钻机齿轮轴热处理工艺设计

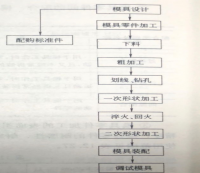

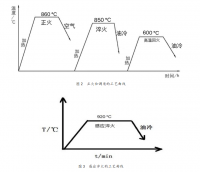

摘要:通过对GXY-2钻机齿轮轴的工作条件的分析,提出工艺要求并且选定材料为20CrMnTi钢,20CrMnTi钢最常用的就是用于作汽车齿轮、齿轮轴等,其基本工艺为:设计下料→锻造成形→等温正火→切削加工→渗碳、淬火+低温回火→喷丸→磨削加工→检验处理,一般可以作到回火后硬度HRC=56~64,通常控制在中间范围.淬火时,通常450℃~500℃预热,强渗区温度在880℃~900℃左右的样子,淬火区可以降到850℃以下淬火,油温稳定在70℃。经过这一系列的工艺流程,最终可得到满足工艺要求的GXY-2钻机齿轮轴。

本文主要论述合金钢20CrMnTi的工艺性能,以及在齿轮轴工艺中的特殊热处理性能,通过本次毕业设计的写作,对热处理有了一定的了解,为以后的工作打下了良好的基础。

关键词:20CrMnTi;齿轮轴;合金钢;热处理工艺

目录

1引言·············································3

2齿轮轴的热处理工艺设计···························6

2.1齿轮轴原材料的选择······································6

2.1.1 满足齿轮轴材料的机械力学性能·····························6

2.1.2 满足齿轮轴的工艺性能·····································7

2.1.3 满足齿轮轴的经济性要求···································7

2.2 齿轮轴的服役条件分析与性能要求··························7

2.2.1 服役条件、失效形式·······································7

2.2.2 主要性能要求·············································8

2.3 齿轮轴材料的选择········································8

2.4 齿轮轴材料的分析········································9

2.5 齿轮轴中合金元素的作用·································9

2.5.1 合金元素在钢中的存在形式·································9

2.5.2 合金元素对组织转变的影响································10

2.5.3 合金元素对力学性能的影响································10

2.6 热处理工艺设计·········································11

2.7 齿轮轴的预备热处理·····································12

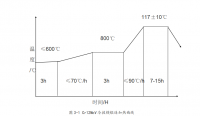

2.7.1 正火工艺设计············································12

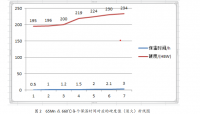

2.7.1.1 正火加热保温时间················································14

2.7.1.2正火的目的·······················································14

2.7.2 调质····················································16

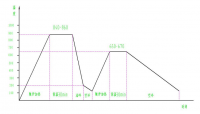

2.8 渗碳处理工艺···········································17

2.8.1 钢的化学成分············································17

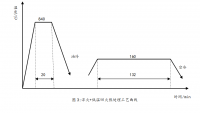

2.8.2 渗碳工艺················································17

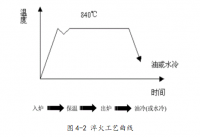

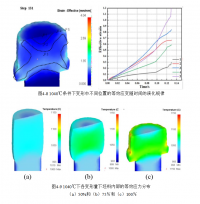

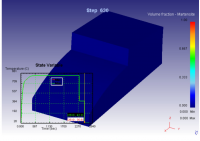

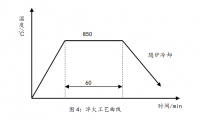

2.8.3 淬火····················································19

2.8.4 20CrMnTi齿轮轴的磨削加工·································20

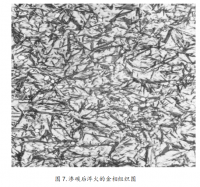

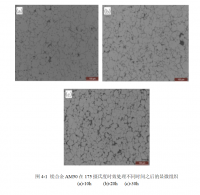

2.8.5 渗碳淬火后的金相组织····································20

2.8.6 低温回火················································22

2.9 喷丸处理···············································24

2.10 20CrMnTi钢热处理工艺曲线·····························24

2.11 各热处理工艺后的金相组织分析··························25

2.12 热处理工艺过程中的质量检验项目························27

2.12.1渗碳淬火后齿轮轴的检验项目。内容和要求···················28

2.12.2 齿轮轴渗碳的常见缺陷及防护措施·························29

3 齿轮轴热处理工艺卡片···························31

4 小结···········································35

5 参考文献·······································36

参考文献

[1] 热处理手册编委会.热处理手册:第三版.第二卷 典型零件热处理[ M]·北京:机械工业出版社,2001,7.

[2] 潘健生,胡明娟 ;热处理工艺学,高等教育出版社,2009.(1).

[3] 王忠诚,齐宝森,李杨;典型零件热处理技术,化学工业出版社,2010.(7).

[4] 张建华,汤志强,张政民;简明热处理手册,北京出版社,1985.(1).

[5] 李泉华. 热处理技术400 问解析[M] . 北京: 机械工业出版社,2005.

[6] 王静平. 铁合金中总碳量准确测定的分析探讨[J] . 山西化工,2002.(5).

[7] 王 静. 影响淬火变形因素的实验分析[J] . 胜利油田职工大学学报,2007.(2).

[8] 徐天祥,等.热处理实用技术手册[M]南京:江苏科学技术出版社,2001.

[9] 胡明娟,潘健生,热处理工艺讲义.上海交通大学内部资料,1983.

[10] 职业技能鉴定指导中心.高级热处理工技术[M].北京:机械工业出版社,2004.

http://www.bysj1.com/ http://www.bysj1.com/html/5215.html http://www.bysj1.com/html/5215.html