液压传动和气压传动的发展与应用

液压传动和气压传动称为流体传动,是根据17世纪帕斯卡提出的液体静压力传动原理而发展起来的一门新兴技术,是工农业生产中广为应用的一门技术。如今,流体传动技术水平的高低已成为一个国家工业发展水平的重要标志。

Hydraulic and pneumatic transmission fluid called Transmission is based on the 17th century MPa static pressure of the liquid transmission and development of the principle of a new and emerging technologies, in industrial and agricultural production is widely used in a technology. Today, transmission fluid, high-level technology has become a national industrial development and an important symbol.

1795年英国约瑟夫•布拉曼(Joseph Braman,1749-1814),在伦敦用水作为工作介质,以水压机的形式将其应用于工业上,诞生了世界上第一台水压机。1905年将工作介质水改为油,又进一步得到改善。

• 1795 British Bulaman Joseph (Joseph Braman ,1749-1814), in London water as a working medium, in the form of pressure to be applied in industry, the birth of the world's first hydraulic press. 1905 will be oil water media work, and further improved.

第一次世界大战(1914-1918)后液压传动广泛应用,特别是1920年以后,发展更为迅速。液压元件大约在 19 世纪末 20 世纪初的20年间,才开始进入正规的工业生产阶段。1925 年维克斯(F.Vikers)发明了压力平衡式叶片泵,为近代液压元件工业或液压传动 的逐步建立奠定了基础。20 世纪初康斯坦丁•尼斯克(G•Constantimsco)对能量波动传递所进行的理论及实际研究;1910年对液力传动(液力联轴节、液力变矩器等)方面的贡献,使这两方面领域得到了发展。

World War I (1914-1918) after hydraulic transmission widely used, especially after 1920, developed more rapidly. Hydraulic Components about the 19th century and the early 20th century, 20 years before they enter the formal start of industrial production stage. 1925 Weikeshi (F. Vikers) invented the pressure balanced vane pump for the hydraulic components of modern industrial or hydraulic transmission for the gradual establishment of a foundation. The early 20th century, Emil • Nishike (G • Constantimsco) by the transfer of energy fluctuations of the theoretical and practical research in 1910 on the hydraulic transmission (hydraulic coupling, hydraulic torque converter, etc.) of the contribution of so that both fields have been developed.

第二次世界大战(1941-1945)期间,在美国机床中有30%应用了液压传动。应该指出,日本液压传动的发展较欧美等国家晚了近 20 多年。在 1955 年前后 , 日本迅速发展液压传动,1956 年成立了“液压工业会”。近20~30 年间,日本液压传动发展之快,居世界领先地位。

The Second World War (1941-1945), the machine in the United States in 30% of the hydraulic transmission. It should be noted that the development of Japan hydraulic transmission, and other countries in Europe and the United States nearly 20 years later. In 1955 or thereabouts, the rapid development of hydraulic transmission Japan, in 1956 set up a "hydraulic industry will be." The past 20 to 30 years, Japan hydraulic drive the rapid development and the world's leading position.

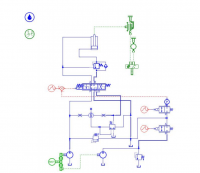

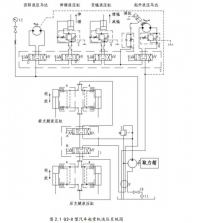

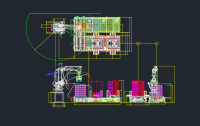

我国的液压工业开始于20世纪50年代,其产品最初应用于机床和锻压设备,后来又用于拖拉机和工程机械。自1964年开始从国外引进液压元件生产技术,同时自行设计液压产品以来,我国的液压元件生产以形成系列,并在各种机械设备上得到了广泛的使用。 目前,我国机械工业在认真消化、推广从国外引进的先进液压技术的同时,大力研制开发国产液压元件新产品﹙如中高压齿轮泵、比例阀、叠加阀及新系列中高压阀等﹚,加强产品可靠性和新技术应用的研究,积极采用国际标准和执行新的国家标准,合理调整产品结构,对一些性能差的不符合国家标准的产品采取逐步淘汰的措施。可以看出,液压传动技术在我国的应用与发展已经进入了一个崭新的历史阶段受压液体作为工作介质进行能量传递、转换与控制的传动型式称为液压传动。与机械传动比, 液压传动具有功率-质量比大、便于无级调速和过载保护、布局灵活方便等多种技术优势,作为现代机 械设备实现传动与控制的重要技术手段,在现代农业、制造业、电力煤炭工业、油气探采与化工、采 矿与冶金工程、交通运输工程、建材建筑业、航空航天与河海工程、科学实验装置、公共设施与保、 国防军事工程等领域获得了广泛应用。液压传动与控制的机械设备或装置中,能够实现某种特定功能的液压元件的组合,称为液压路。为了实现对某一机器或装置的工作要求,将若干特定的基本回路连接或复合而成的总体称为液压系统液压系统一般都是由动力部分、执行部分、控制部分和辅助部分所组成,各部分的功能及作用如下。

China's industrial hydraulic began in the 1950s, initially for its products and forging machine tool equipment, then used tractors and construction machinery. Since the beginning of 1964 the introduction of hydraulic components from abroad production technology, and design their own hydraulic products, China's production of hydraulic components to form a series, and the machinery and equipment are widely used. At present, China's machinery industry in serious digestion and promote the import of foreign advanced hydraulic technology, strong research and development of new products Domestic hydraulic components (such as the high-pressure pump gear, proportional valve, the valve stack and the new series of high-pressure valves, etc. ), the strengthening of product reliability and application of new technologies, an active use of international standards and the implementation of the new national standards, reasonable adjustment of product structure, and the poor performance of some countries which do not conform to standard products to the phasing out measures. Can be seen, hydraulic drive technology application in China and development have entered a new historical stage as a working pressure liquid medium for energy transfer, conversion and control of the transmission type known as hydraulic transmission. And the mechanical transmission ratio, a hydraulic power transmission - than quality, easy stepless speed regulation and overload protection, flexible layout, and other technological advantages, as a modern machinery and equipment to achieve the transmission and control of important technical means, in modern agriculture, manufacturing, electricity coal industry, oil and gas exploration and chemicals, mining and metallurgical engineering, transport engineering, and building materials industry, aerospace and Hehai engineering, scientific experimental device, public facilities and security, national defense and military projects in areas such as access to a wide range Application. Hydraulic and control mechanical equipment or devices, to achieve a particular function of a combination of hydraulic components, known as hydraulic Road. In order to achieve a particular machine or device on the work requirements, a number of specific basic loop connection or from the overall compound known as hydraulic system hydraulic system are generally part of the driving force for the implementation of the control of some parts and auxiliary components , the part of the function and role as follows.

动力元件的作用是将原动机的机械能转换成液体的压力能,指液压系统中的油泵,它向整个液压系统提供动力。液压泵的结构形式一般有齿轮泵、叶片泵和柱塞泵.液压动力元件起着向系统提供动力源的作用,是系统不可缺少的核心元件。液压系统是以液压泵作为系统提供一定的流量和压力的动力元件,液压泵将原动机(电动机或内燃机)输出的机械能转换为工作液体的压力能,是一种能量转换装置。

Dynamic element is the role of the original motivation converted into mechanical energy to the pressure of the liquid, in the hydraulic system that pumps it to the entire hydraulic system powered. Pump the general structure of a gear pump, the vane pump and piston pump. Hydraulic power system components to play the role of power source, is an indispensable core system components. Hydraulic system is a hydraulic pump system to provide a flow and pressure force components, the original motive of the hydraulic pump (motor or internal combustion engine) output can be converted into mechanical work to the pressure of liquids, is a kind of energy conversion devices.

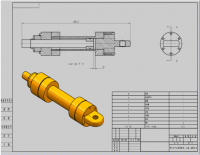

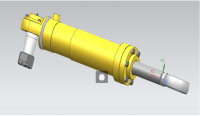

执行器部分(液压缸、液压马达和摆动液压马达)——将液体的压力能转变为机械能,用以驱动 工作机构的负载做功,实现往复直线运动、连续回转运动或摆动。 液压缸又称油缸,是一种将输入的液压能转换成机械能的能量转换装置,用来驱动工作机构作直线或小于360度的回转运动。液压缸具有结构简单,工作可靠,制造容易和使用维护方便等优点,是应用最广的液压执行元件。

Implementation of section (hydraulic cylinders, hydraulic motors and hydraulic motor Swing) - to the pressure of the liquid into mechanical energy to drive the load acting work, the realization of reciprocating linear motion, continuous rotary movement or swing. Also known as the fuel tank of hydraulic cylinder is a hydraulic input can be converted into mechanical energy conversion devices, used to drive linear or institutions work less than a 360-degree rotating movement. Hydraulic cylinder is simple, reliable, easy to manufacture and use of the advantages of easy maintenance, is the most widely hydraulic actuators.

例如转向缸在液压缸中被广泛应用。它在伸出的时候(液压杆从缸体中伸出),由于缸体一端是耳环,并没有被固定,所以在伸出的时候本身会转动。它被用于各种转向机构中。比如说产斗车的悬臂是由两个转向缸够成,它们控制悬臂的旋转,使铲斗能挖土。

For example, in the hydraulic cylinder to cylinder was widely used. It extended the time (in the hydraulic cylinder rod extending from), is due to end cylinder earrings, and have not been fixed, so the time itself will be extended rotation. It is used to all kinds of institutions. For example, the cantilevered box production by two-to-cylinder enough, they cantilever control the rotation of the bucket can excavators.

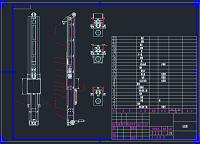

最简单的执行器的构造是一个简单作用的液压缸体,液体在活塞的一边,仅在一个方向产生输出的力和运动。重力或外部的弹簧能使活塞回归到起始位置,而液体重新回到缸体中。当活塞杆进行曲伸时候,一个双作用的缸体将液体从活塞的任一端产生力或运动。活塞外直径和缸体内直径之间的密封必须能同时处理方向和运动的问题。此外,这里还可以是双端杆缸体,它通过缸体的后部盖增加了一个活塞杆伸展运动。

The simplest implementation of the structure is a simple role of the hydraulic cylinder and piston in the liquid side, in only one direction and movement of the output. Spring gravity or external Pistons can return to starting position, and return to the liquid in the cylinder. When the piston rod to Shen Qu, a dual role of the cylinder piston liquid from the end of a movement or. Detroit, in diameter and the diameter between the cylinder seal must be able to deal with the direction and movement problems. In addition, this can also be a dual-rod cylinder, the cylinder through the rear cover an additional rod stretching exercises.

一个典型的双作用液压缸,活塞伸展时产生的力会略大于收缩的力,虽然在每个活塞上收到的压力一致,但因为暴露在液压流体中的有效面积不同,因而力也不同。

A typical double-acting hydraulic cylinder and piston, the extension of the contraction will be slightly larger than the force, although each received pressure on the piston, but the exposure to the hydraulic fluid because of the effective area of different and therefore also of different.

另外一种执行器的变通类型是一个活塞式样缸体,采用直径活塞杆可适应各种环境,全活塞的直径设计,可在压力或冲击的环境中的在长行程的水平元件或垂直方向有负荷状态下,避免了活塞杆弯曲。

Another implementation of the modifications is a type cylinder piston design, the diameter of a piston rod can be adapted to various environment, the diameter of the entire piston design, in the pressure or the environment, the impact of the long journey level components or vertical direction load, avoid bending of the rod.

活塞连接在一个高强度的钢活塞杆上,活塞杆的另一端与连接活塞端。通常采用表面硬化或镀铬杆方式,使其表面的处理十分细腻,保证密封效果的长时间使用。活塞必须与缸体精确贴合,每个部份都是严格的柱体,而且是经过精密处理的,以产生平滑的输出运动。

Detroit connected to a high-strength steel rod, the rod with the other end of the Pistons-connected. Usually a surface hardening or chrome rod, it is very delicate surface to ensure the sealing effect of prolonged use. Pistons and cylinder must be precise to fit each part of the cylinder is strictly, but the precise handling, in order to create smooth movement of the output.

双作用缸体是最常用的液压缸体类型,提供两个方向的输出的行程。工业缸体还支持转向横拉杆以固定缸体、缸头和末端盖。

Double-acting cylinder is the most common type of hydraulic cylinder, providing the two directions of the output itinerary. Industrial cylinder transverse drawbars to support a fixed cylinder, cylinder head cover and terminal.

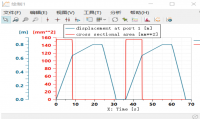

最新的工业双作用液压缸还加入了传感器反馈和一个电子液压伺服阀,从而能完成复杂的高速和位移控制。应用范围不仅包括生产机械机床、金属加工设备,还可以广泛使用在钢铁的执行器、核电厂控制、客用电梯等。

Dual role as industrial hydraulic cylinder has also joined the sensor feedback and an electronic hydraulic servo valve, allowing for the completion of the complex high-speed and displacement control. Application areas include not only production machinery machine tools, metal processing equipment, but also widely used in the iron and steel for the implementation of the nuclear power plant control, passenger lifts.

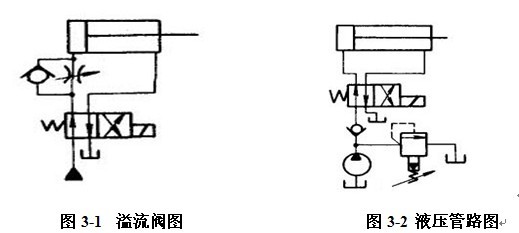

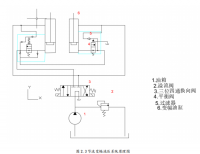

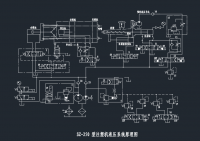

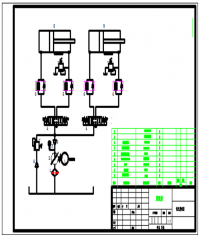

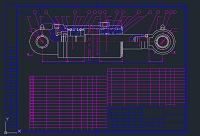

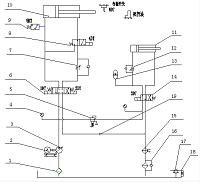

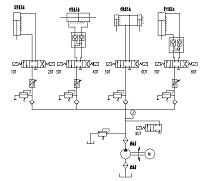

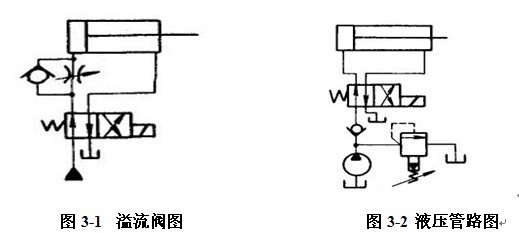

控制阀部分(各种压力、流量、方向控制阀及其他控制元件)——控制调节液压系统中从泵到执 行器的油液压力、流量和方向,从而控制执行器输出的力(转矩)、速度(转速)和方向以保证执行器动的主机工作机构完成预定的运动规律。 控制元件(即各种液压阀)在液压系统中控制和调节液体的压力、流量和方向。根据控制功能的不同,液压阀可分为村力控制阀、流量控制阀和方向控制阀。压力控制阀又分为益流阀(安全阀)、减压阀、顺序阀、压力继电器等;流量控制阀包括节流阀、调整阀、分流集流阀等;方向控制阀包括单向阀、液控单向阀、梭阀、换向阀等。根据控制方式不同,液压阀可分为开关式控制阀、定值控制阀和比例控制阀。

Control Valve part (all kinds of pressure, flow rate and direction control valves, and other control devices) - controlling the hydraulic system from the pump to the implementation of the oil pressure, flow rate and direction so as to control the implementation of the power output (torque ), velocity (speed) and direction to ensure the implementation of the Dynamic Host institutions completed the planned campaign laws. Control components (that is, all kinds of hydraulic valve) in the hydraulic system of control and regulation of fluid pressure, flow rate and direction. According to the different control, hydraulic valve can be divided into the village of control valves, flow control valve and control valve direction. Pressure control valve is divided into benefits flow valve (safety valve), the valve in order valve, the pressure relay; flow control valve including throttle adjustment valve, triage-flow valve; directional control valve including a one-way valve , the hydraulic control valve, the valve spindle, such as reversing valve. Under the control of different ways, hydraulic valve can be divided into switching control valves, fixed-value ratio control valve and control valve.

辅助部分(油箱、管件、过滤器、热交换器、蓄能器及指示仪表等)——用来存放、提供和回收 辅助元件包括油箱、滤油器、油管及管接头、密封圈、压力表、油位油温计等。

Supporting part (tanks, tubes, filters, heat exchangers, storage and instructions for instruments, etc.) - for storage, delivery and recovery support elements including tanks, Oil Filter, tubing and fittings, seals, pressure Table oil in dollars, such as oil temperature.

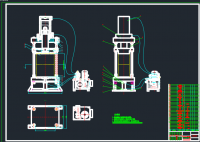

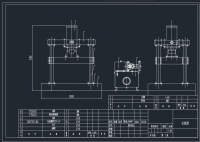

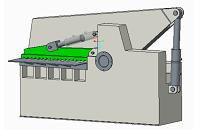

液压介质,实现液压元件之间的连接及传输载能液压介质,滤除液压介质中的杂质、 保持系统正常工作所需的介质清洁度,系统加热或散热,储存、释放液压能或吸收液 压脉动和冲出,显示系统压力、油温等。 压装机是对机械零部件进行安装以及拆卸为目的的设备,在机械加工以及维修行业中具有广泛的用途。目前国内的压装机,在技术上还是50年代沿用至今的样式和功能,属通用型油压机。这种压装机主要由鄂城重型机械厂和天津重型机械厂等厂家生产制造。这些产品结构简单,控制系统落后,功能单一,全部人工手动操作,没有自动测量和控制系统。在压装轮对时靠人工用尺测量,用眼观测压装油缸的行进位置;接近停止位置时,操作工人手动或脚踏开关,使油缸停止前进。这种全部人工操作的压装方式己延续了几十年,毫无大的改进。这种轮对压装机最主要的缺点是人工操作,同时生产效率低,一次压装合格率低,压装质量受人为因素影响大。

Hydraulic media, realizing the connection between the hydraulic components and hydraulic transmission medium can be contained, hydraulic filter impurities in the media, to keep the system necessary for the proper functioning media cleanliness, heating or cooling system, storage, the release of can be absorbed or hydraulic pressure pulsation and out of that system pressure, oil temperature, etc.. Pressure installed on the installation of mechanical parts and equipment for the purpose of demolition, in the mechanical processing and maintenance industry with a wide range of uses. Current domestic pressure installed in the 1950s or technically so far adopted the style and function, a common type hydraulic machine. Such pressure by the main installed Echengchongxingjixiean and Tianjin Chongxingjixiean manufacturers such as manufacturing. These products simple structure, the control system backward, single function, the manual operation of all, there is no automatic measurement and control systems. In the round with the pressure on labor at the foot measurement, with the fuel tank pressure with sharp eyes of the road position; location close to stop, manual workers or foot operated switch to the fuel tank to stop progress. All of this manual pressure with the approach has been extended several decades, there is no great improvement. This round of pressure on the capacity of the most important shortcoming is that it manual, low production efficiency at the same time, with a pass rate of low pressure, pressure with the quality of the human factors influence.

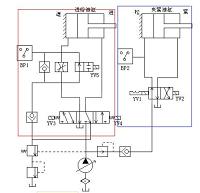

压装机的类型非常之多,用途不一,就他们的系统而言,有液压控制系统和液压传动系统。液压控制系统,是闭环系统,可对被控制量进行检测并加以反馈,系统按偏差调节原理工作,并控偏差信号的方向和大小进行自动调整控制系统有反馈,具有抗干扰能力,因而控制精度高。液压传动系统是开环系统,被控制量与控制量之间无联系,控制量是流量控制阀的开度或变量泵的调节参数,被控制量是执行机构的速度对被控制量不进行检测,系统没有修正执行机构偏差的能力。控制精度取决于元件的性能和系统整体的精度,控制精度较差,但调整简单性能指标侧重于静态特性,主要性能指标有调速范围,低速平稳性,速度刚度和效率。