基于西门子S7-1500PLC TIA Portal 的水箱进给 PID 控制系统设计

摘要 随着近年来控制技术的发展和电子与机械相结合,PLC 作为一种以输入输出数字信号

和模拟信号,通过电脑程序控制机械运作微处理器数字运算控制器也越来越受到重视。本毕

业设计为基于 TIA Portal 的水箱控制系统优化设计。本设计着眼于可以将 PLC-1500 与 PID

控制相结合的 TIA 软件,通过 TIA 软件可以较好地同时进行程序的编写与仿真,具有及时性

和可控性。通过 PLC 的设计优化,控制水泵的运行起止,从而可以控制水箱的液位与温度。

本设计包括了 PLC 程序以及控制面板程序,可以通过控制面板以控制 PLC 程序的运行,即控

制水泵的运行。但是如果仅仅依靠 PLC 程序控制依旧会遇到反馈慢,收到了反馈无法及时自

动调节等问题。为了可以更好的精确控制机械的运行,本设计同时采用了 PID 控制,大大将

强了反馈的强度。因为温度与液位的变化是两个至关重要的变量,故采用了闭环控制而非开

环控制。经过反复的测试,本设计可以满足利用温度和液位控制水泵进行一系列有预案的运

行。关键词:PLC-1500 PID 控制 温度控制 液位控制

引 言

科技发展飞速,近年来电脑集成化的规模快速提高。PLC 技术取得了长足的发展,一开

始的一位系统经过进一步的改良成为了十六位和三十二位系统。其内部主核心也得到了发

展,实现了多通道处理。当代 PLC 发展势头强劲,这不仅仅体现在性能的改善方面,同样体

现在其价格的下降,性能的拓宽,速度更快等方面。PLC 日渐成为控制系统的核心部分。目

前为止,PLC 有许多著名的生产厂家,国内国外都有几个。与此同时,生产生活中对控制的

要求也越来越高,比如现在的疫情严重,生物制药对液体的温度和液位都有比较高的要求,

生产厂家需要严格的控制水泵进水排水。如果仅仅依靠人力,无法满足瞬时性和精确性。而

且现代生产都是大批量格式化的生产,一旦有一个环节出错那么会影响整批产品的质量,人

为把关的主观因素太多,而且如果是晚上加工的话会面临人手不够的问题。所以 PLC 技术就

进入了人们的视野。PLC 可以很好的控制运行,而且可以同时兼顾温度控制与液位控制。

目录

引言························································································ 6

第一章 绪论·············································································· 7

1.1 本设计的描述·················································································· 7

1.2 系统的功能····················································································· 7

第二章 了解 PLC 和 PID······························································· 8

2.1 何为 PLC························································································ 8

2.2 何为 PID························································································ 9

2.3 如何将 PLC 和 PID 结合····································································· 10

第三章 控制装置的设计与选用······················································ 11

3.1 元件选用························································································ 11

3.1.1 CPU 的选用·················································································· 11

3.1.2 KTP900 触摸屏选用····································································· 12

3.2 液位、温度传感器选用··································································· 12

3.3 水泵的选型····················································································· 14

3.4 接线图··························································································· 19

3.4.1 变频器接线图············································································ 20

3.4.2 加热控制器和温度变送器····························································· 22

3.4.3 其他部分接线图········································································· 23

第四章 “TIA Portal ”的软件添加与程序调试······························· 25

4.1 项目的建立····················································································· 25

4.2 硬件模块························································································ 26

2

4.3 以太网址························································································ 28

4.4 编辑 PLC 变量表·············································································· 29

4.5 PID 选用························································································ 29

4.6 PLC 主程序编写··············································································· 31

4.6.1 液面程序编写············································································ 31

4.6.2 被控对象的处理········································································· 32

4.6.3 Cyclic interrupt 的编写···························································· 35

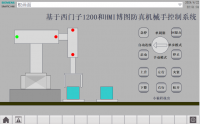

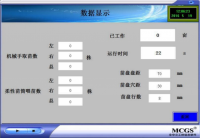

4.7 HMI 界面························································································ 36

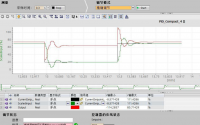

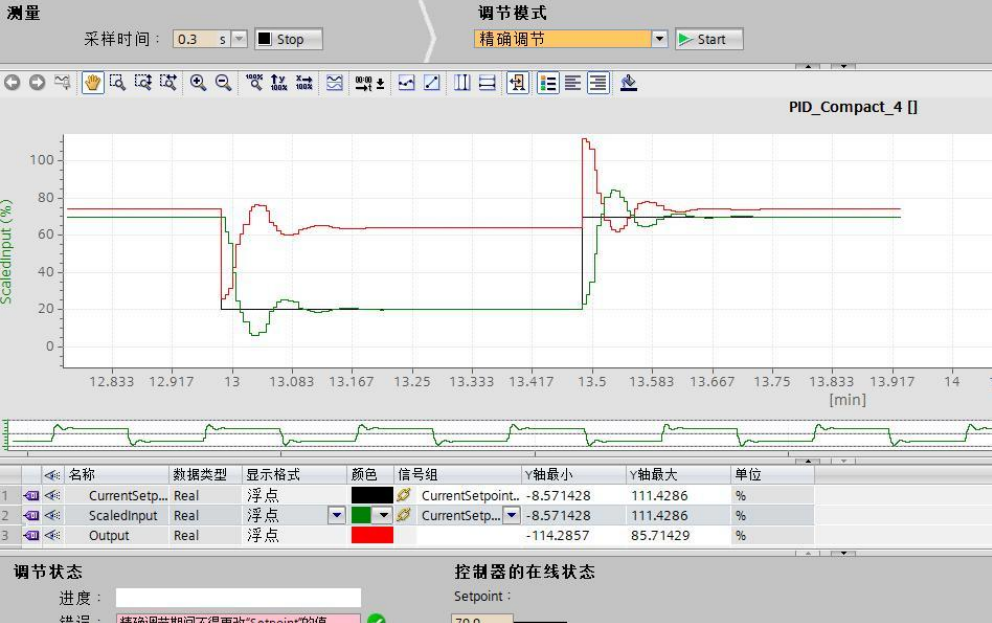

第五章 PID 的仿真调试······························································· 37

5.1 PID 仿真调节·················································································· 37

5.2 程序的仿真调试·············································································· 38

5.3 仿真调试结果分析··········································································· 40

结论·············································································· 42

致谢························································································ 43

参考文献········································································· 44

参考文献

[1] 廖常初.S7-12001500PLC 应用技术[J].北京.机械工业出版社.2017.11

[2] 冯洪玉.S7-300/400 系列 PLC 应用设计指南[J].北京.机械工业出版社.2016.04

[3] 孟爱华.工业自动化集成控制系统[G].西安.西安电子科技大学出版社.2020.01

[4] 黄有全.PLC 应用技术[J].北京.机械工业出版社.2012.07

[5] 张丽珂.PLC 基础教程[J].机械工业出版社.2020

[6] 王坤.基于西门子 PLC 的钢包智能烘烤系统设计[D].装备维修技术.2021.第 19 期

[7] 韩长利.陈鹏,电气工程及其自动化的智能化技术应用研究[N].环球市场.2020.第 8 期

[8] 祁建新.PLC 在铅粉球磨机自动化控制系统改造中的应用[D].山东工业技术.2013.第 12 期

[9] 西门子 S7-200 系列 PLC 编程指令与梯形图快速入门[K].西门子公司.2018. [10] 西门子温度 PID 控制[K].西门子公司.2015. [11] WinCC 组态[K].西门子公司.2016. [12] 罗伯特.诺顿.机械设计[J].机械工业出版社.2016.06. [13] PLC 实用技术[J].科学出版社.2005

[14] 张运刚.从入门到精通[J].西门子 S7-300/400PLC 技术与应用.人民邮电出版社.2005

[15] PLC 应用技术(西门子)[J].中国劳动社会保障出版社.2014.2