球墨铸铁扭力臂铸造工艺探索与缺陷分析 摘要:本文通过对风电产品中扭力臂工作的条件以及结构的分析,并结合本厂的实际生产情况确定了扭力臂的材料、型砂种类、造型工艺以及在生产中由于设计、工艺操作的不合理性导致的铸造缺陷解决方法,制造出客户满意的产品。

关键词: 扭力臂,铸造工艺,缺陷

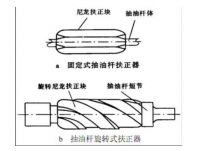

引言: 我厂是一家以生产风力发电机零部件的生产厂家,风力产品主要有轮毂,定轴,转轴,轴套,轴承座,扭力臂,底座,机体和箱体等.本文主要讲述了其中一个零部件:球墨铸铁扭力臂.此部件在风力发电机上的主要作用是防止转轴出现跑动,不稳即固定的作用,所以在使用性能上要求很高。然而在实际生产过程中由于工艺操作等诸多方面的原因难免出现如缩松,夹渣,砂泥等缺陷,所以合理的铸造工艺及正确的缺陷解决方法对于生产合格的产品就显得非常关键。 目 录

引言

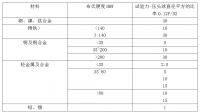

1.材料的选择················································3

2.型砂要求··················································3

2.1型砂种类的确定···········································3

2.2呋喃树脂砂的性能特点······································3

2.3 球墨铸铁扭力臂的型砂性能要求·······························4

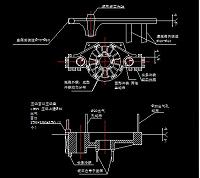

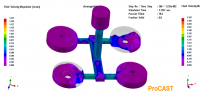

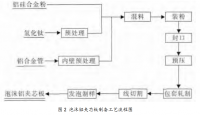

3.工艺确定·················································4

3.1造型芯方法的选择 ·········································4

3.2型芯的设计···············································4

3.3铸造工艺方案的确定········································4

3.3.1铸造分型面的选择········································5

3.3.2浇注位置的选择··········································5

3.4铸造工艺设计参数··········································5

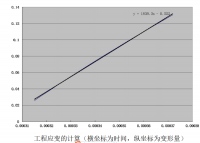

3.4.1铸造收缩率·············································5

3.4.2机械加工余量············································5

3.4.3起模斜度···············································5

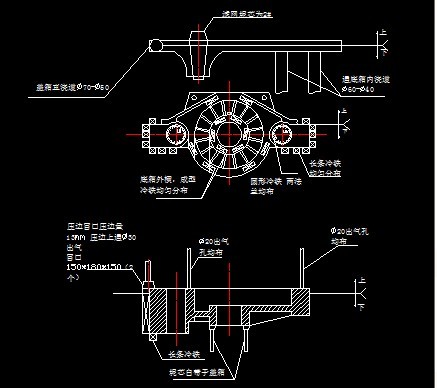

3.5浇注系统的设计············································5

3.5.1直浇道·················································6

3.5.2横浇道·················································6

3.5.3内浇道·················································6

3.5.4浇口杯·················································7

3.6冒口设计·················································7

3.6.1球墨铸铁扭力臂冒口的选择··································7

3.6.2球墨铸铁扭力臂冒口的安放位置·······························7

3.7冷铁的设计················································7

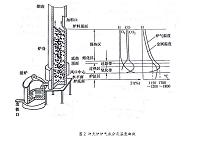

3.8球墨铸铁扭力臂的工艺说明····································8

4.铸件缺陷及其分析与解决·······································9

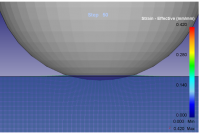

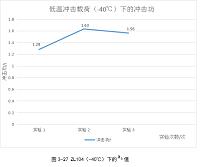

4.1缩孔,缩松的产生与解决······································9

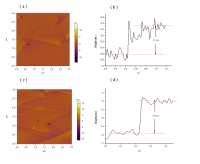

4.2铸件易出现夹渣缺陷·········································11

4.3铸件易出现砂泥缺陷·········································13

结论

参考文献表

参考文献

[1] 曹瑜强 主编 铸造工艺及设备. 机械工业出版社

[2] 李魁盛 主编 典型铸件工艺设计实例 机械工业出版社 2007

[3] 中国机械工程学会铸造分会编 铸造手册第二版 机械工业出版社

[4] 王文清 李魁盛 编 铸造工艺学 机械工业出版社 1998

[5] 浙江大学铸工教研组 砂型铸造工 艺设计 浙江大学出版社 1976

[6] 吴正华 热加工检测技术 无锡职业技术学院 2006

[7] 李弘英 赵成志 铸造工艺设计 机械工业出版社 2006

[8] 丁建生 主编 金属学与热处理 机械工业出版社 2007

[9] 李昂 吴密编 铸造工艺设计技术与生产质量控制实用手册 北京出版社 2007