微型燃气机压缩机叶片的设计

摘 要

当今世界,风力发电已成为新能源主题之一。与此同时,风力发电机叶片的发展也十分迅速。其良好的设计、可靠的质量和优越的性能是保证风力发电机组正常稳定运行的决定因素。叶片的翼型设计、结构形式直接影响风力发电装置的性能和功率。叶片是风力发电机中最核心的部分,是风力发电机中叶轮的最基础和最关键的部件,所以叶片设计的好坏,决定了风力发电机的优劣。叶片也是受力最为复杂的部件。设计良好的叶片是风力机获得较高风能利用系数和较大经济效益的基础。叶片作为接收风能的主要部件,在整个风电设备系统中的地位尤显重要,要求其具有合理的翼型设计。优质的材料和先进的工艺,其设计!制造和性能成为了重点研究和大力发展的目标"目前对于叶片的研究集中在翼型、结构、材料和工艺制造方面.

关键词

微型燃气机,压缩机,叶片,尺寸,强度,应力,叶片数,工艺流程,制作流程,注意点,outcad,国内外著名制造商,叶片与压缩机关系。

英文翻译

In today's world,wind power has become one of the.new energy。 theme. At the same time, the development of wind turbine blade is also very quickly. The good design, reliable quality and superior performance is to ensure that the determinants of the normal and stable operation of wind turbines. Airfoil design, blade structure directly affect the performance and power of wind power generation device. The blade is the core part of the wind generator, is the most basic impeller in wind power generator and the most critical components, so the blade design is good or bad, the wind turbine performance. The leaf is the most complex part. Blade design is a good wind turbine foundation for high wind energy utilization coefficient and greater economic benefits. Leaves as receiving the main components of the wind energy in the entire wind power equipment system is particularly important, a reasonable airfoil design! Quality materials and advanced technology, designed manufacturing and performance become the focus of research and vigorously development for blade research focused on the airfoil! structure! materials and manufacturing process.Gas engine compression engine vane size intensity stress number of leavesProcess flow manufacturing process lime light famous manufacturers at home and

Abroad relationship between blade and compressor

目录

第一章 微型燃气机及其压缩机叶片的概述·····································1

1.1微型燃气机的基本介绍················································1

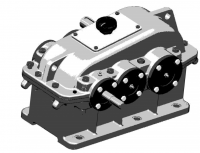

1.2压缩机的介绍························································2

1.3叶片的介绍··························································3

第二章 总体方案设计·····················································5

2.1设计要求·····························································5

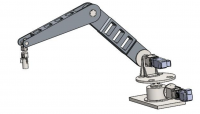

2.2结构设计方案························································5

2.3叶根选型·····································································5

第三章 叶片结构设计及计算················································8

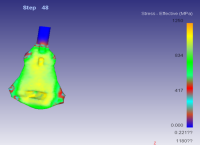

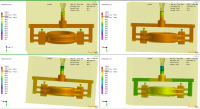

3.1气动载荷····································································8

3.2重力载荷····································································9

3.3离心力载荷·································································10

3.4使用载荷和设计载荷以及与安全系数的关系·································11

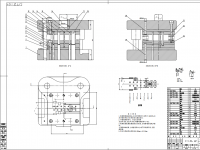

3.5叶片剖面结构形式设计·····················································12

3.6叶片铺层设计·······························································13

3.7铺层设计原则·······························································13

3.8铺层设计过程·······························································15

3.9叶片结构形式确定计算·························································16

第四章 加工材料规格要求介绍··············································19

4.1制造································································19

4.2性能及认证··························································20

4.3性能及认证··························································22

4.4识别标志····························································23

4.5文件································································23

4.6工艺资质认证························································24

第五章 工艺以及加工流程细节··············································26

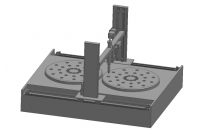

5.1加工工艺流程介绍···························································26

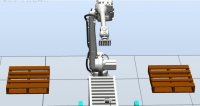

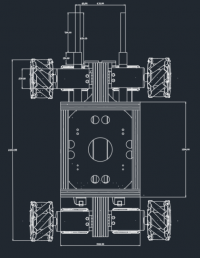

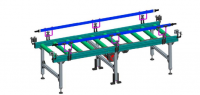

5.2部分工具以及图片···························································34

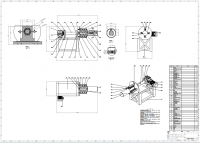

第六章 图纸·····························································37

6.1图纸的介绍··································································37

第七章 总结·····························································38

第一章 微型燃气机及其压缩机叶片的概述

1.1微型燃气机的基本介绍

微型燃气轮机(Microturbine或Micro一turbines)这是一种近代新发展起来的微型热动机,其单个的功率范围为25~300 kW,他的技术特点是采用螺旋式叶片机械(透平叶片和离心式压气机)以及热动力循环。先进微型燃气轮机具有多台小机器集成而扩大容量、多种燃料的选择、燃料利用率高、低污染 噪音污染小、排放量低、震动量小、故障率低、可以远程控制和自动诊断故障等一系列先进技术特征。自从世界上第一次热启动成功以后,目前,我国国内已经成功在中国航空安装了一台功率已经达到了1000kw的燃气机轮机,并且已经达到了预定的运行状态,运行状态目前非常稳定,这标志着千瓦级的微型燃气机在中国有着标志性的进步, 目前美国和日本都有多家企业在积极开发制造相应的设备。日本的多家企业,如东京电力、丰田汽车、三菱重工、出光兴产、东京瓦斯和大阪瓦斯等公司,都在使用美国卡普斯顿公司的技术开发热电并用型系统。为了促进该技术的发展更加迅速, 日本方面已经计划在明年春减小对小型自用发电业的限制。以便促进它的发展。目前,在中科学技术部“863”项目支持下,由中国科学院工程热物理研究所、哈尔滨东安集团、西安交通大学三家单位组成的合作伙伴已经完成了对100KW级微型燃气轮机机制造,并通过了世界级组织的验收,预计在不久的将来会很快推出市场与大家见面。

目前国内压缩机供应不足的情况下非常严重,为了缓解国内的需求压力过大中国还需大量的进口压缩机。主要的进口国家是德国、美国、意大利、日本、丹麦、巴西、韩国等。但是近年来,国内压缩机厂家通过技术引进和设备改造,国产压缩机的质量、产量都大幅度提高,相信在不久的将来,中国便可以自给自足,甚至可以出口其他国家。

我对中国将来会对這方面发展好非常有信心,原因如下:第一:制造业已经成为中国经济的重要支柱。第二:中国的制造业今天在世界上已经占有很重要的位置,相信在未来几年,中国制造会稳居世界第一,对此我非常有信心。第三:优化升级,走向制造尖端,做高档产品,这必将是中国制造未来发展的主要目标。我认为中国制造业将来会面临几大大转变:一:拉动投资,提高技术,提高质量,改变劳动力素质的转变;二:重注重产量到注重技术和质量的积累的转变;三:从生产型制造向制造型服务转变;四:从制造业的低利润处走向制造业的高利润处的转变;五:对外界经济压力适应能力变好的转变。第五:健康制造、高端科技制造、有机型制造将成为中国制造业将来的发展方向。健康制造就是在我们制造业的产品的全过程中,从设计理念、再到生产到制造的全部环节,都要始终拥有绿色环保的理念。例如开发节约能源的产品、节约能源的技术、节约能源的工艺;发展少污染、甚至是没有污染、低碳排放的产品和工艺流程;促进低碳发展、有效的促进循环经济;减少资源和能源的消耗、节约可以省下的资源;保护生态环境是极其重要的。

参考文献

[1] 龙泽强.风力发电.21世纪的绿色能源.世界科技研究与发展[M],2001.23(4):32-34

[2] 李俊峰. 风力12在中国,化学工业出版社[M],2005.1-4

[3] 陈博. 国际风能设备展巡礼[J]. 中国玻璃钢协会主办,2006.130(4):13-19

[4] 董永棋. 国外风力发电机FRP叶片的近况[J].纤维复合材料,2001.9(3):46-49

[5] 赵稼祥. 复合材料在风力发电上的应用[M]. 高科技纤维与应用,2003,28(4):1-4

[6] 李泽田,尤德宽. 风力发电一一复合材料的一个重要应用领域[M].航天技术与民品,1997.2:35~36

[7] 苏绍禹. 风力发电机设计与运行维护[M]. 北京:中国电力出版社,2003.77-84

[8] 风电相关消息:风力发电机叶片市场分析[J]

[9] 叶杭冶. 风力发电机组的控制技术.[M] 北京:机械工业出版社,2003.14-16

[10] 倪受元. 风力发电讲座:第一讲风力机的类型与结构.[J] 太阳能,2000

[11] 倪受元. 风力发电讲座:第二讲风力机的工作原理和气动力特性[J]. 太阳能,2000

[12] 范波涛,李绍珍,苑国强. 风机叶片的几何形状研究[M].山东工业大学学报,2001,2

[13] 陈雷,邢作霞.风力机叶片形状设计[M]. 农村能源.1999.22(4):22-23

[14] 陈家权,杨新彦.风力机立体图的设计[M]. 机电工程.2006.23(4):37~39

[15] 林清安. Pro/Engineerwildfire2.0零件设计[]M.北京:清华大学出版社,2005

[16] 杨乃宾,章怡宁. 复合材料飞机结构设计[M].北京:航空工业出版社,2002

[17] 刘雄亚,晏石林. 复合材料制品设计及应用[M].北京:化学工业出版社,2003.256-275

[18] 李顺林,王兴业. 复合材料结构设计基础[M].武汉:武汉理工大学出版社,1993.200-208

[19] 张少实,庄茁. 复合材料与弹性力学[M].北京:机械工业出版社,2005.116-123

[20] 王耀先. 复合材料结构设计[M].北京:化学工业出版社,2001.238-2477