污水处理机的结构优化设计与仿真

设计总说明

工业文明的进步为社会带来了巨大的经济效益,却也为人类的生存环境带来了破坏,随着人们生活水平的不断提高,人们逐渐意识到保护生活环境的重要性.目前,在混合溶液的处理方面,有关部门每年都会投入大量资金,并且发布了一系列应对污泥处理的政策,来约束和指导各地区对污泥处理技术的研究和应用.因为污水处理离心机的应用在节约能源、减少污染物排放、污泥浓缩脱水和再次利用方面有这重要的意义,所以应加大对污水处理离心机的开发研究,以达到更有效地保护生态环境的目的.

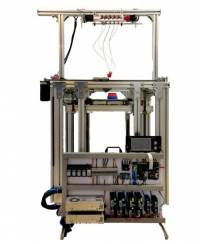

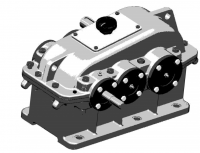

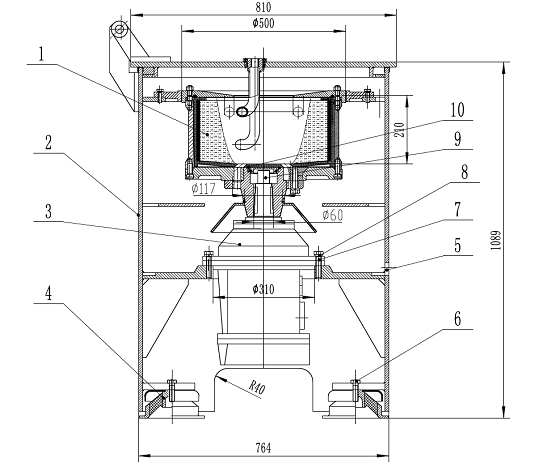

为此本文以无锡富岛科技有限公司生产的FD03-00离心污水机作为研究对象.其利用离心沉降的原理,利用污水各组分的质量不同,采用离心旋转产生离心力大小的不同,从液体中分离不溶颗粒,达到清洁混合油的目的的方法.沉降速度与粒子的密度、颗粒直径以及液体的密度和黏度有关,并随离心力亦即离心加速度的增大而加快.本项目对该设备的技术原理及现场问题进行研究,具有较好的实际应用价值和意义.

首先,通过查阅国内外相关文献,阐述了污泥脱水技术、离心分离技术、离心机的国内外现状及发展趋势,并分析了国内离心机的技术差距,明确了离心机的发展趋势;然后详细阐述了离心机的工作原理及工作过程,根据实际需要对转鼓材料进行选择.

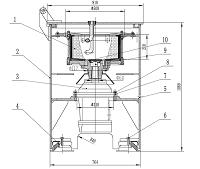

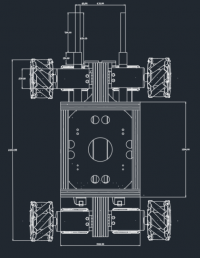

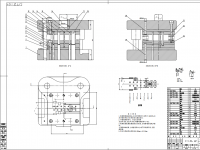

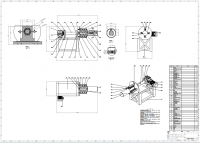

其次,对离心机基本参数和主要尺寸进行设计计算.对转鼓和外壳进行设计,并对各个部件进行详细介绍.参考国内外先进技术,根据离心力场内的流体力学的特点设计出转鼓的结构形式以改善间隙内液流分布状况,从而提高分离效果.

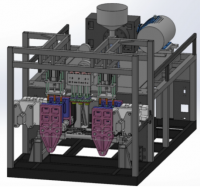

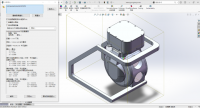

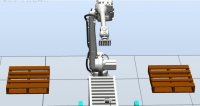

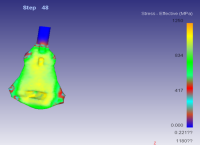

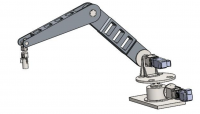

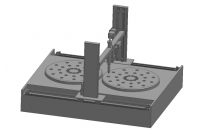

最后,选用UG软件对离心机进行三维建模并对关键部件转鼓进行了静力学分析和模态分析,为转鼓的结构设计提供了重要的理论依据,使得整个离心机的设计更具有可靠性,为进一步的优化设计以降低成本和提高机械效率提供了理论基础.

本设计需要达到的最终标准:(1)滤料在转鼓内的存留时间比卧式沉降离心机延长1—5min,从而提高分离效率.(2)本机工作时滤料由上部料斗的进料口进入,同时电机起动运转;滤料在由螺旋送料机构输送的同时被离心机进行沉降分离——被分离的滤液和滤渣各行其道,分别经离心机的出液口和出渣口被引出机外;整个操作过程是在全速、连续运转下自动进行.(3)离心机工作安全、可靠,运行平稳,产品质量稳定,操作维护简单,生产率为每小时排出渣3立方米.(4)本机结构紧凑,其进料口、出液口和出渣口便于连接到生产自动线上.按离心分离理论,一是向高速和大型发展(即提高其分离因数);二是延缓滤料(渣)在转鼓内的运行速度,达到充分脱液之目的.为克服现行螺旋卸料沉降离心机的缺点,本设计旨在提供一种能解决上述缺点和弊端的新型机种——立式沉降机.

关键词:污水处理离心机、转鼓部件、分离因数、三维建模、静力学分析

ABSTRACT

The development of industrial civilization as society has brought great economic benefits, but also brought destruction to the human’s living environment, people are increasingly aware of the importance of environment protection. At present, the processing of sewage sludge, the government will invest a lot of money, and issued a series of policies on sludge treatment and disposal, to restrain and guide the research and application of the various regions of the sludge treatment technology. Because sewage treatment centrifuges have this significance in promoting energy conservation, sludge dewatering and re-use, it should increase the research and development of sewage centrifuge, in order to achieve more effective protection of the environment.

So this paper to Wuxi-Island Technology Co, Ltd of FD03-00 centrifugal sewage machine for the study. Its use centrifugal sedimentation principle, the use of water quality of the components are different, the difference between the centrifugal force produced by the rotation centrifugal size from the liquid The method of separation of insoluble particles, to achieve the purpose of cleaning the mixed oil density and particle settling velocity, particle diameter, and the density and viscosity of liquid related, and that is the centrifugal acceleration and centrifugal force increases with speed up this project to the device technology research theory and field problems, specifically good practical application value and significance.

First of all, at home and abroad through the relevant literature review, we describe the sludge dewatering technology, centrifuge technology, the status quo and development trend of domestic and foreign centrifuge, and analyzed the technology gap between domestic centrifuges, centrifuge clear trends; and details The working principle and working process of the centrifuge, according to the actual needs of the drum material selection.

Secondly, the various components in detail. Reference foreign advanced technology, according to the characteristics of the centrifugal force field of fluid mechanics design drum structure in order to improve the flow distribution in the gap, thereby improving separation.

Finally, the choice of UG software for three-dimensional modeling of the centrifuge drum and key components were static analysis and modal analysis, structural design of the drum provides an important theoretical basis, making the whole centrifuge design is more reliable resistance.

The design needs to achieve the ultimate criteria: (1) filter in the drum retention time than horizontal sedimentation centrifuge extend 1-5min, thereby improving separation efficiency (2) that the unit operates from the upper hopper into the filter. discharge port entry, while the motor starting operation; filter at the same time by the screw feed mechanism is subjected to settling separation delivery of centrifuge - separated filtrate and residue prevails, respectively, through a liquid outlet and a cinder notch centrifuges are leads outside the machine; the whole operation is at full speed, continuous operation under automatic (3) centrifuge work safe, reliable, stable, stable product quality, simple operation and maintenance, a production rate of 3 cubic meters per hour discharge residue (4. ) The machine is compact, its inlet, a liquid outlet and a cinder notch for easy connection to the production line by automatic centrifugal separation theory, one is to develop high-speed and large-scale (ie, improve its separation factor); the second is to delay filter (slag) speed in the drum to achieve the purpose of full deliquoring to overcome the shortcomings of existing spiral unloading settlement centrifuges, the design is intended to provide a can solve the above drawbacks and disadvantages of the new models - vertical sedimentation machine.

Keywords: Centrifuge drum parts、 sewage treatment、separation factor、 three-dimensional modeling、static analysis

目 录

第1章 绪论 1

1.1引言 1

1.2离心机的特点及应用范围 3

1.3离心机的发展概况 3

1.4离心式污水处理机的研究意义及主要任务 5

1.4.1 本课题研究的意义 5

1.4.2本课题研究的任务 5

1.5离心式污水处理机研究指导思想 6

1.6本章小结 6

第2章 离心式污水处理机设计前期理论与计算准备 7

2.1离心式污水处理机的基本结构 7

2.2离心式污水处理机的工作原理 8

2.3转鼓部件材料选择 8

2.4离心机的配套设备 9

2.5离心机润滑方式选择 10

2.6本章小结 10

第3章 离心机的特性及参数计算 11

3.1 离心力场的概念与基本特性 11

3.1.1离心力和分离因数 11

3.1.2离心力场 12

3.1.3离心液压 12

3.1.4分离的过程 12

3.1.5生产能力 13

3.2离心机主要尺寸设计计算 13

3.2.1转鼓壁厚 13

3.3本章小结 15

第4章 离心机转鼓有限元分析 17

4.1有限元分析软件的选用 17

4.2离心污水处理机的三维建模与装配 17

4.1转股机构的静力学分析 19

4.1本章小结 27

第5章 论文总结 29

参考文献 31

致 谢 33

参考文献

[1]俞雷霖,奚立峰,俞如友.离心分离技术的国内现状国外进展及大规模定制设计[J].化学世界,2006,1 l:393—398.

[2]孙启才,金鼎五.离心机原理结构与设计计算[M].北京:机械工业出版社,1987.

[3]王寒冰,马春和,李霞.影响离心机分离效果的原因分析及对策[J].炼油与化

工,2004,1 5(2):43-44.

[4]孙步功.适于黄河泥沙分离的碟式离心机设计与试验研究[DI.兰州:兰州理工大学,

2004.

[5]朱企新,许莉,谭蔚等译.固液两相过滤及分离技术[M].北京:化学工业出版社,

2005.178—180.

[6]Barrye,Bershad.Industrial Centrifugation Technology[J].化工装备技术,1991,12(2):48-53.

[7]W-ELeung.Industrial Centrifugation Technology[M].MeGraw-Hill Inc,New York,1988.

[8]梁金龙,章琪.国外过滤与分离机械发展概况[J].过滤与分离,2000,lO(4):1-7.

[9]谭蔚,石建明,朱企新,赵扬.IN#l-过滤与分离技术的进展[J].化工机械,2002,

29(4):245-248.

[10]龚俊,孙步功,辛舟.碟式分离机整机动平衡方法及应用[J].兰州理工大学学

报,2004,38(5).

[11]中国通用机械分离机械协会秘书长郑芳顺,我国分离机械业亟待迈大步[N].中国化工报,2002.

[12]施震荣.工业离心机选用手册[M].北京:化学工业出版社,1999.3.

[13]Calin I.Anghel.A study concerning elastic analysis of disk centrifugal separators

[J].Computer methods in applied mechanics and engineering,1 997,1 44:275-285.

[14]魏东.国产离心机在炼化厂污泥脱水中的应用[J].炼油设计,2002,32(1):55—57.

[15]Degenhardt P.M.Dewatering of PVC by decanter centrifuges.Filtration and Separation,

1 996,34(5):447-449.

[16]刘儿清,范德顺,黄钟编.固液分离与工业水处理[M].北京:中国石化出版2001.3

[17]孙步功,龚俊,辛舟.黄河泥沙碟式分离机转鼓有限元分析[J].甘肃农业大学学报,2008,3.

http://www.bysj1.com/ http://www.bysj1.com/html/5115.html http://www.bysj1.com/html/3584.html