基于多尺度球形探针的石墨烯摩擦特性研究

摘要

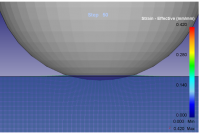

生活中的摩擦无处不在,比如说从远古时期的钻木取火,到现阶段微纳器件中所涉及的摩擦等等,大到宏观尺度,小到微观尺度。然而当器件处于微纳尺度之下时,此时的摩擦系统却不能简单地看作成宏观摩擦系统。而石墨烯作为新发现的碳材料,由于胶体探针尺寸的小型化和微型化,使其比表面积大大地増加,从而表面效应显著地增强,摩擦学问题显得尤为突出。本文利用原子力显微镜,采用锥形探针和不同曲率半径的球形探针对石墨烯表面的摩擦特性进行了相关的研究。主要研究内容如下:

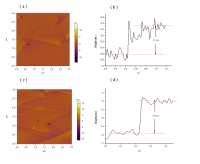

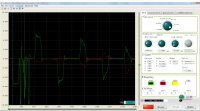

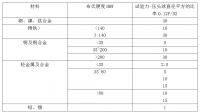

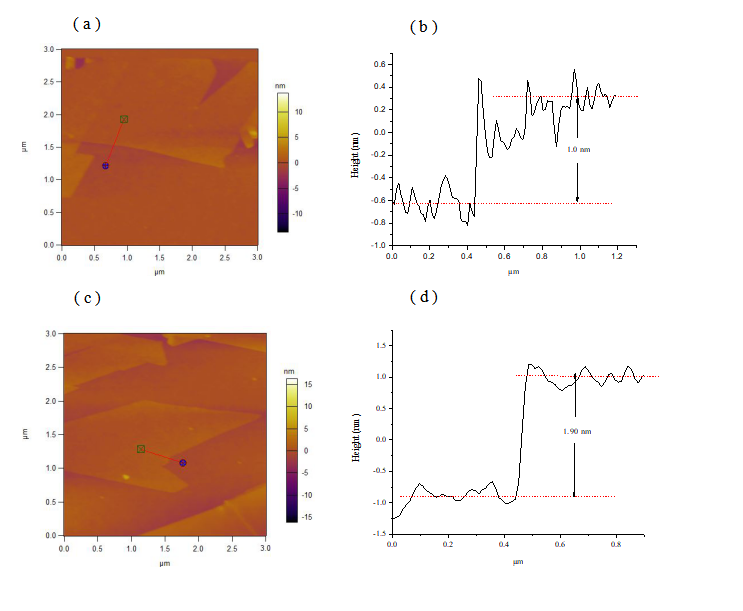

1.利用原子力显微镜,采用锥形探针和不同曲率半径的球形探针在轻敲模式下表征石墨烯的形貌,发现在轻敲模式下测得的石墨烯的厚度随探针针尖曲率半径的增大而增大。

2.利用原子力显微镜,采用锥形探针和不同曲率半径的球形探针在侧向力模式下测量其与石墨烯表面之间的摩擦力和粘附力。发现测得的石墨烯的摩擦力和粘附力均随探针针尖曲率半径的增大而增大。

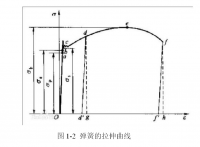

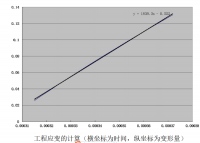

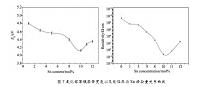

3.利用原子力显微镜,研究了法向载荷、石墨烯的厚度以及探针的滑动速度对石墨烯纳米摩擦力的影响。发现当施加-7 nN~25 nN的法向载荷时,石墨烯的摩擦力随法向载荷的增大而增大,且近似呈线性关系;当所施加的法向载荷与石墨烯的粘附力相接近时,石墨烯的摩擦力随法向载荷的增加不发生明显改变;当所施加的法向载荷与石墨烯的粘附力相差较大时,石墨烯的摩擦力随其法向载荷的增加而近似线性地增加。石墨烯的摩擦力随其厚度的增加而减小,且单层石墨烯的摩擦力最大;而石墨烯的厚度对其粘附力的影响却不明显。石墨烯的摩擦力也与探针的滑动速度有关,当探针的滑动速度处于0.25 μm/s ~ 2 μm/s时,石墨烯的摩擦力随探针滑动速度的增加而增加,且近似呈对数关系。

4.利用原子力显微镜,采用锥形探针和球形探针测量石墨烯与SiO2/Si基底的边界位置及到石墨烯中心区域的平均摩擦力,发现在锥形探针的作用下,对于单层石墨烯,其中心区域的平均摩擦力明显大于其与SiO2/Si基底的边界位置处的平均摩擦力;而对于多层石墨烯,其中心区域的平均摩擦力与SiO2/Si基底的边界位置处的平均摩擦力相差不大。然而在球形探针的作用下,无论是单层石墨烯还是多层石墨烯,其平均摩擦力随探针作用区域的变化都不明显。

关键词:原子力显微镜,石墨烯,锥形探针,球形探针,摩擦特性

FRICTION CHARACTERISTICS OF GRAPHENE BASED ON MULTI-SCALE SPHERICAL PROBE

ABSTRACT

Friction was everywhere in life, such as from drilling wood to making fire in ancient times to friction involved in micro nano devices at present, ranging from macro scale to micro scale. However, when the device was under the micro nano scale, the friction system can not be simply equivalent to the macro friction system with reduced size. Graphene, as a new two-dimensional carbon material, due to the miniaturization and the micrminiaturization of the size of the colloidal probe, its specific surface area greatly increased, thus the surface effect significantly enhanced, and the tribological problem was particularly prominent. In this paper, the friction properties of graphene were studied by conical probe and spherical probe with different radius of curvature. The main content of this paper was follows:

Using AFM, the morphology of graphene was characterized by conical probe and spherical probe with different radius of curvature in tap mode. It was found that the the thickness of graphene increased with the increase of the radius of curvature of the tip.

The friction and adhesion between graphene and conical probe and spherical probe with different radius of curvature were measured by AFM in lateral force mode. It was found that the friction and adhesion of graphene increased with the increase of the radius of curvature.

Using AFM, the effects of the probe's sliding speed, external load and the thickness of graphene on its friction force were investigated. It was found that the friction force of graphene increased with the increase of external load, and it was approximately linear; When the applied normal load was close to the adhesion force, the friction force of graphene did not depend on the normal load; When the difference between normal load and adhesion force was a bit large, the friction force of graphene increased linearly with the increase of normal load. The friction force of graphene decreased with the increase of its thickness, and the friction force of single-layer graphene was the largest. However, the adhesion of graphene varied little with its thickness. When the sliding velocity of the probe was between 0.25 μm/s ~ 2 μm/s, the friction force of graphene increased with the increase of the sliding speed of the probe, which was approximately logarithmic.

The conical probe and spherical probe were used to measure the average friction from the boundary region between graphene and SiO2/Si substrate to the central region of graphene. The results showed that for single-layer graphene, the average friction force in the central region of graphene was significantly greater than that in the boundary region under the action of conical probe, while the average friction force of graphene varied little with the selected region under the action of spherical probe. For multilayer graphene, the average friction force of graphene varied little with the selected region under the action of two kinds of probes.

Keywords:atomic force microscopy,graphene,conical probe,spherical probe,frictional properties

Qian Yu(Mechanical Engineering)

Supervised by Dai Huiliang

目 录

摘要

ABSTRACT

目录

第一章 绪论 ……………………………………………………………………1

1.1课题的研究背景及研究意义…………………………………………… 1

1.2石墨烯的结构和性能…………………………………………………… 1

1.3 胶体探针技术…………………………………………………………… 3

1.3.1胶体探针的制备………………………………………………………3

1.3.2 微球制造方法……………………………………………………… 3

1.3.3 微球粘结方法……………………………………………………… 3

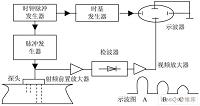

1.4 原子力显微镜…………………………………………………………… 4

1.4.1 原子力显微镜简介………………………………………………… 4

1.4.2 原子力显微镜的工作原理………………………………………… 4

1.4.3 原子力显微镜的工作模式………………………………………… 5

1.4.4 原子力显微镜微悬臂弹性常数的测定…………………………… 6

1.5 国内外的研究现状……………………………………………………… 8

1.5.1 球形探针的应用…………………………………………………… 8

1.5.2 基于多尺度球形探针石墨烯摩擦特性的研究现状……………… 8

1.6 本文主要研究内容以及研究技术路线………………………………… 9

第二章 探针针尖半径变化影响石墨烯表面形貌检测的理论分析 ………… 11

2.1 引言……………………………………………………………………… 11

2.2 探针针尖半径变化对石墨烯表面形貌检测的影响…………………… 11

2.2.1 探针针尖半径变化对石墨烯表面形貌检测影响的实验结果…… 11

2.2.2 探针针尖半径变化对石墨烯表面形貌检测影响的理论分析…… 14

2.3 本章小结………………………………………………………………… 15

第三章 探针针尖半径变化影响探针针尖与石墨烯表面力的分析 ………… 16

3.1 引言……………………………………………………………………… 16

3.2 探针针尖半径变化对针尖与石墨烯粘附力的影响…………………… 16

3.2.1 探针针尖半径变化对其与石墨烯粘附力影响的实验结果……… 16

3.2.2 探针针尖半径变化对其与石墨烯粘附力影响的理论分析……… 18

3.3 探针针尖半径变化对针尖与石墨烯摩擦力的影响…………………… 19

3.3.1 探针针尖半径变化对其与石墨烯摩擦力影响的实验结果……… 19

3.3.2 探针针尖半径变化对其与石墨烯摩擦力影响的理论分析……… 20

3.4 原子尺度的粘滑(stick-slip)…………………………………………… 20

3.5 本章小结………………………………………………………………… 22

第四章 载荷、速度以及厚度对石墨烯纳米摩擦力的影响 ………………… 23

4.1 实验准备………………………………………………………………… 23

4.2 法向载荷对石墨烯摩擦力的影响……………………………………… 23

4.2.1 法向载荷对石墨烯摩擦力影响的实验结果……………………… 23

4.2.2 法向载荷对石墨烯摩擦力影响的理论分析……………………… 24

4.3 厚度对石墨烯摩擦力的影响…………………………………………… 25

4.3.1 厚度对石墨烯摩擦力影响的实验结果…………………………… 25

4.3.2 厚度对石墨烯摩擦力影响的理论分析…………………………… 25

4.4 探针的扫描速度对石墨烯摩擦力的影响……………………………… 26

4.4.1 探针的扫描速度对石墨烯摩擦力影响的实验结果……………… 26

4.4.2 探针的扫描速度对石墨烯摩擦力影响的理论分析……………… 27

4.5 本章小结………………………………………………………………… 27

第五章 边界效应对石墨烯纳米摩擦力的影响 ……………………………… 29

5.1 实验过程………………………………………………………………… 29

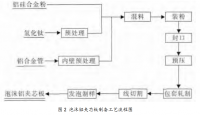

5.1.1 石墨烯的制备……………………………………………………… 29

5.1.2 石墨烯的表征……………………………………………………… 31

5.1.2.1 石墨烯的光学图像分析……………………………………… 31

5.1.2.2 石墨烯的AFM高度图像分析……………………………… 31

5.2 边界效应对不同探针作用下石墨烯摩擦力的影响…………………… 32

5.3 不同厚度石墨烯的原子尺度粘滑行为……………………………………34

5.4 基底和多层石墨烯的粘附力比较……………………………………… 40

5.5本章小结………………………………………………………………… 42

第六章 总结与展望 …………………………………………………………… 43

6.1 全文工作总结…………………………………………………………… 43

6.2 后续工作展望…………………………………………………………… 44

参考文献 ………………………………………………………………………… 45

附录 ……………………………………………………………………………… 51

攻读硕士学位期间科研成果 …………………………………………………… 52

致谢 ……………………………………………………………………………… 53

第一章 绪论

1.1 课题的研究背景及研究意义

在微纳尺度下对机械器件性能进行研究的过程中,相关的研究人员开发出了一个新的应用系统,也就是之后的微/纳机电系统。它是一个综合应用系统,其融合了微型传感器、执行器、微型机构以及信号识别与处理和电路集成的所有功能,因此其在环境检测、新能源电池、光学器件、生物医疗、以及航空航天等领域得到了广泛的应用[1-2]。

随着纳米技术的不断进步,微/纳机电系统(MEMS/NEMS)逐渐地被应用于航空航天、医疗器件和生物技术以及环境检测等众多领域,因此,必需要进一步地完善微纳器件的结构及性能。与传统的机械零部件相比[3-5],粘着以及微摩擦问题更加困扰着微型器件。主要是由于微型器件的外观尺寸比较微小,其表面积的数值相对于其体积而言,数量级较大[6],从而使其表面效应尤为明显,同时由于构件之间的紧密接触等,使得微纳器件的装拆、工作运转性能以及使用寿命等受到了微/纳粘着以及微摩擦的影响,从而在一定程度上制约了微/纳机电系统的实际应用和发展 [7-11]。因此,我们需要进一步地探究制约微/纳机电系统应用及发展的微摩擦、粘着以及磨损的问题,从而提高器件运转性能并延长其使用寿命。

由于应用于宏观物体表面减摩的方法对微纳器件间的减摩效果并不显著,因此,需要我们从微/纳尺度角度研究两接触表面之间的力学性能,进一步地探究其粘着以及微摩擦的机理,这为研制微纳器件以及对其表面进行防护提供了一定的理论指导作用。

参考文献

[1] Kraff D M. Micromachined inertial sensors: the state of the art and a look into the future[J].Measurement Control, 2000, 33: 164-168.

[2] 丁衡高.微机电系统的科学研究和技术开发[J].清华大学学报,1997, 37(9):1-5.

[3] D.S. Grierson, A.R. Konicek, G.E. Wabiszewiski, A.V. Sumant, M.P. de Bor, A.D. Corwin, R.W. Carpick, Characterization of Microscale Wear in a Polysilicon-Base d MEMS Device Using AFM and PEEM-NEXAFS Spectromicroscopy, Tribology Letters, 36 (2009) :233-238.

[4] W.J. Zhao, L.P. Wang, Q.J. Xue, Design and fabrication of nanopillar patterned Au textures for improving nanotribological performance, ACS Applied Materials & Interfaces, 2 (2010) : 788-794.

[5] B. Bhushan, M. palacio, B. Kinzig, AFM-based nanotribological and electrical characterization of ultrathin wear-resistant ionic liquid films, Journal of Colloid and Interface Science, 317 (2008) : 275-287.

[6] S.H. Kim, D.B. Asay, M.T. Dugger, Nanotribology and MEMS, Nano Today, 2 (2007) : 22-29.

[7] R.A. Singh, E.S. Yoon, Friction of chemically and topographically modified Si(100) surfaces, Wear, 263 (2007) : 912-919.

[8] M. Zou, L. Cai, H. Wang, Adhesion and friction studies of a nano-textured surface produced by spin coating of colloidal silica nanoparticle solution, Tribology Letters, 21 (2006) : 25-30.

[9] M. Nosonovsky, B. Bhushan, Multiscale friction mechanisms and hierarchical surfaces in nano- and bio-tribology, Materials Science & Engineering R-Reports, 58 (2007) : 162-193.

[10] E.S. Yoon, R.A. Singh, H.J. Oh, H. Kong, The effect of contact area on nano/micro-scale friction, Wear, 259 (2005) : 1424-1431.

[11] H. Wang, R.P. Nair, M. Zou, P.R. Larson, A.L. Pollack, K.L. Hobbs, M.B. Johnson, O.K. Awitor, Friction study of a Ni nanodot-patterned surface, Tribology Letters, 28 (2007) : 183-189.

[12] 宋晓辉.石墨烯/聚合物纳米复合材料的制备及性能研究[D]: 南开大学. 2011

[13] Novoselov KS, Geim AK, Morozov SV, et al. Electric field effect in atomically thin carbon films [J]. science, 2004, 306 (5696) : 666-669.

[14] 杨全红, 吕伟, 杨永岗等. 自由态二维碳原子晶体单层石墨烯[J]. 新型炭材料,2008, 23 (2) : 97-103.

[15] Ghosh A, Subrahmanyam KS, Krishna KS, et al. Uptake of H2 and CO2 by graphene[J].The Journal of Physical Chemistry C: 2008, 112 (40) : 15704-15707.

[16] Lee C, Wei X, Kysar JW, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene[J]. science: 2008, 321 (5887) : 385-388.

[17] Ago H, Ogawa Y, Tsuji M, et al. Catalytic growth of graphene: toward large-area single-crystalline graphene[J]. The journal of physical chemistry letters, 2012, 3 (16) : 2228-2236.

[18] Wang S, Tambraparni M, Qiu J, et al. Thermal expansion of graphene composites [J]. Macromolecules, 2009, 42 (14) : 5251-5255.

[19] Novoselov K S, Fal V I, Colombo L, et al. A roadmap forgraphene[J]. Nature, 2012, 490 (7419) : 192-200.

[20] Neto A H C. Another spin on graphene[J]. Science, 2011, 332 (6027) : 315-316.

[21] W.A.Ducker, T.J.Senden, R.M.Pashley. Direct measurement of Colloidal Forces using an Atomic Force Microscope. Nature. 1991, 353 (6341) : 239-240.

[22] H.-J.Butt. Measuring Electrostatic, van der Waals, and Hydration Forces in Electrolyte Solutions with an Atomic Force Microscope. Biophys.J.1991, 60 (6): 1438-1444.

[23] L.Meagher, G.Maurdev, M.L.Gee. Interaction Forces between a Bare Silica Surface and an α-Alumina Surface Bearing Adsorbed Polyelectrolyte and Surfactant. Langmuir. 2002, 18 (7) : 2649-2657.

[24] G.J.C. Braithwaite, A.Howe, P.F.Luckham. Interactions between Poly (ethyleneoxide) Layers Adsorbed to Glass Surfaces Probed by Using a Modified Atomic Force Microscope. Langmuir. 1996, 12 (17) : 4224-4226.

[25] E.Kokkoi, C.F.Zukoski. Interaction Forces between Hydrophobic and Hydrophilic Self-assembled Monolayers.J. Colloid Inter. Sci. 2000, 230 : 176-180.

[26] H.G.Pedersen, L.Bergstrom. Forces Measured between Zirconia Surfaces in Poly (acrylic acid) Solutions.J.Am.Ceram.Soc.1999, 82 (52) : 1137-1145.

[27] T.Kakui, T.Miyauchi, H.Kamiya. Analysis of the Action Mechanism of Polymer Dispersant on Dense EthanolAluminaSuspension using Colloidal Probe AFM. J. Eur. Ceram. Soc. 2005, 25 (5) : 655-661.

[28] S.Huntington, S.Nespolo. Precision Attachment of Silica Spheres to AFM Cantilevers Tips. Microscopy Today. 2001, 9 (2) : 32-38.

[29] Y.Gan. A Simplified Technique to Attachment Sphere to AFM Cantilever. Today. 2005, 11 (13) : 48-49.

[30] 杨序纲,杨潇.原子力显微镜及其应用.北京:化学工艺出版社,2012:19-30.

[31] 王岳宇. AFM恒力模式下倾角和摩擦力对测量结果影响的研究. 哈尔滨:哈尔滨工业大学,2008.

[32] 彭昌盛,宋少先,谷庆宝. 扫描探针显微技术理论与应用. 北京: 化学工艺出版社,2007 : 11-12.

[33] Tortonese M. Cantilevers and Tips for Atomic Force Microscopy. IEEE in Engineering Medinine and Biology. 1997, 16 (2) : 28-33.

[34] 陈新强. 二氧化硅胶体探针微球磨损过程的原子力显微镜研究.哈尔滨: 哈尔滨工业大学,2010.

[35] 李卫东,李彦.七孔探针三维自动测速系统. 北京: 清华大学,2005.

[36] 陈克冰,刘少喻,李浩森. 球形探针技术在椎弓根螺钉置钉术中的应用. 中华骨科杂志,2011,31 (12) : 1314-1318.

[37] 曾国平,向东山. 金纳米粒子作探针共振瑞利散射光谱法测定牛奶中三聚氰胺. 武汉: 湖北第二师范学院,2011.

[38] 刘超,张爱兵,孙越强. 电磁监测试验卫星朗缪尔探针电离层探测技术. 北京: 中国科学院国家空间科学中心,2016.

[39] 唐海林,过源,陈瑜莉. 靶向诊疗一体化纳米探针US/MRI双模态成像及增效高强度聚焦超声治疗的体外实验. 中华骨科杂志,2018,26 (3) : 165-174.

[40] 陈新强. 二氧化硅胶体探针微球磨损过程的原子力显微镜研究. 哈尔滨: 哈尔滨工业大学,2010.

[41] 薛勃. AFM单晶硅探针磨损的实验研究. 哈尔滨: 哈尔滨工业大学,2012.

[42] 杨延婷. 基于AFM和DIC的探针纳米尺度磨损实验研究. 哈尔滨: 哈尔滨工业大学,2013.

[43] 詹胜鹏. 微纳尺度接触和摩擦过程力学行为分子动力学及多尺度模拟研究.昆明理工大学,2013.

[44] 窦建华. 原子力显微镜针尖—表面相互作用分子动力学仿真研究. 哈尔滨: 哈尔滨工业大学,2009.

[45] R B M, Acunto.D.Nanotribology: Tip-sample Wear under Adhedive Contact. Tribol INT. 2000, 33 (7) : 443-452.

[46] Chung K H, Lee Y, Kim D E. Characteristics of Fracture during the Approach Process and Wear Machanism of a Silicon AFM tip. 2005, 102 (2) : 161-171.

[47] 闫永达,伊大勇,费维栋等. AFM针尖磨损机理研究进展. 航空精密制造技术. 2008,44 (3) : 6-8.

[48] L. Liu Wear of Silicon and Carbon-Based Nanoscale Asperities. STLE/ASME 2008 International Joint Tribology Conference. 2009 : 37.

[49] R. Agrawal, N. Moldovan, H.D. Espinosa. An Energy-based Model to Predict Wear in Nanocrystalline Diamond Atomic Force Microscopy Tips. J. Appl. Phys.2009, 106 (6) : 064311.

[50] 徐相杰. 不同接触尺度下单晶硅的摩擦磨损性能研究. 成都: 西南交通大学,2012.

[51] Amirfazli A, Neumann A.W.Status of the three-phase line tension: a review. Advances in Colloid and Interface Science[J], 2004, 110 (3) :121-141.

[52] 谢浩添. 石墨表面的湿润性及其调控研究[D]. 哈尔滨:哈尔滨工业大学,2018.

[53] Bhushan B. Nanotribology and nanomechanics of MEMS/NEMS and BioMEMS/BioNEMS materials and devices. Microelectronic Engineering[J], 2007, 84 (3):387-412.

[54] C Gao, P Dai, Homola A, et al. Menisus Forces and Profiles: Theory and Its Applications to Liquid-Mediated Interfaces. Journal of Tribology[J], 1998, 120 (2):358.

[55] 刘思思,张朝辉,周杰,何建国. 微/纳器件粗糙表面间弯月面力以及黏着力计算[J]. 计算力学学报,2014,31(04):532-536.

[56] K. L.Johnson, K. Kendall, A. D. Roberts. Surface Energy and the Contact of Elastic Solids. Proceedings of the Royal Society A Mathematical[J], 1971, 324 (1558) : 301-313.

[57] Paolicelli G, Tripathi M, Corradini V, et al. Nanoscale frictional behavior of graphene on SiO2 and Ni(111) substrates. Nanotechnology[J], 2015, 26 (5) : 055703.

[58] Lee C, Wei X, Kysar J W, et al. Measurement of the Elastic Properties and Intrinsic Strength of Monolayer Graphene. Science[J], 2008, 321 (5887) : 385-388.

[59] Nikhil S Tambe and Bharat Bhushan. Scale dependence of micro/nano-friction and adhesion of MEMS/NEMS materials, coatings and lubricants[J]. Nanotechnology, 2004, 15 : 1561-1570.

[60] Haozhi Yuan, Jinyu Zhang, and Yaqiang Wang, et al. Curvature-Controlled Wrinkling Surfaces for Friction[J]. Adv. Mater. 2019, 31: 1900933.

[61] Mate, C.M., McClelland, G.M, Erlandsson, R.. Atomic-scale friction of atungsten tip on a graphite surface[J]. Phys. Rev. Lett. 1987, 59 : 194-245.

[62] Albert, I, Tegzes, Albert, R.. Stick-slip fluctuations in granular drag[J]. Phys.Rev.E. 2001, 64 : 031307.

[63] Riedo, E, Gnecco, E, Bennewitz,et al. Interaction Potential and Hopping Dynamics Governing Sliding Friction[J]. Phys. Rev. Lett. 2003, 91 : 084502.

[64] Schirmeisen, A, Jansen, L. and Fuchs, H. Tip-jump statistics of stick-slip friction[J]. Phys.Rev.B. 2005, 71 : 245403.

[65] Reimann, P, and Evstigneev M. Nonmonotonic Velocity Dependence of Atomic Friction[J]. Phys. Rev. Lett. 2004, 93 : 230802.

[66] Rozman, M. G. Origin of stick-slip motion in a driven two-wave potential[J]. Phys.Rev.E. 1996, 54 : 6485.

[67] Mulliah, D, Kenny, S. D, and Smith, Roger. Modeling of stick-slip phenomena using molecular dynamics[J]. Phys.Rev.B. 2004, 69 : 205407.

[68] Sills, Sand. and Overney, R.M. Creeping Friction Dynamics and Molecular Dissipation Mechanisms in Glassy Polymers[J]. Phys. Rev. Lett. 2003, 91 : 095501.

[69] Laengle T, Lueth T C, Rembold U, A Distributed Control Architecture for Autonomous Robot Systems, Modelling and Planning for Sensor Based Intelligent Robot Systems,1995 : 384-402.

[70] Luengo, Gustavo, Israelachvili, Jacob, Granick Steve. Generalized effects in confined fluids: new friction map for boundary lubration[J]. wear, 1996, 200 (328) .

[71] Aranson, I.S., Tsimring, L.S. and Vinokur, V. M. Stick-slip friction and nucleation dynamics of ultrathin liquid films[J]. Phys. Rev. B. 2002, 65 : 125402 .

[72] Li Bin, Zhang X.M. Molecular dynamics simulation of stick-slip[J].J. Appl.Phys. 2001, 90 (6) : 3090.

[73] Zhang, L.C., Johnson K.L and Cheong W.C.D. A molecular dynamics study of scale effects on the friction of single-asperity contacts.

[74] Persson, B.N. J.. Friction dynamics for curved solid surfaces with long-range elasticity[J]. J. Chem. Phys. 2000, 113 (13) : 5477.

[75] Schirmeisen, A., Jansen, L, and Fuchs.H. Tip-jump statistics of stick-slip friction[J]. Phys. Rev. B, 2005, 71 : 245403.

[76] L. Prandtl, Gedankenmodell zur kinetischen theorie der festen korper, Z. Angew. Math. Mech, 1928, 8 : 85-106.

[77] G. A. Tomlinson, CVI. A molecular theory of friction, Lond. Edinb. Dublin Phil.Mag. J. Sci, 1929, 7 : 905- 939.

[78] C. Lee, Q.Y. Li, W. Kalb, X.Z. Liu, H. Berger, R.W. Carpick, J. Hone, Frictional characteristics of atomatically thin sheets. Science, 2010, 328 (5974) : 76-80.

[79] Yitian Peng, Xingzhong Zeng, Kang Yu, et al. Deformation induced atomic-scale frictional characteristics of atomically thin two-dimensional materials. Carbon, 2020, 163 : 186-196.

[80] Belak J F. Nanotribology. Mrs Bulletin, 1993, 18 (5) : 15-19.

[81] Bowdn F P, Tabor D. The Friction and Lubrication of Solids [M]. Clarendon Press, Oxford, 1950 : 87-396.

[82] Filleter T, Bennewitz R. Structural and frictional properties of graphene films on SiC(0001) studied by atomic force microscopy[J]. Physical Review B, 2010, 81 (15) :155412.

[83] Filleter T, McChesney J L, Bostwick A, et al. Friction and Dissipation in Epitaxial Graphene Films[J]. Physical Review Letters, 2009, 102 (8) : 086102.

[84] Lee H, Lee N, Seo Y, et al. Comparison of frictional forces on graphene and graphite[J]. Nanotechnology, 2009, 20 (32) : 325701.

[85] Lee C, Wei X D, Li Q Y, et al. Elastic and frictional properties of graphene[J]. Physica Status Solidi B-Basic Solid State Physics, 2009, 246 (11-12) : 2562-2567.

[86] Lee C, Li Q Y, Kalb W, et al. Frictional Characteristics of Atomically Thin Sheets[J]. Science, 2010, 328 (5974) : 76-80.

[87] Krylov S Y, Jinesh K B, Valk H, et al.Thermally induced suppression of friction at the atomic scale [J]. Physical Review E, 2005 , 71 (6) : 065101-065104.

[88] Riedo E, E.Gnecco. Thermally activated effects in nanofriction [J]. Nanotechnology , 2004, 15 (4) : S288-S292.

[89] Gnecco E, Bennewitz R, Gyalog T, et al. Velocity dependence of atomic friction [J]. Physical Review Letters, 2000, 84 (6) : 1172-1175.

[90] Reimann P, Evstigneev M.Nonmononic velocity dependence of atomic friction[J]. Physical Review Letters, 2004, 93 (23) : 230802.

[91] Evstigneev M, Reimann P. Rate description of the stick-slip motion in friction force microscopy experiments [J]. Physical Review E, 2005, 71 (5) : 056119.

[92] Evstigneev M, Reimann P. Refined force-velocity relation in atomic friction experiments[J]. Physical Review B, 2006, 73 (11) : 113403.

[93] Dudko O K, Filippov A E, Klafter J, et al. Control of friction by shear induced phase transitions[J]. Physical Review B, 2002, 66 (9) : 094114.

[94] Chen J, Ratera I, Park J Y, et al. Velocity dependence of friction and hydrogen bonding effects[J]. Physical Review B, 2006, 96 (23) : 236102.

[95] Riedo E, Levy F, Brune H. Kinetics of capillary condensation in nanoscopic sliding friction[J]. Physical Review Letters, 2002, 88 (18) : 185505-4.

[96] Zworner O, Holscher H, Schwarz U D, et al. The velocity dependence of frictional forces in point-contact friction[J]. Applied Physics a-Materials Science &Processing, 1998, 66 : S263-S267.

[97] Sang Y, Dube M, Grant M. Dependence of friction on roughness, velocity, and temperature[J]. Physical Review E, 2008, 77 (3) :036123.

[98] Sang Y, Dube M, Grant M. Thermal effects on atomic friction[J]. Physical Review Letters, 2001, 87 (17) :174301-174304.

[99] Riedo E, Brune H.Young modulus dependence of nanoscopic friction coefficient in hard coatings[J]. Applied Physics Letters, 2003, 83 (10) : 1986-1988.

[100] Bilas P, Romana L, Kraus B, et al. Quantitative characterization of friction coefficient using lateral force microscope in the wearless regime[J]. Review of Scientific Instruments, 2004, 75 (2) : 415-421.

[101] Krylov S Y, Jinesh K B, Valk H, et al. Thermally induced suppression of friction at the atomic scale [J]. Physical Review E, 2005, 71 (6) : 065101-065104.

[102] Riedo E, E.Gnecco. Thermally activated effects in nanofriction [J]. Nanotechnology, 2004, 15 (4) : S288-S292.

[103] Bolotin K I, Sikes K J. Jiang Z. et al. Ultrahigh electron mobility in suspended graphene [J]. Solid State Communications, 2008, 146 (9-10) : 351-355.

[104] Chen J H, Jang C, Xiao S D, et al. Intrinsic and extrinsic performance limits of graphene devices on SiO2 [J]. Nature Nanotechnology, 2008, 3 (4) : 206-209.

[105] Lee C, Wei X, Kysar J W, et al. Measurement of the elastic properties and intrinsic strength of monolayer graphene [J]. Science, 2008, 321 (5887) : 385-388.

[106] Lee C, Wei X D, Li Q Y, et al. Elastic and frictional properties of graphene [J]. Physica Status Solidi B-Basic Solid State Physics, 2009, 246 (11-12) : 2562-2567.

[107] Stark R W, Drobek T, Heckl W M. Thermomechanical noise of a free v-shaped cantilever for atomic force microscopy. Ultra-microscopy, 2001, 86 (1-2) : 207-215.

[108] Sader J E, Sanelli J A, Adamson B D, et al. Spring constant cali-bration of atomic force microscope cantilevers of arbitrary shape. Review of Scientific Instruments, 2012, 83 (10) : 103705.

[109] Li Q, Kim K S, Rydberg A. Lateral force calibration of an atomic force microscope with a diamagnetic levitation spring system. Review of scientific instruments, 2006 , 77 (6) : 065105.

[110] Novoselov K S, Geim A K, Morozov S V, et al., Electric field effect in atomically thin carbon films [J]. Science, 2004, 306 (5696) : 666-669.

[111] Nemes-Incze P, Osva’ tha Z, Kamara’K, et al. Anomalies in thickness measurements of graphene and few layer graphite crystals by tapping mode atomic force microscopy[J]. Carbon, 2008, 46 (11) : 1435-1442.

[112] Leenaerts O, Partoens B, Peeters F M, Adsorption of H2O, NH3, CO, NO2, and NO on graphene: A first-principles study [J]. Physical Review B, 2008, 77 (12) : 125416.

[113] Park C, Anderson P E, Chambers A, et al. Further studies of the interaction of hydrogen with graphite nanofibers[J]. Journal of Physical Chemistry B, 1999, 103 (48) : 10572-10581.

[114] Ghosh A, Subrahmanyam K S, Krishna K S, et al. Uptake of H2 and CO2 by Graphene[J]. J.Phys.Chem.C, 2008, 112 : 15704-15707.

[115] Ohba T, Kanoh H. Intensive Edge Effects of Nanographenes in Molecular Adsorptions[J]. Journal of Physical Chemistry Letters, 2012, 3 (4) : 511-516.

[116] Liang Fang, Da-Meng Liu. Thickness dependent friction on few-layer MoS2, WS2, and WSe2. Nanotechnology, 2017, 28 : 245703.

[117] Lee C, Li Q Y, Kalb W, et al. Frictional Characteristics of Atomically Thin Sheets[J]. Science, 2010, 328 (5974) : 76-80.

[118] Yakobson B I, Brabec C J, Bernholc J. N anomechanics of carbon tubes: Instabilities beyond linear response[J]. Physical Review Letters, 1996, 76 (14) : 2511-2514.

[119] Li Q Y, Lee C, Carpick R W, et al. Substrate effect on thickness-dependent friction on graphene[J]. Physical Status Solidi B-Basic Solid State Physical, 2010, 247 (11-12) : 2909-2914.

[120] Lee H, Lee N, Seo Y, et al. Comparison of frictional forces on graphene and graphite [J]. Nanotechnology, 2009, 20 (32) : 325701.