人们急迫的需要用水质量和可靠性要求不断提高的供水系统,再加上目前能源紧缺,利用先进的自动化技术,控制技术和通信技术,设计出高性能,高可靠性,高节能性的能适应供水系统的不同区域已经成为一种必然趋势

本文分析了变频恒压供水系统的结构和原理的组成,并提出不同的控制方案,通过研究和比较,本文采用变频器和PLC恒压供水和数据传输,然后使用数字PID智能调节方式控制系统压力的设计。最后,该系统的硬件和软件设计进行了详细说明。在本文中,通过上位机组态软件,设计和实现数据传输及具体的关于整体设计的系统软件和使用,并采取系统的保护措施以提高系统可靠性方面进行了描述。

关键词:变频调速;恒压供水;PLC;组态王;上位机

PLC constant pressure water supply system

Abstract:With the development of socialist market economy,the supply system of people urgently need water quality and reliability requirements continue to increase,coupled with the current energy shortage,use of advanced technique of automation,control technology and communication technology,the design of high performance,high reliability,high energy saving can adapt to different regional water supply system has already become a kind of an inevitable trend

This paper analyses the structure and principle of variable frequency constant pressure water supply system,and puts forward the different control schemes,through research and comparison,this paper adopts and PLC constant pressure water supply and data transmission,the design and use of intelligent digital PID regulator control system pressure.Finally,the design of hardware and software of the system are described in detail.In this paper,through the remote network monitoring system design and implementation of MCGS,data transmission and spec the overall design of the system software and use,and take measures to protect the system to improve the reliability of the system are described.

In this paper,the constant pressure water supply system has been many practical living water supply control system,and made use of the evaluation of stable and reliable and good energy saving effect.The system has been proved to have high reliability and real-time,greatly improving the quality of the water supply,and save manpower,has obvious economic and social benefit.

Key words: frequency control of motor speed; Constant pressure water supply; PLC; Upper machine

目 录

摘要 .........................................................................................................................1

第一章 绪论.........................................................................................................2

1.1供水发展过程及现状 ..........................................................................2

1.2课题设计目的........................................................................................2

第二章 系统总体设计方案.........................................................................3

2.1控制要求................................................................................................3

2.2系统分析及基本流程...........................................................................4

第三章 硬件设计..............................................................................................6

3.1 PLC的介绍及选型 .........................................................................6

3.1.1 PLC的介绍 .............................................................................6

3.1.2 PLC选型 .....................................................................................7

3.2 其他硬件介绍及选型 ......................................................................9

3.2.1西门子MM440系列变频器主要参数 ........................................9

3.3 西门子MM440系列变频器主电路构成 .....................................10

3.3.1 主电路 .....................................................................................10

3.4 传感器介绍与选择 ......................................................................12

3.5 I/O分配表 ....................................................................................12

3.6 PLC接线图 ....................................................................................12

第四章 软件设计 .........................................................................................13

4.1 STEP软件介绍 ................................................................................13

4.1.1 PLC的PID参数设置和介绍 ...................................................14

4.2系统流程 ........................................................................................14

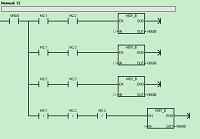

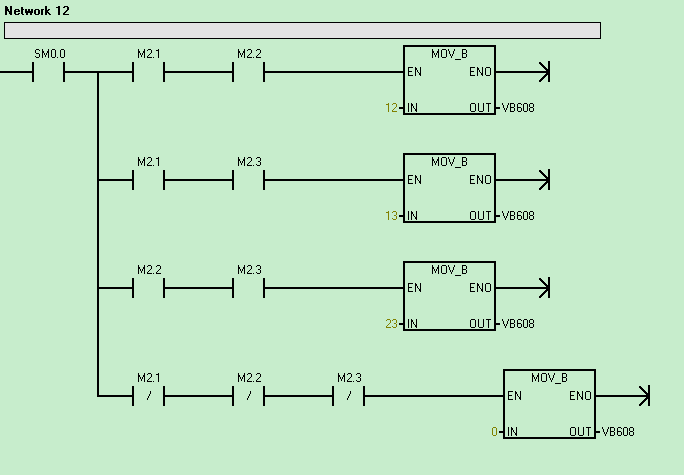

4.3梯形图 ..........................................................................................14

第五章 组态软件与PLC的通信设置 ............................................24

5.1 组态王简介 ...................................................................................24

5.2创建工程路径 ..............................................................................25

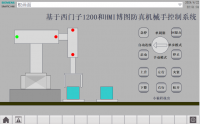

5.3创建组态画面 ................................................................................26

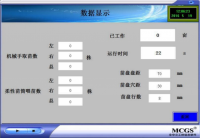

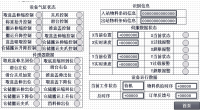

5.4变量和数据的定义 ........................................................................28

5.5构造数据库 ..................................................................................30

5.6 建立动画连接 ...............................................................................31

5.7 运行和调试 ...................................................................................33

5.8 数据采集的实现 ...........................................................................34

第六章 结论 ....................................................................................................39

致谢 .........................................................................................................................40

参考文献 .................................................................................................................41

附录 一 .................................................................................................................42

附录 二 .................................................................................................................43

参考文献

[1]陈建明.电气控制与PLC应用[M].北京:电子工业出版社,2006.

[2]吴中俊.可编程控制器原理及应用[M].北京:机械工业出版社,2003.

[3]廖常初.PLC编程及应用[M].北京:机械工业出版社,2007.

[4]西门子公司编.SIMATICS7-200系统手册[M].北京:机械工业出版社,2002.

[5]Gurkan Zenginobuz,Isik Cadirci.Performance Optimization of Induction Motors During Voltage-Controlled Soft Starting[J].IEEE TRANSACTIONS ON ENERGY CONVERSION,2003,6(5):54~58.

[6]王永华.现代电气及可编程控制技术[M].北京:北京航空航天大学,2002.

[7]周万珍,高鸿斌.PLC分析与设计应用[M].北京:电子工业出版社,2004.

[8]张万忠,刘明芹.电器与PLC控制技术[M].北京:化学工业出版社,2003.

[9]殷洪义.可编程序控制器选择﹑设计与维护[M].北京:机械工业出版社,2003.

[10]苏昆哲.深入浅出西门子WinCC V6[J].北京:北京航空航天大学出版社,2004,7(2):32~38.

[11]王也仿.可编程序控制器应用技术[M].北京:机械工业出版社,2001.

[12]西门子公司编.SIMATICMM440变频器系统手册[M].北京:机械工业出版社,2002

[13]马小军.可编程控制器及应用[M].南京:东南大学出版社,2007.

[14]谢克明,夏路易.可编程控制器原理与程序设计[M].北京:电子工业出版社,2002.

[15]严盈富.监控组态软件与PLC入门[M].北京:人民邮电出版社,2007.

[16]袁任光.可编程序控制器选用手册[M].北京:机械工业出版社,2002.

http://www.bysj1.com/html/6486.html

http://www.bysj1.com/html/6469.html

http://www.bysj1.com/html/6483.html