数控刀具与自动线刀具的应用分析

Abstract: Analysis of a number of modern machine tool dynamic holographic characteristics of tools, combined with the quality of our tools come caste items made with the tools to test specific reports.

【摘要】:分析了数近代机床工具全息动化工具的特点,并结合我国工具质量物品种性得出了工具造用至测试具体报导。

Key words: tool; the number of empty machine tool; automated production tool;

【关键词】:刀具;数空机床;自动生产工具

In recent years, the NC machine tools (CNC), machining center (MC), Flexible Manufacturing Cell (FMC) and flexible manufacturing (FMS) has been growing a wide range of applications, so that machinery manufacturers have undergone tremendous changes. Processing system as an important component of automated cutting tool design and the rational use of the right of the machine and automatic line of work, improve productivity and processing quality are of great significance.

近年来,数控机床(CNC)、加工中心(MC)、柔性制造单元(FMC)和柔性制造(FMS)得到日益广泛的应用,使机械制造面貌发生了很大变化。作为加工系统的一个重要组成部分,自动化加工用刀具的正确设计与合理使用,对机床及自动线的正常工作、提高生产效率及加工质量均具有重要意义。

1 CNC tool cutter and automatic line characteristics

1数控刀具与自动线刀具的特点

CNC tool and automatic wire cutter and general machine tools used in cutting tools has been no significant real distinction, but in order to enable CNC machine tools and automatic lines to normal operation, they should have the following characteristics:

数控刀具及自动线刀具与普通机床上用的刀具实际没有多大区别,但为了使数控机床和自动线能正常运转,它们需具有以下特点:

⑴ tool cutting performance must be stable and reliable high

⑴ 刀具的切削性能必须稳定可靠高

At present, the production of tool life is usually used to evaluate the tool is good or bad. The greater the tool life, better express tool cutting performance. But cutting the same number of parts, as a result of the use of the tool material and workpiece material can not be exactly the same, together with the grinding quality can not strictly control the number of factors, so even under the same conditions, tool life is still random changes. Therefore, CNC and automatic online, in addition should give the average tool life indicators should give a reliable indicator of tool Tp. It has become a key tool to choose targets. Reliability are usually the provisions of P ≥ 0.9 or 9% when the tool cutting time T0.9. Research shows that when durability close to normal distribution of random variables, such as durability in the average T as a standard tool of the reliability of only 50%.

目前生产上通常用刀具耐用度来评定刀具的好坏。刀具耐用度愈大,表示刀具切削性能愈好。但是切削一批相同的零件,由于使用的刀具材料及工件材质不可能完全相同,再加上刃磨质量等一些不能完全严格控制的因素,所以即使在相同条件下刀具耐用度仍随机变动。因此在数控和自动线上,除应给出刀具耐用度的平均值指标外,还应给出刀具的可靠指标Tp。它已成为选择刀具的关键性指标。通常是规定可靠度P≥0.9即9%时刀具切削时间T0.9。研究表明,当耐用度的随机变量接近于正态分布时,如以耐用度的平均值T作为标准,刀具的可靠性只有50%。

⑵ size high durability

⑵ 高的尺寸耐用度

Requirements of the size of cutting tool has a high durability so that the tool can be adjusted in a process more in line with the dimensional accuracy of parts.

要求刀具有高的尺寸耐用度,以使刀具在一次调整后能加工出较多符合尺寸精度的零件。

⑶ reliable chip-breaker

⑶ 可靠地断屑、排屑

Chip Tool must be able to reliably breaking or cutting or volume control cuttings. CNC machine tools and automatic lines for each machine on-site equipment. Device with many knives, cutting a large amount of swarf many, therefore, plastic metal cutting, it is important to control the chip is not entangled in the cutting tool, workpiece and process equipment, without prejudice to the work of automatic line cycle, the control chip is not flying, to ensure operator safety not affect the cutting fluid injection does not affect the positioning of parts and distribution, do not scratch the surface has been processed, so that chips can be cleaned easily and, to that end, the use of volume chip or chip-breaker block cutter, or cutting or vibration cutting gap measures improve chip breaking effects.

刀具必须能可靠地断屑或卷屑即切削控制。数控机床和自动线机床上每一工位设备上。装置着许多刀具,切削量大,切屑多,因此,在切削塑性金属时,必须控制切屑不缠绕在刀具,工件及工艺装备上,不妨碍自动线的工作循环,控制切屑不飞溅,保证操作者安全,不影响切削液喷注,不影响零件的定位和输送,不划伤已加工表面,使切屑易于清理,为此,采用卷屑槽或断屑块的刀具,或用间隙切削或振动切削措施提高断屑效果。

⑷ should have high accuracy

⑷ 应具有高的精度

Cutting part of the geometry changes to a small, knife body and blade holders repeated loading and unloading should also be able to maintain the accuracy and stability. For example, turning the blade tools in general have more than M-class general-purpose precision machine tool commonly used general-level D-class - so loaded knife knife body machining accuracy should also improve. Therefore, now abroad with no pre-set the refinement tool.

刀具切削部分的几何尺寸变化要小,刀体刀杆和刀片反复装卸也应能保持精度稳定。例如,可转位车刀上的刀片一般要有M级以上精度通用机床常用普通级D级--这样装刀的刀体加工精度也应提高。因此,国外现在已用不需预调的精化刀具。

⑸ rapid replacement and pre-set size

⑸ 快速更换及尺寸预调

Tool should be able to fast or automatic replacement, and the need to have control and adjust the size of the function or the automatic tool wear compensation device to reduce ATC adjustment downtime.

刀具应能快速或自动更换,并需有控制和调整尺寸的功能或具有刀具磨损的自动补偿装置,以减少换刀调整的停机时间。

⑹ have tool wear and breakage of the line monitoring system

⑹ 有刀具磨损和破损的在线监测系统

Should have the tool breakage prediction and alarm device. In order to prevent sudden tool breakage, cutting tools in the hole and tap on standing has overload protection device.

应具有刀具破损预测与报警装置。为防止刀具突然破损,在孔加工刀具和丝锥上常备有过载保护装置。

⑺ tool to achieve standardization, serialization, generic, and in order to do scheduling processes and tool management.

⑺ 要实现刀具的标准化,系列化,通用化,以利干编排加工程序和刀具的管理。

2 and choose the type of tool

2刀具的类型及选用

CNC tool and cutter automatic wire cutter can be divided into standard and special cutting tool two broad categories. Processing in order to improve the adaptability. CNC machine tools and taking into account the limited storage capacity, so these machines should be to minimize the use of special tools, the choice of standard criteria for the tool or tool combinations. CNC machine tools and automatic online tool commonly used have, turning tools, high-speed steel twist drill, flat drill machine folder, reaming drill, reamer, boring cutter, cutter, face milling cutter, Taps and a variety of complex tool.

数控刀具与自动线刀具可分为标准刀具和专用刀具两大类。为了提高加工的适应性。同时考虑到数控机床库容量有限,所以在这些机床上应尽量减少使用专用刀具,而选用通用标准的刀具或刀具标准组合体。数控机床和自动线上常用的刀具有,可转位车刀,高速钢麻花钻,机夹扁钻,扩孔钻,铰刀,镗刀,立铣刀,面铣刀,丝锥和各种复合刀具等。

Selection tool and its use conditions, material type and size of chip-breaker and the cutting tool and blade production supply and many other factors. Such as the choice of appropriate tools not only offer to play its due efficiency, while at the same time improve the processing quality, reduce production costs. Moreover, the structure of the form of cutting tool technology sometimes programming also plays a decisive influence, so to be taken seriously, considering. General selection principles are as follows:

刀具的选用与其使用条件,式件材料和尺寸,断屑及刀具和刀片的生产供应等许多因素有关。如选用适当不但能使机床发挥出应有的效率,同时能提高加工质量,降低生产成本。而且,刀具的结构形式有时对工艺方案的拟定也起着决定性影响,因此必须慎重对待,综合考虑。一般选择原则如下:

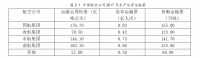

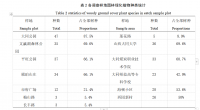

⑴ tool in order to improve the durability and reliability. Should try to choose a variety of high-performance, high efficiency, long life of cutting tools made of tool material, the use of superhard materials such as synthetic polycrystalline diamond, diamond anvil blade layer, cubic boron nitride cNB, cNB carbide composite films and so on, high-performance composite ceramics, coated cutting tools, carbide blade is a laminated abrasion resistance, strength and impact toughness, such as better overall performance carbide blade, it is better in ductile alloys based on YG8 , and then press a layer of thickness 0.2 ~ 0.5mm containing rare metals such as Tic and Tac carbide blade and a variety of super-hard high-speed steel. Must be pointed out that based on the current situation of China's anti-reality, and some new type of blade is still in its trial phase of the transition, performance not stable enough, so general-purpose high-speed steel and carbide W18Cr4V and W6M05Cr4V2 remains our manufacturing CNC tool cutter and automatic line the main materials, but coating should be selected grades. And prior to use blades to go through rigorous testing in order to avoid damage caused by a tool downtime, and even the whole line should not work automatically.

Should be selected folder

⑴ 为了提高刀具的耐用度和可靠性。应尽量选用各种高性能,高效率,长寿命的刀具材料制成的刀具,如使用各种超硬材料人造聚晶金刚石,金刚石压层刀片,立方氮化硼cNB,cNB硬质合金复合片等,高性能复合陶瓷,涂层刀具,硬质合金层压刀片是一种耐磨性,强度及冲击韧性等综合性能较好的硬质合金刀片,它是在韧性较好的YG8合金基础上,再压一层厚度为0.2~0.5mm含Tic和Tac等稀有金属碳化物的刀片和各种超硬高速钢等。必须指出,基于目前我国现实防情况,有些新型刀片还处于过渡试制阶段,性能不够稳定,所以通用型高速钢w18Cr4V和W6M05Cr4V2与硬质合金仍是我国制造数控刀具与自动线刀具的主要材料,但应尽量选用涂层牌号。而且使用之前刀片须经过严格检验,以避免一把刀具损坏而造成停机,甚至使整条自动线不能工作。

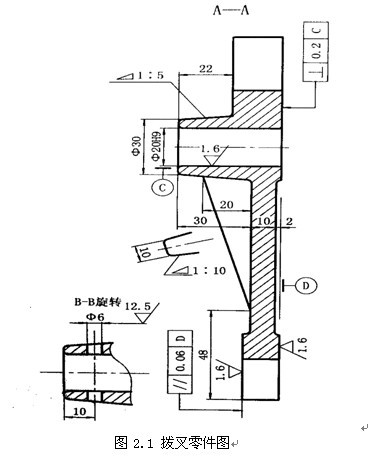

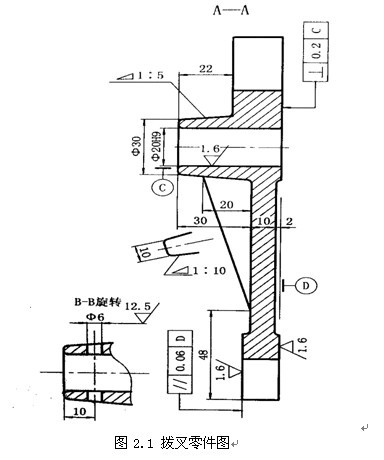

⑵ turning machine tool structure. Turning the existing tools of national standards GB5343 - 85 in the provisions of the cutter varieties, their location accuracy requirements of the lower tip to the side of tip base and tip height of Tolerance Tolerance is a O.33-0.39 mm, tip to the base after one Tolerance for 2.5-2.9mm, therefore, only apply to ordinary lathe and with a quick tool change CNC Lathe folder. This is because the tool tip on the location of the manufacturing error is too large and can be quick tool change and tool folders together in the plane when the pre-set compensation. Requirements such as tool use without a pre-set such as the use of disc-shaped or cone-shaped turret, you should choose Precision Turning Turning the Corner location precision can reach ± 0.08mmX direction and Y direction, ATC After shear test Compensation amended to meet the general increase in the next turning accuracy. As the band Shen-hole and posterior horn of the cutter blade structure is simple, usually just with a head screws directly to the blade 3 can be pressed on in the Tool Bar. It has less clamping components, manufacturing, chip-breaker to facilitate reliable, Segment part of their small size, no protrusion of the knife head, chip unimpeded outflow, etc., and should therefore give priority to the use, it can be widely used in the manufacture of a variety of small size Cylindrical turning tool and the end of the lathe tool, hole boring and boring cutter head knife, turning the bit, called transposition of three face milling cutter and the cutter and so on.

⑵ 应选用机夹可转位刀具的结构。现行的可转位车刀国家标准GB5343--85中的规定的刀具品种,因其刀尖位置精度要求较低刀尖到侧基面允差和刀尖高度允差为一O.33-0.39mm,刀尖到后基面允差为一2.5-2.9mm,因此只适用于普通车床及带有快换刀夹的数控车床。这是因为刀具上刀尖位置过大的制造误差,可通过快换刀夹和刀具一起在机外预调时得到补偿。如要求刀具不经过预调使用如使用圆盘形或圆锥形刀架,则应选用精密级可转位车刀的刀尖位置精度可达±0.08mmX方向和Y方向,换刀后经过试切补偿修正,可满足一般车削加下精度的要求。由于带沉孔和后角刀片的刀具结构简单,通常只需用一个沉头螺钉就可直接将刀片3压紧在车刀刀杆上。它具有夹紧元件少,制造方便断屑可靠,刀头部分尺寸小,刀头上无凸出部分,切屑流出不受阻碍等优点,因此应优先采用,这可广泛用于制造各种小尺寸的外圆车刀和端面车刀、内孔镗刀和镗刀头、可转位钻头、叫转位铣刀和三面铣刀等刀具上。

⑶ in order to focus on processes, improve productivity and guarantee the processing precision, should maximize the use of composite cutting tool. Among them, compound Drilling Tool use is most common.

⑶ 为了集中工序,提高生产率及保证加工精度,应尽可能采用复合刀具。其中以孔加工复合刀具的使用最为普遍。

⑷ finishing holes can be boring or Reaming process. Because BORING simple structure, convenience of grinding and adjust, so as long as the boring bar of rigid enough under the conditions should be used BORING. In particular, are greater than 80cm in diameter of the hole, the hole is too small should not use BORING processing, otherwise boring bar as a result of too small will cause vibration and the impact of machining accuracy and surface roughness.

⑷ 精加工孔时可采用镗孔或铰孔工艺。由于镗刀结构简单,刃磨和调整方便,因此只要在镗杆刚性足够的条件下,应尽量采用镗刀。尤其是孔径在大于80cm的孔,过小的孔不宜用镗刀加工,不然由于镗杆过细,会引起振动而影响加工精度和表面粗糙度。

Should try to adopt a variety of high-performance tool. Such as high-rigid drill, drill drill extended four-blade, single blade reamer carbide, precision fine-tuning BORING, waveform edge cutter and cutting tools, such as heat pipe. 3 Several highly efficient CNC machine tool

应尽量采用各种高效刀具。如高刚性麻花钻,钻扩四刃钻,硬质合金单刃铰刀,精密微调镗刀,波形刃立铣刀和热管式刀具等。3几种高效率数控自动线刀具

In CNC machine tools and automatic lines, to improve the drill durability and productivity, foreign large-scale use of highly rigid twist drill. This bit in the following characteristics:

在数控机床和自动线上,为提高钻头耐用度和生产率,国外大量使用高刚性麻花钻。这种钻头在如下特点:

Helix angle, and can be increased to 35. 1 45. In order to reduce the cutting force.

螺旋角大,可增大到35。一45。以降低切削力。

Thick core thickness. Could be core drilled by a standard thickness of 0.125-0.15D to 0.3D, D for diameter drill to improve strength and rigidity of the drill bit.

钻芯厚度厚。可将钻芯厚度由标准钻的0.125-0.15D提高到0.3D,D为钻头直径,以提高钻头的强度与刚性。

Allow the introduction of a new chip shape. The rigidity of drill cuttings and tolerance are two contradictory problems, such as by increasing the thickness of coring method to improve the rigidity of the section capacity is necessary to reduce litter, it would be difficult Chip. Therefore, we must allow the introduction of a new chip shape.

采用新的容屑槽形状。钻头的刚性与容屑是两个相互矛盾的问题,如用增加钻芯厚度的方法来提高刚性,容屑的断面就要减小,这样会使排屑困难。所以必须采用新的容屑槽形状。

Because Reaming a better guarantee than the boring drill hole location and shape accuracy. Therefore, CNC machine tools and automatic online the extensive use of fine-tuning and set-size can be installed in a variety of blade head Boring Bar.

由于铰孔比镗钻孔更能保证孔的位置和形状精度。所以数控机床和自动线上广泛使用尺寸可微调和镶装刃头的各种镗刀杆。

References:

参考文献:

[1] WU Dao Quan, Metal Cutting Principle and Tool, Chongqing University Press, 1999.11

[1] 吴道全,金属切削原理及刀具,重庆大学出版社,1999.11

[2] Yung-Tai Chen, machinery manufacturing technology practice, Machinery Industry Press, 2003.1

[2] 陈永泰,机械制造技术实践,机械工业出版社,2003.1

[3] Shanghai Vocational and Technical Education Curriculum Reform and Textbook Development Unit, machining technology and equipment, Mechanical Industry Press, 2006.1

[3]上海市职业技术教育课程改革与教材建设委员会组编 ,机械加工工艺及装备,机械工业出版社 ,2006.1

[4] Li Cheng, mold manufacturing technology, Mechanical Industry Press, 2004.7

[4] 李云程,模具制造工艺学, 机械工业出版社,2004.7