无轴承无刷直流电机结构设计 摘要:

目前研究的无轴承电机均是将电机和转子悬浮磁路合为一体,两个磁场的叠加一方面容易造成磁饱和,使电机的承载能力下降,影响电机的稳定悬浮;另一方面电磁转矩与径向悬浮力之间具有很强的非线性耦合,而实现解耦控制是非常复杂的。将无刷直流电机的优点与磁悬浮轴承的优点结合,提出一种六自由度可控的无轴承无刷直流电动机结构,通过研究其悬浮原理和运行原理,建立了转子偏心时的精确数学模型和PWM(脉宽调制)调速的精确数学模型,经仿真测试,表明了这种电机结构的合理性。主要特点是承载能力高且电磁转矩控制与径向悬浮力的控制相互独立,无需复杂的非线性解耦控制。

关键词:无轴承无刷直流电机;结构;模型;六个自由度可控;PWM

目录

摘 要·····························································3

Abstract····························································3

绪论························································4

1.1 无刷直流电机的研究意义和概况···································4

1.2 电机控制系统现状和发展········································6

1.3 无位置传感器检测技术概述·······································7

1.4 论文的提出及内容的安排········································9

第二章 无轴承无刷直流电机的结构设计及原理··························9

2.1 引言··························································9

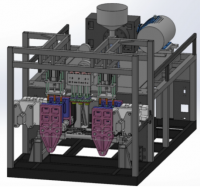

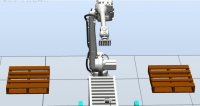

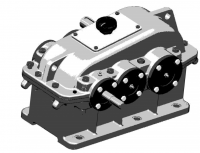

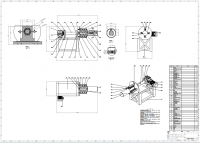

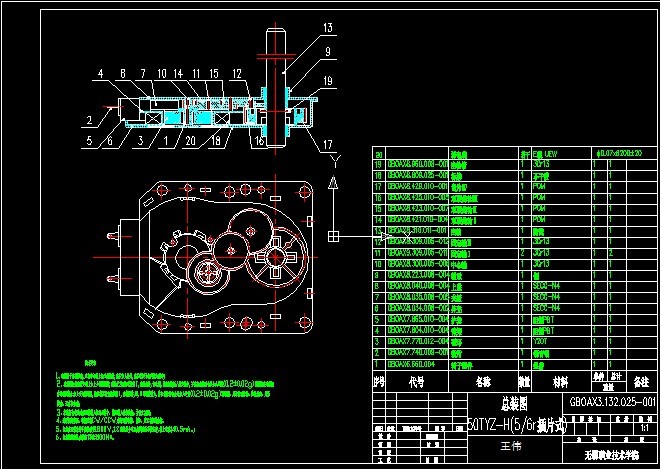

2.2 无轴承无刷直流电机的组成及原理································10

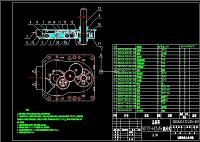

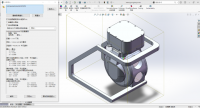

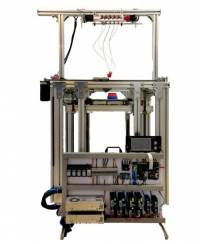

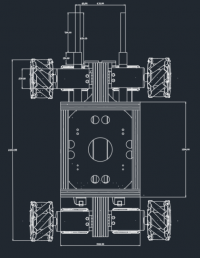

2.3 无轴承无刷直流电机的总体结构设计······························18

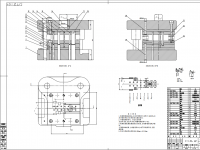

2.4 无轴承无刷直流电机的主要零部件的结构设计······················19

第三章 磁悬浮轴承的工作原理及数学建模····························24

3.1 引言··························································24

3.2 无轴承无刷直流电机的悬浮原理··································25

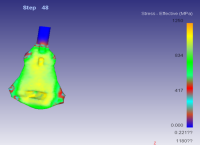

3.3 数学模型······················································26

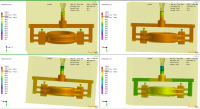

3.4 控制系统仿真分析··············································29

3.5 小结··························································30

第四章 结论与展望················································31

参 考 文 献·······················································31

致 谢 ···························································33

参 考 文 献

[1] 戈素贞.“新型无轴承无刷直流电动机结构与模型研究”.《农业工程学报》,2008年02月 第24卷第2期:131-135.

[2] 谢宝昌、任永德等.《电机的DSP控制技术及其应用》.北京:北京航空航天大学出版社.

[3] 孙建忠、白凤仙等.《特种电机及其控制》.北京:中国水利水电出版社.

[4] 陈世坤 《电机设计》.北京:机械工业出版社.

[5] 黄国治、傅丰礼等.《中小型旋转电机设计手册》.北京:中国电力出版社.

[6] 朱熀秋、邓智泉、袁寿其、李冰等,“永磁偏置径向-轴向磁悬浮轴承工作原理和参数设计”《中国电机工程学报》,2002年9月,第22卷第9期.

[7] 陈峻峰 编著.《永磁电机》上、下册.北京:机械工业出版社.

[8] 王凤翔、王继强、孔志国.“具有被动式磁力轴承的无刷直流电机研究”.中国电机工程学报.2004年第24卷第5期:90-95.

[9] 邓智泉、仇志坚、王晓琳等.“无轴承永磁同步电机的转子磁场定向控制研究” .《中国电机工程学报》,2005年第25卷第1期:104-108.