货车万向节传动轴设计

摘要:机电一体化专业的毕业设计,对于我们来讲是一次重要的实践过程。

通过自己动手查阅资料,咨询导师等途径,使自己能够将所学到的知识融会贯通。了解设计的过程,通过自己的实践。强化记忆曲线。在我们步入社会之前学会综合应用的技能。

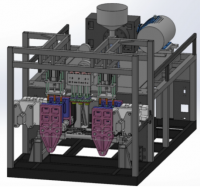

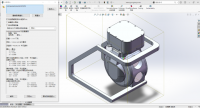

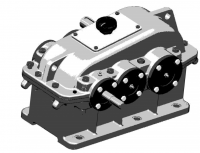

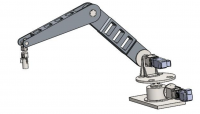

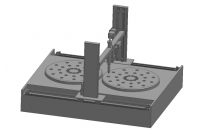

本次我是设计货车万向节传动轴。首先对给定任务加以分析;对总体方案加以论证。前期参考各种文献资料,对课题做更进一步的了解。而后确定万向传动轴的型号。分析所选万向节和传动轴,计算各设计零部件的运动和动力参数,如各轴的受力、转矩、转速、功率;计算载荷,强度校核。运用CAD和PROE软件绘制二维图和三维图。整理和编写设计说明书。设计步骤:1.万向传动轴概述、2.万向节结构方案设计、3.万向传动的运动分析4.万向节设计、5.传动轴结构分析和设计、6.中间支承结构分析与设计、7整理说明书。

经过老师的指导,自己的刻苦努力,能够按照要求完成毕业设计的任务,并且完善自己的知识体系。希望自己设计的成果在工厂生产实践中起到作用。在整个毕业设计过程的时间内,提高身独立思考的能力,这对于我们即将迈出校门的应届毕业生来说,将是一个无价的财富。为自己的大学生活缔造美好结局

关键词:万向节;动力参数;传动轴;中间支撑结构分析。

Van cardan shaft design

Abstract: the mechanical and electrical integration professional graduation design, is an important practice for our process.

Through your own data access, counselor, make oneself can have learned knowledge to achieve mastery through a comprehensive study. Understanding of the design process, through their own practice. Strengthen the memory curve. Before we enter society institute comprehensive application skills.

This design I am van cardan shaft. First of all, for a given task analysis; The overall plan to argue. Early refer to all kinds of literature, understanding of the subject further. And then determine the universal transmission shaft model. Analysis of the selected universal joint and transmission shaft, calculate the design movement and the dynamic parameters of the parts and components such as the axial force, torque, rotational speed, power; The load calculation, intensity. The CAD and PROE software to draw 2 d and 3 d figure. Organizing and writing the design specification. Design steps: 1. 2 summary of universal transmission shaft, universal joint structural design, (3) of the universal driving motion analysis 4. Universal design, 5. The shaft structure analysis and design, 6. The middle supporting structure analysis and design, 7 finishing instruction.

Through the guidance of the teacher, and his own hard work, be able to complete the graduation design in accordance with the requirements of task, and perfect their knowledge system. Hope their design results play a role in the production practice. In the whole process of graduation design time, improve the ability of independent thinking, this, for we are going to a school's graduates will be a priceless wealth. Create a happy ending for his university life

Key words: universal joint, dynamic parameters, transmission shaft, intermediate support structure analysis.

目 录

摘要 1

Abstract 2

目录 3

1 车型选择及相关参数 5

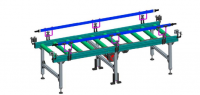

1.1车型图片 5

1.2车型参数 .5

2 万向传动方案选择 6

2.1 万向传动轴的概述 6

2.2 万向节选择 6

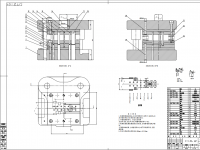

2.3 中间支承 9

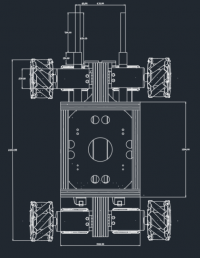

2.4传动轴结构 11

3 万向传动轴的设计计算 12

3.1 万向传动轴1设计 12

3.1.1 传动轴载荷计算 12

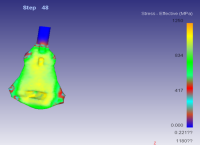

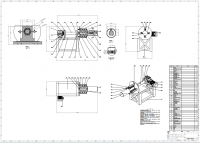

3.1.2 十字轴万向节设计 13

3.1.3传动轴结构分析与设计 17

3.1.4传动轴的强度校核 19

3.1.5花键轴和花键的设计和校核 19

3.2传动轴2的相关计算 21

3.2.1传动轴载荷计算 21

3.2.2十字轴万向节设计 21

3.2.3传动轴结构设计与转速校核 21

3.2.4传动轴的强度校核 21

3.2.5花键轴和花键的设计和校核 22

3.2.6传动轴的花键齿侧挤压应力 22

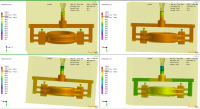

4万向传动轴相关说明图 24

结 论 26

致 谢 27

参考文献 28

参考文献

1.王望予.汽车设计【M】.北京:机械工业出版社,2004,114-134

2.机械设计手册编委会.连接与紧固【M】.北京:机械工业出版社,2007

3.机械设计手册编委会.滚动轴承【M】.北京:机械工业出版社,2007

4.刘平安 张延伟,AutoCAD 2008机械设计实例【M】.北京:机械工业出版社,2008

5.羊拯民.传动轴和万向节【M】.北京:人民交通出版社,1986

6.机械设计手册【M】.北京:化学工业出版社,1987

7 刘涛 .汽车设计,北京大学出版社,2008

8 过学迅 主编.汽车设计,人民交通出版社,2003

9 王望予.汽车设计,吉林工业出版社,2009

http://www.bysj1.com/ http://www.bysj1.com/html/5368.html

http://www.bysj1.com/html/5168.html