超声换能器动力学分析

摘 要

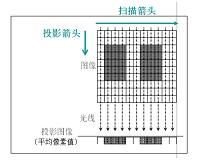

声频定向扬声器系统是一种可以使声音只沿固定方向传播的装置。该系统主 要通过超声波在空气中的非线性交互作用产生高指向性的可听声,从而革命性地 使声音信号控制在指定范围内以高指向方式传播。本文旨在分析声频定向扬声器 系统的关键组成部分——超声换能器的动态特性,并对换能器 的结构参数进行优化。根据理论分析结果,设计并制作一款输出声压较大、指向 性较高、失真较低的超声换能器。

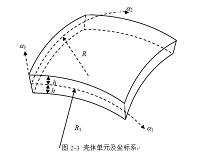

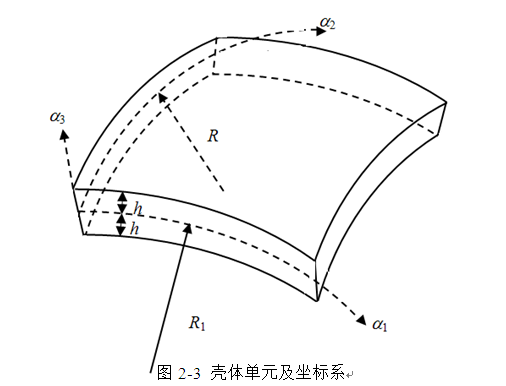

本文主要是根据压电板壳的基本理论,建立无限宽度一维圆柱波纹壳换能器

拉伸和弯曲耦合运动的理论动力学模型,并分析换能器在低频段动力学特性。存 在一个对弧段数 N 不敏感的谐振频率,结构中间点的弯曲位移幅值随着 N 的增大 而减小。引入剪切变形和转动惯量,建立无限宽度一维圆柱波纹壳换能器拉伸和 弯曲耦合运动的理论动力学模型。剪切变形和转动惯量使得换能器的谐振频率降 低,弯曲位移变大。且对于高阶模态,剪切变形和转动惯量的影响较大。基于已 建立的一维理论模型,建立了有限宽度圆柱波纹壳换能器二维结构的拉伸和弯曲 耦合运动的理论模型,分析宽度效应对换能器振动特性影响。横向边界约束使得 换能器的谐振频率随着宽/长比的减小而增大。随着宽/长比的增大,中间部分的弯

曲位移逐渐趋近一个常量,只在两横向边界附近 / l 0, 1,出现较大的改变。当

宽/长之比较大时,横向边界约束使得壳体的中间部分拉伸力增大。建立轴对称圆 环波纹壳换能器拉伸和弯曲耦合运动的理论模型,并分析换能器振动特性。换能 器一阶谐振点频率随着 N 的增大而降低,一阶振动模态主要集中在外部边界附近, 且对于 N 的变化不敏感。根据理论分析的结果,设计制作了一款超声换能器。经测试换能器的谐振频率约为 43kHz(设计频率 40kHz),换能器的 最大输出声压为 125dB, 3dB 波束宽度约为15°, 10dB 波束宽度约为30°。

关键词:声频定向,高指向性,PVDF 压电薄膜,圆柱波纹壳,压电换能器

目 录

第一章 绪 论 1

1.1 声频定向系统简介 1

1.2 研究背景 1

1.2.1 声频定向系统研究背景 1

1.2.2 超声 换能器研究背景 3

1.3 论文内容 5

第二章 超声换能器低频段振动特性 6

2.1 引言 6

2.2 压电壳体方程 7

2.3 换能器方程及其解 11

2.4 数值计算结果 13

2.5 本章小结 20

第三章 超声换能器高频段振动特性 21

3.1 引言 21

3.2 压电壳体方程 21

3.3 换能器方程及其解 23

3.4 数值计算结果 26

3.5 本章小结 30

第四章 有限宽度超声换能器振动特性 31

4.1 引言 31

4.2 有限宽度压电壳体方程 31

目 录

4.3 换能器方程及其解 35

4.4 数值计算结果 41

4.5 本章小结 44

第五章 轴对称超声换能器振动特性 45

5.1 引言 45

5.2 轴对称圆环波纹壳方程 45

5.3 换能器方程及其解 50

5.4 数值计算结果 52

5.5 本章小结 59

第六章 超声换能器设计制作及实验 60

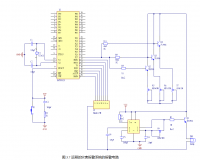

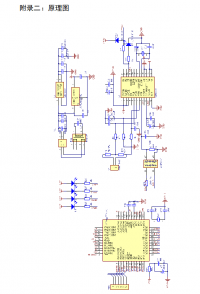

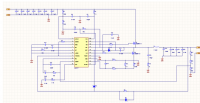

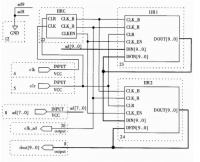

6.1 PVDF 压电薄膜特性 60

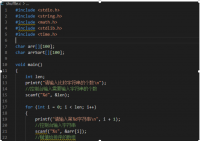

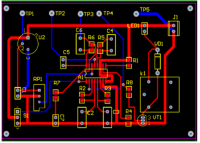

6.2 超声换能器设计制作 61

6.3 超声换能器实验测试 62

6.2.1 谐振频率测试 62

6.2.2 输出声压测试 64

6.2.3 指向性测试 65

6.3 本章总结 67

第七章 总结与展望 68

7.1 全文总结 68

7.2 工作展望 69

参考文献 71

致 谢 74

参考文献

[1] P. J. Westervelt. Parametric Acoustic Array. The Journal of the Acoustical Society of America.

1963, 35(4):535-537

[2] H. O. Berktay. Possible Exploitation of Non-Linear Acoustics in Underwater Transmitting Applications. J. Sound Vib. 1965, 2 (4):435-461

[3] M. F. Hamilton and D. T. Blackstock. Nonlinear Acoustics. Academic Press, Boston, 1998 [4] J. James, J. O. Norris. HSS white paper. USA:American Technology Corporation, 2005, 1-2

[5] M. Yoneyama, J. I. Fujimoto. The audio spotlight: An Application of nonlinear interaction of sound waves to a new type of loudspeaker design. The Journal of the Acoustical Society of America, 1983, 73(5):1532-1536

[6] T. Kamakura, M. Yoneyama, K. Ikegaya. Developments of parametric loudspeaker for practicaluse. 10th International Symposium on Nonlinear Acoustics, Kobe, Japan, 1984:147-150

[7] T. Kamakura, T. Yoneyama and K. Ikegaya. Studies for the Realization of Parametric Loudspeaker. Journal of Acoustic Society of Japan, 1985, 41(6):378–385

[8] T. Kamakura, K. Aoki, Y. Kumamoto. Suitable modulation of the carrier ultrasound for a parametric loudspeaker. Acustica, 1991, 73:215-217

[9] Kenichi Aoki, Tomoo Kamakura, Yoshiro Kumamoto. Parametric Loudspeaker Characteristics of Acoustic Field and Suitable Modulation of Carrier Ultrasound. Electronics and Communications in Japan. 1991, 74(9):76-80

[10] K. Aoki, T. Kamakura, Y. Kumamoto. Parametric loudspeaker-Applied Examples. Electronics and Communications in Japan. 1993, 76(8):1127–1137

[11] F. J. Pompei. The Use of Airborne Ultrasonics for Generating Audible Sound Beams. Journal of Audio Engineering Society. 1999, 47(9):726-731

[12] F. J. Pompei. Sound From Ultrasound: The Parametric Array as an Audible Sound Source:[PhD Thesis]. USA:Massachusettes Institute of Technology, 2002

[13] American Technology Corporation. Parametric transducer having an emitter film. USA, United States Patent, Publication number:US 20005/0100181, 2004-08-20

[14] American Technology Corporation. Piezoelectric film sonic emitter. USA, United States Patent,

Patent Number:6011855, 2000-01-04

[15] K. S. Tan, W. S. Gan, J. Yang, M. H. Er. Constant beamwidth beamformer for difference frequency in parametric array. 2003 IEEE International Conference on Acoustics, Speech and Signal Processing, 2003, 5:361-364

[16] F. A. Karnapi, W. S. Gan, Y. K. Chong. FPGA implementation of parametric loudspeaker system. Microprocessors and Microsystems, 2004, 28(5):261-272

[17] M. Tamura, T. Yamaguchi, T. Oyabe, and T. Yoshimi. Electroacoustic transducers with piezoelectric high polymer films, Audio Eng. Soc., 1975, 23(1):21–26.

[18] R. Lerch and G. M. Sesler. Microphones with rigidly supported piezopolymer membrane. J. Acoust. Soc. Amer., 1980, 67(4):1379–1381.

[19]J. S. Schoenwald and J. F. Martin.. PVF2 transducers for acous-tic ranging and imaging in air. in Proc. 1983 IEEE Ultrason. Symp., pp. 577–580.

[20] F. Harnisch, N. Kroemer, W. Manthey. Ultrasonic transducers with piezoelectric polymer foil.

Sens. Actuators A, 1991, 25–27:549–552.

[21] A. S. Fiorillo, B. Allota, P. Dasio, R. Francescons. An ultrasonic range sensor for a robotic fingertip. Sens. Actuators, 1988, 12:103–106.

[22] S. Edelman and A. S. DeReggi. Comments on electroacous- tic transducers with piezoelectric high polymer films. J. Audio Eng. Soc., 1976, 24(7):577–578.

[23] I. Veit. The piezoelectric PVDF-film—Its properties and ap-plication in electroacoustic transducers. presented at the 84th Conv. Audio Eng. Soc., Mar. 1–4, 1988, Paris, France.

[24] A. S. Fiorillo. Design and characterization of a PVDF ultra- sonic range sensor. IEEE Trans.

Ultrason., Ferroelect., Freq. Contr., 1992, 30(6):688–692.

[25] H. Naono, T. Gotoh, M. Matsumoto, and S. Ibaraki. Design of an electro-acoustic transducer using piezoelectric polymer film. presented at Audio Eng. Soc. Prepr. 58 conv., New York, NY, Nov. 4–7, 1977.

[26] R. Lerch. Electroacoustic transducers using piezoelectric polyvinylidene fluoride films. J. Acoust. Soc. Amer., 1979, 66(4):952–954.

[27] L. Capineri, A. S. Fiorillo, L. Masotti, and S. Rocchi. Piezopolymer transducer for ultrasonic imaging in air. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 1997, 44(1):36–43.

[28] H. Wang and M. Toda. Curved PVDF airborne transducer. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 1999, 46(6):1375-1386.

[29] M. Toda. Phase-matched air ultrasonic transducer using corrugated PVDF film with half

wavelength depth. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 2001, 48(6):1568-1574.

[30] M. Toda and S. Tosima. Theory of curved, clamped piezoelectric film, air-borne transducers.

IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 2000, 47(6):1421-1431.

[31] M. Toda and M. L. Thompson. Contact-type vibration sensors using curved clamped PVDF film. IEEE Sensors Journal, 2006, 6(5):1170-1177.

[32] A. S. Fiorillo. Noise analysis in air-coupled PVDF ultrasonic sensors. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 2000, 47:1432-1437.

[33]M. Toda and J. Dahl. PVDF corrugated transducer for ultrasonic ranging sensor. Sensors and Actuators A, 2007. 134(2):427-435.

[34] L. M. Xu, H. Li, J. F. Cao and Y. T. Li. Influence of phased array pattern on beam directivity.

International Journal of Innovative Computing, Information and Control, 2006, 2:449-456.

[35] L. M. Xu, J. F. Gao and D. G. Huang. Design and characterization of a PVDF ultrasonic acoustic transducer applied in audio beam loudspeaker. in Proc. IEEE International Conference on Mechatronics and Automation (ICMA 2005), 2005, 4:1992-1997.

[36] R. D. Mindlin. High frequency vibrations of piezoelectric crystal plates. Int. J. Solids Structures, 1972, 8:895-906.

[37] H. F. Tiersten. Linear Piezoelectric Plate Vibrations. New York: Plenum, 1969.

[38] J. S. Yang. The Mechanics of Piezoelectric Structures. Singapore: World Scientific, 2006.

[39] J. S. Yang. One-dimensional equations for planar piezoelectric curved bars. IEEE Trans.

Ultrason., Ferroelect., Freq. Contr., 2007, 54(10):2202-2207.

[40] H. P. Hu, C. Zhao, S. Y. Feng, Y. T. Hu and C. Y. Chen. Adjusting the resonant frequency of a PVDF bimorph power harvester through a corrugation-shaped harvesting structure. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 2008, 55(3):668-674.

[41] M. Toda. Cylindrical PVDF film transmitters and receivers for air ultrasound. IEEE Trans.

Ultrason., Ferroelect., Freq. Contr., 2002, 49(5):626-634.

[42] Chien Wei-zang, Fan Da-jun, Hwang Chien. Comparison of the Calculations of Three-Convolution Circular Arc Corrugated Diaphragms By Toroidal Shell Theory and By Orthogonal Anisotropy Plate Theory. Applied Mathematics and Mechanics, 1984, 25(1):1019-1027.

[43] L. M. Xu, M. Chen, H. L. Du, H. P. Hu, Y. T. Hu, H. Fan and J. S. Yang. Vibration characteristics of a corrugated cylindrical shell piezoelectric transducer. IEEE Trans. Ultrason., Ferroelect., Freq. Contr., 2008, 55(11):2502-2508.

age.asp?id=37 http://www.bysj1.com/page.asp?id=31 http://www.bysj1.com/page.asp?id=37 http://www.bysj1.com/show.asp?id=4414 http://www.bysj1.com/ http://www.bysj1.com/p