车床与机械加工

Lathes

车床

Lathes are machine tools designed primarily to do turning, facing, and boring. Very little turning is done on other types of machine tools, and none can do it with equal facility. Because lathes also can do drilling and reaming,their versatility permits several operations to be done with a single setup of the workpiece. Consequently, more lathes of various types are used in manufacturing than any other machine tool.

车床主要是为了进行车外圆、车端面和镗孔等项工作而设计的机床。车削很少在其他种类的机床上进行,而且任何一种其他机床都不能像车床那样方便地进行车削加工。由于车床还可以用来钻孔和铰孔,车床的多功能性可以使工件在一次安装中完成几种加工。因此,在生产中使用的各种车床比任何其他种类的机床都多。

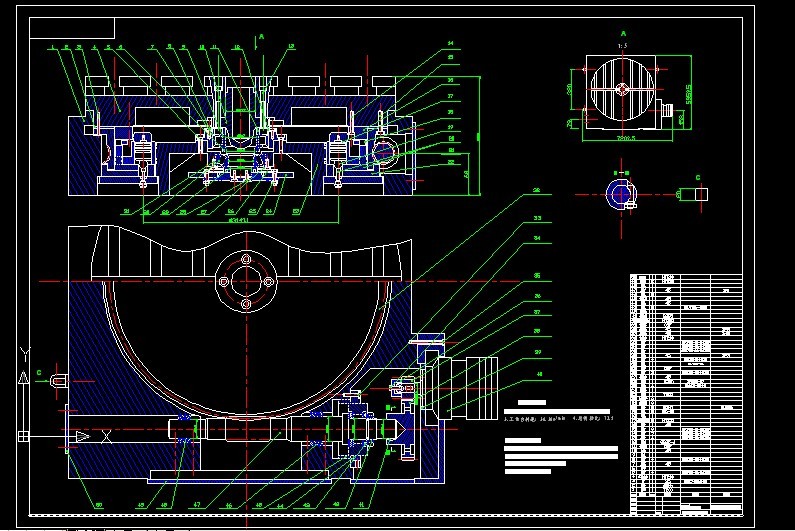

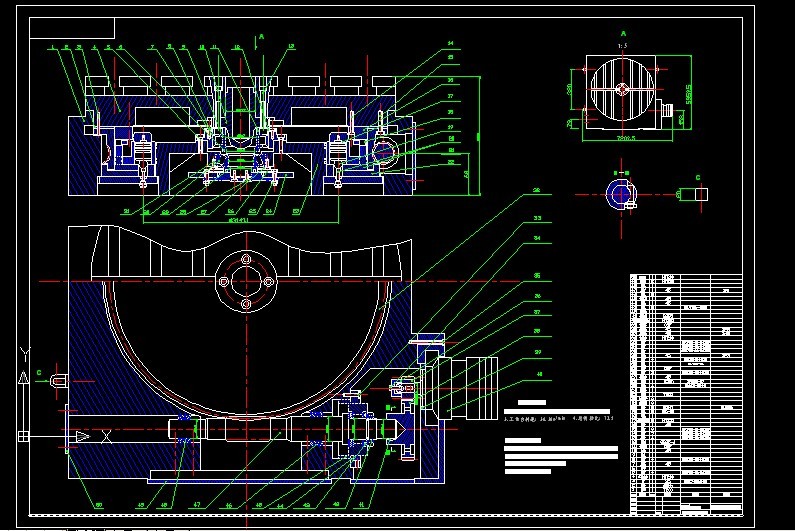

The essential components of a lathe are the bed, headstock assembly,tailstock assembly, carriage assembly, and the leadscrew and feed rod.

车床的基本部件有:床身、主轴箱组件、尾架组件、溜板组件、丝杠和光杠。

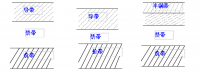

The bed is the backbone of a lathe. It usually is made of well-normalized or aged gray or nodular cast iron and provides a heavy, rigid frame on which all the other basic components are mounted. Two sets of parallel, longitudinal ways, inner and outer, are contained on the bed, usually on the upper side.Some makers use an inverted V-shape for all four ways, whereas others utilize one inverted V and one flat way in one or both sets. They are precision-machined to assure accuracy of alignment. On most modem lathes the ways are surface-hardened to resist wear and abrasion, but precaution should be taken in operating a lathe to assure that the ways are not them usually means that the accuracy of the entire lathe is destroyed.

床身是车床的基础件。它通常是由经过充分正火或时效处理的灰铸铁或者球墨铸铁制成。它是一个坚固的刚性框架,所有其他基本部件都安装在床身上。通常在床身上有内外两组平行的导轨。有些制造厂对全部四条导轨都采用导轨尖顶朝上的三角形导轨(即山形导轨),而有的制造厂则在一组中或者两组中都采用一个三角形导轨和一个矩形导轨。导轨要经过精密加工,以保证其直线度精度。为了抵抗磨损和擦伤,大多数现代机床的导轨是经过表面淬硬的,但是在操作时还应该小心,以避免损伤导轨。导轨上的任何误差,常常意味着整个机床的精度遭到破坏。

The headstock is mounted in a fixed position on the inner ways, usually at the left end of the bed. It provides a powered means of rotating the work at various speeds. Essentially, it consists of a hollow spindle, mounted in accurate bearings, and a set of transmission gear~ similar to a truck transmission-through which the spindle can be rotated at a number of speeds.Most lathes provide from 8 to 18 speeds, usually in a geometric ratio, and on modem lathes all the speeds can be obtained merely by moving from two to four levers. An increasing trend is to provide a continuously variable speed range through electrical or mechanical drives.

主轴箱安装在内侧导轨的固定位置上,一般在床身的左端。它提供动力,并可使工件在各种速度下回转。它基本上由一个安装在精密轴承中的空心主轴和一系列变速齿轮——类似于卡车变速箱——所组成。通过变速齿轮,主轴可以在许多种转速下旋转。大多数车床有8~18种转速,一般按等比级数排列。而且在现代机床上只需扳动2~4个手柄,就能得到全部转速。一种正在不断增长的趋势是通过电气的或者机械的装置进行无级变速。

Because the accuracy of a lathe is greatly dependent on the spindle, it is of heavy construction and mounted in heavy bearings, usually preloaded tapered roller or ball types. The spindle has a hole extending through its length, through which long bar stock can be fed. The size of this hole is an important dimension of a lathe because it determines the maximum size of bar stock that can be machined when the material must be fed through spindle.

由于机床的精度在很大程度上取决于主轴,因此,主轴的结构尺寸较大,通常安装在预紧后的重型圆锥滚子轴承或球轴承中。主轴中有一个贯穿全长的通孔,长棒料可以通过该孔送料。主轴孔的大小是车床的一个重要尺寸,因为当工件必须通过主轴孔供料时,它确定了能够加工的棒料毛坯的最大尺寸。

The tailstock assembly consists, essentially, of three parts. A lower casting fits on the inner ways of the bed and can slide longitudinally thereon,with a means for clamping the entire assembly in any desired location. An upper casting fits on the lower one and can be moved transversely upon it, on some type of keyed ways, to permit aligning the tailstock and headstock spindles. The third major component of the assembly is the tailstock quill.This is a hollow steel cylinder, usually about 51 to 76 mm (2 to 3 inches) in diameter, that can be moved several inches longitudinally in and out of the upper casting by means of a handwheel and screw.

尾架组件主要由三部分组成。底板与床身的内侧导轨配合,并可以在导轨上做纵向移动。底板上有一个可以使整个尾架组件夹紧在任意位置上的装置。尾架体安装在底板上,可以沿某种类型的键槽在底板上横向移动,使尾架能与主轴箱中的主轴对正。尾架的第三个组成部分是尾架套筒。它是一个直径通常大约在51—76 mm(2—3英寸)之间的钢制空心圆柱体。通过手轮和螺杆,尾架套筒可以在尾架体中纵向移人和移出几英寸。

The size of a lathe is designated by two dimensions. The first is known as maximum diameter of work that can be rotated on a lathe. It is approximately twice the distance between the line connecting the lathe centers and the nearest point on the ways. The second size dimension is the maximum distance between centers. The swing thus indicates the maximum workpiece diameter that can be turned in the lathe, while the distance between centers.

车废的规格用两个尺寸表示。第一个称为车床床面上最大加工直径。这是在车床上能够旋转的工件的最大直径。它大约是两顶尖连线与导轨上最近点之间距离的两倍。第二个规格尺寸是两顶尖之间的最大距离。车床床面上最大加工直径表示在车床上能够车削的最大工件直径,而两顶尖之间的最大距离则表示在两个顶尖之间能够安装的工件的最大长度。

Engine lathes are the type most frequently used in manufacturing. They are heavy-duty machine tools with all the components described previously and have power drive for all tool movements except on the compound rest. They commonly range in size from 305 to 610 mm ( 12 to 24 inches) swing and from 610 to 1 219 mm (24 to 48 inches) center distances, but swings up to 1 270 mm (50 inches) and center distances up to 3 658 mm (12 feet) are not uncommon. Most have chip pans and a built-in coolant circulating system. Smaller engine lathes-with swings usually not over 330 mm (13 inches) also are available in bench type, designed for the bed to be mounted on a bench or cabinet.

普通车床是生产中最经常使用的车床种类。它们是具有前面所叙述的所有那些部件的重载机床,并且除了小刀架之外,全部刀具的运动都有机动进给。它们的规格通常是:车床床面上最大加工直径为305~610 mill(12~24英寸);两顶尖之间距离为610~1 219 mm(24~48英寸)。但是,床面上最大加工直径达到1 270mm(50英寸)和两顶尖之间距离达到3 658 mm(12英尺)的车床也并不少见。这些车床大部分都有切屑盘和一个安装在内部的冷却液循环系统。小型的普通车床——车床床面最大加工直径一般不超过330mm(13英寸)——被设计成台式车床,其床身安装在工作台或柜子上。

Although engine lathes are versatile and very useful, because of the time required for changing and setting tools and for making measurements on the workpiece, they are not suitable for quantity production. Often the actual chip-production time is less than 30% of the total cycle time. In addition, a skilled machinist is required for all the operations, and such persons are costly and often in short supply. However, much of the operator's time is consumed by simple, repetitious adjustments and in watching chips being made.Consequently, to reduce or eliminate the amount of skilled labor that is required, turret lathes, screw machines, and other types of semiautomatic and been highly developed and are widely used in manufacturing.

虽然普通车床有很多用途,是很有用的机床,但是更换和调整刀具以及测量工件花费很多时间,所以它们不适合在大量生产中应用。通常,它们的实际加工时间少于其总加工时间的30%。此外,需要技术熟练的工人来操作普通车床,这种工人的工资高而且很难雇到。然而,操作工人的大部分时间却花费在简单的重复调整和观察切屑产生过程上。因此,为了减少或者完全不雇用这类熟练工人,六角车床、螺纹加工车床和其他类型的半自动和自动车床已经很好地研制出来,并已经在生产中得到广泛应用。

Machining

机械加工

Turning

车削

Engine lathe The engine, one of the oldest metal removal machines, has a number of useful and highly desirable attributes. Today these lathes are used primarily in small shops where smaller quantifies rather than large production rims are encountered.

普通车床普通车床作为最早的金属切削机床中的一种,目前仍然有许多有用的和为人们所需要的特性。现在,这些机床主要用在规模较小的工厂中,进行小批量的生产,而不是进行大批量的生产。

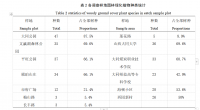

Tolerances for the engine lathe depend primarily on the skill of the operator. The design engineer must be careful in using tolerances of an experimental part that has been produced on the engine lathe by a skilled operator. In redesigning an experimental part for production, economical tolerances should be used.

普通车床的加工偏差主要取决于操作者的技术熟练程度。设计工程师应该认真地确定由熟练工人在普通车床上加工的试验零件的公差。在把试验零件重新设计为生产零件时,应该选用经济的公差。

The engine lathe has been replaced in today's production shops by a wide variety of automatic lathes such as turret lathes, automatic screw machines, and automatic tracer lathes.

在现代的生产车间中,普通车床已经被种类繁多的自动车床所取代,诸如六角车床、自动螺丝车床和自动仿形车床。

Turret Lathes Production machining equipment must be evaluated now, more than ever before, in terms of ability to repeat accurately and rapidly. Applying this criterion for establishing the production qualification of a specific method, the turret lathe merits a high rating.

六角车床对生产加工设备来说,目前比过去更着重评价其是否具有精确的和快速的重复加工能力。应用这个标准来评价具体的加工方法,六角车床可以获得较高的质量评定。

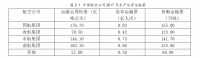

In designing for low quantifies such as 100 or 200 parts, it is most economical to use the turret lathe. In achieving the optimum tolerances possible on the turret lathe, the designer should strive for a minimum of operations.

在为小批量的零件(100~200件)设计加工方法时,采用六角车床是最经济的。为了在六角车床上获得尽可能小的公差值,设计人员应该尽量将加工工序的数目减至最少。

Automatic Screw Machines Generally, automatic screw machines fall into several categories; single-spindle automatics, multiple-spindle automatics and automatic chucking machines. Originally designed for rapid, automatic production of screws and similar threaded parts, the automatic screw machine has long since exceeded the confines of this narrow field, and today plays vital role in the mass production of a variety of precision parts.

自动螺丝车床 自动螺丝车床通常被分为以下几种类型:单轴自动、多轴自动和自动夹紧车床。自动螺丝车床最初是被用来对螺钉和类似的带有螺纹的零件进行自动化和快速加工的。但是,这种车床的用途早就超过了这个狭窄的范围。现在,它在许多种类的精密零件的大批量生产中起着重要的作用。

Quantities play an important part in the economy of the parts machined or the automatic screw machine. Quantities less than 1 000 parts may be mort economical to set up on the turret lathe than on the automatic screw machine. The cost of the parts machined can be reduced if the minimum economical la size is calculated and the proper machine is selected for these quantities.

工件的数量对采用自动螺丝车床所加工的零件的经济性有较大的影响。如果工件的数量少于10000件,在六角车床上进行加工比在自动螺丝车床上加工要经济得多。如果计算出最小经济批量,并且针对工件批量正确地选择机床,就会降低零件的加工成本。

Automatic Tracer Lathes Since surface roughness depends greatly upon material turned, tooling, and feeds and speeds employed, minimum tolerances that can be held on automatic tracer lathes are not necessarily the most economical tolerances.

自动仿形车床 因为零件的表面粗糙度在很大程度上取决于工件材料、刀具、进给量和切削速度,采用自动仿形车床加工所得到的最小公差不一定是最经济的公差。

In some cases, tolerances of ±0.05mm are held in continuous production using but one cut. Groove width can be held to ±0. 125mm or some parts. On high-production runs where maximum output is desirable, minimum tolerance of ±0. 125mm is economical on both diameter and length of turn.

在某些情况下,在连续生产过程中,只进行一次切削加工时的公差可以达到±O.05 mm。对于某些零件,槽宽的公差可以达到±O.125mm。镗孔和采用单刃刀具进行精加工时,公差可达到±O.0125mm。在希望获得最大产量的大批量生产中,进行直径和长度的车削时的最小公差值为±O.125mm是经济的。

Milling

铣削

With the exceptions of turning and drilling, milling is undoubtedly the most widely used method of removing metal. Well suited and readily adapted to the economical production of any quantity of parts, the almost unlimited versatility of the milling process merits the attention and consideration at designers seriously concerned with the manufacture of their product.

除了车削和钻削,铣削无疑是应用最广泛的金属切削方法。铣削非常适合于而且也易于应用在任何数量的零件的经济生产中。在产品制造过程中,许许多多种类的铣削加工是值得设计人员认真考虑和选择的。

As in any other process, parts that have to be milled should be designed with economical tolerances that can be achieved in production milling. If the part is designed with tolerances finer than necessary, additional operations will have to be added to achieve these tolerances and this will increase the cost of the part.

与其他种类的加工一样,对于进行铣削加工的零件,其公差应该被设计成铣削生产所能达到的经济公差。如果零件的公差设计得比需要的要小,就需要增加额外的工序,以保证获得这些公差——这将增加零件的成本。

Grinding

磨削

Grinding is one of the most widely used methods of finishing parts to extremely close tolerances and low surface roughness. Currently, there are grinders for almost every type of grinding operation. Particular design features of a part dictate to a large degree the type of grinding machine required. Where processing costs are excessive, parts redesigned to utilize a less expensive, higher output grinding method may be well worthwhile. For example, wherever possible the production economy of centerless grinding should be taken advantage of by proper design consideration.

磨削是一种应用最广泛的零件精加工方法,用来获得非常小的公差和非常低的表面粗糙度。目前,几乎存在着适合于各种磨削工序的磨床。零件的设计特征在很大程度上决定了需要采用的磨床的种类。当加工成本太高时,就值得对零件进行重新设计,使其能够通过采用既便宜又具有高生产率的磨削方法加工出来。例如,在有可能的时候,可以通过对零件的适当设计,尽量用无心磨削加工,以获取经济效益。

Although grinding is usually considered a finishing operation, it is often employed as a complete machining process on work which can be ground down from rough condition without being turned or otherwise machined. Thus many types of forgings and other parts are finished completely with the grinding wheel at appreciable savings of time and expense.

尽管通常认为磨削适用于精加工工序,对那些适合于采用磨削来完成粗、精加工工序的工件,也经常采用磨削方法完成全部加工工作,而不采用车削或者其他加工方法。因此,许多种类的锻件和其他零件,可以采用磨削的方法完成其从毛坯到成品的全部加工,这可以显著地节约时间和费用。

Classes of grinding machines include the following: cylindrical grinders, centerless grinders, internal grinders, surface grinders, and tool and cutter grinders.

磨床有以下几种类型:外圆磨床、无心磨床、内圆磨床、平面磨床和工具磨床。

The cylindrical and centerless grinders are for straight cylindrical or taper work; thus splines, shafts, and similar parts are ground on cylindrical machines either of the common-center type or the centerless machine.

外圆磨床和无心磨床是用来磨削圆柱形工件或者圆锥形工件的。因此,花键轴、轴和其他类似的零件是采用普通的外圆磨床,或者采用无心磨床进行加工的。

Thread grinders are used for grinding precision threads for thread gages, and threads on precision parts where the concentricity between the diameter of the shaft and the pitch diameter of the thread must be held to close tolerances.

螺纹磨床用来磨削螺纹量规上的精密螺纹和用来磨削螺纹的中径与轴的同心度公差很小的精密零件上的螺纹。

The internal grinders are used for grinding of precision holes, cylinder bores, and similar operations where bores of all kinds are to be finished.

内圆磨床用来磨削精密的孔、汽缸孔以及各种类似的,需要进行精加工的孔。

The surface grinders are for finishing all kinds of fiat work, or work with plain surfaces which may be operated upon either by the edge of a wheel or by the face of a grinding wheel. These machines may have reciprocating or rotating tables.

平面磨床用来对各种平面工件,或者带有平面的工件进行精加工。可以采用砂轮的边或者砂轮的端面进行磨削。这类机床上装有往复式工作台或者回转式

工作台。

微信

QQ1:3097331788 QQ2:2601997959 QQ3:2993773635