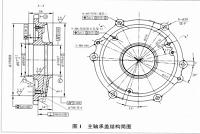

柴油机主轴承盖工艺方案分析及工装设计

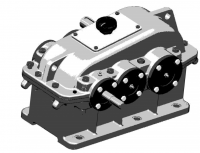

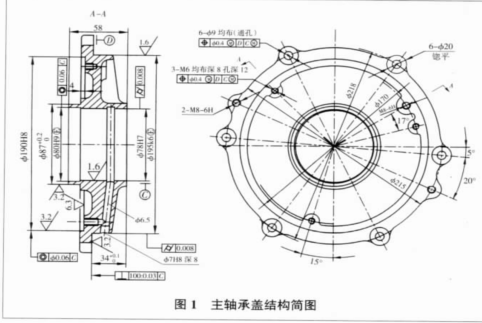

摘要:主轴承盖是单缸柴油机支承曲轴的重要零件。文中对其结构工艺性进行了分析, 提出了加工的关键工序。对目前生产该零件的工艺方法进行了调查, 对实际的不同机械加工工艺从成本、规模、加工精度方面进行了分析, 提出了保证加工精度的措施和适合目前生产状况的经济型工艺方案。同时设计了两道主要工序的夹具和钻工装, 并对其进行了相关分析说明。

关键词:关键词: 主轴承盖; 工艺方案; 加工精度; 工装

Market research on Wuxi electromechanical hardware industry

Abstract:(加粗)This paper is to design the main bearing cap lever spare parts and some specialized tongs in the process. main bearing cap lever spare part primarily processes the surface and bores. Generally speaking, to guarantee the accuracy of the flat surface process is easier than that of the bore. Therefore, this design follows the principle that surface first and then the bore, and definitely divides the process of flat surface and bore into coarse processes and precise processes to guarantee the bore processes. The basic choice is to consider outside circle as rough basis and to consider 25 bore and its next surface as precise basis. The bottom is first processed out to be fixed position basis, and process the bore using the bottom as the precise basis. The whole processes choose the machine bed. In the aspects of tongs choosing, specialized tongs are used. In consideration of the simple construction size of the spare parts, clipping by hands is adopted. It is simple, and the organization design is simple, and can satisfy the design request.

Keywords: craft proces , tongs, fixed position, tight clip

目 录

第一章 绪论..............................................................................................................................................1

第二章 零件的分析................................................................................................................4

2.1零件的作用.....................................................................................................................................4

2.2 零件的工艺分析..............................................................................................................................4

第三章 工艺规程设计...............................................................................................................................9

3.1确定毛坯制造形式...............................................................................................................9

3.2 基准的选择......................................................................................................................................9

3.3工艺路线的制定............................................................................................9

3.4机械加工余量,工序尺寸及毛坯的确定......................................................................................10

3.5确定切削量及基本工时.................................................................................................10

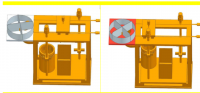

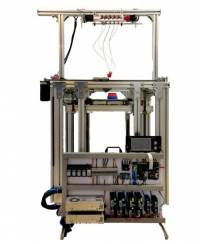

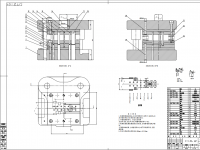

第四章 夹具设计...........................................................................................................32

4.1 问题的提出...................................................................................................32

4.2 定位基准........................................................ ...........................................................................32

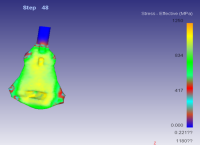

4.3切削力及加紧力的计算.............................................................................................35

4.4.加紧原理..................................................................................38

第六章 回顾总结........................................................................................................................44

6.1课题成果........................................................................................................................44

6.2存在问题........................................................................................................................44

6.3收获体会........................................................................................................................44

致谢........................................................................................................................46

参考文献........................................................................................................................47

附录........................................................................................................................48

附件1:XXX零件机械加工工艺流程图.......................................................................................................48

附件2:XXX零件机械加工工艺过程卡…...................................................................................................49

附件3:XXX零件机械加工工艺工艺卡…...................................................................................................50

附件4:XXX零件机械加工工艺工序卡………….......................................................................................51

附件5:XXX零件零件图…………..............................................................................................................60

附件6:XXX零件毛坯图…………..............................................................................................................61

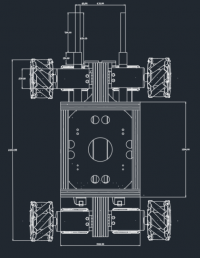

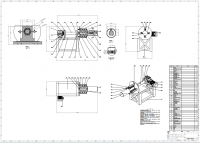

附件7:XXX夹具装配图…………..............................................................................................................62

附件8:XXX夹具零件图…………..............................................................................................................63

附件9:其他系统图……......………..............................................................................................................78

附件10:其他原理图……......………............................................................................................................80

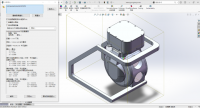

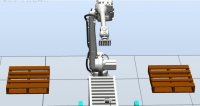

附件11:XXX零件三维造型图……......………...........................................................................................82

附件12:XXX夹具三维造型图……......…….…..........................................................................................83

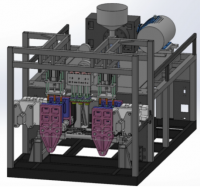

附件13:设计(作品)实物图……......………................................................................................................84

附件14:设计(作品)实物……......………...................................................................................................85

附件15:企业证明……......………................................................................................................................86

附件16:企业合作开发的技术服务合同……......………............................................................................87

附件17:四技服务项目验收表……......………............................................................................................88

附件18:毕业设计(论文)指导记录表……......………................................................................................89

附件19:用人单位毕业设计鉴定表……......………....................................................................................90

第一章 绪论

随着人们生活水平的提高,私家车的产量越来越高,而主轴承盖是单缸柴油机支撑曲轴的重要零件,对柴油机的影响甚至重要,目前使用最多的事农用机械考虑到成本的问题因此对提高零件加工精度, 工艺方案显

参考文献(三号、黑体、居中)

参考文献部分字体采用宋体小5号,间距1.5,其著录格式下面分别示例说明:

[1] 陈浩元.科技书刊标准化18讲[M].北京:北京师范大学出版社,2000. (专著标注示例)

[2] 许强,强力,吴宏亮,等.砂田水热及减尘效应研究[J].宁夏大学学报:自然科学版,2009,30(2):180-182. (期刊文献标注示例)

[3] 张永虎.Bα空间上算子逼近[D].银川:宁夏大学,1997. (学位论文标注示例)

[4] BANG S. Active earth pressure behind retaining walls[J]. Journal of Geotechnical Engineering, 1985, 111(3): 407-412. (英文期刊标注示例)

[5] HELD M,KLOSOWSKIJT J T,MITCHELL J S B. Evaluation of collision detection methods for virtual reality fly throughs[C]//Proceedings of the Senenth Canadian Conference on Computational Geometry, Quebec:Spring,1995:205-210. (会议论文标注示例)

[6] 于广云,李宏波.塌陷区抗变形公路路面结构:中国,ZL200520070646.3[P].2006-05-10. (专利标注示例)

[7] 中国科学院水利部水不保持研究所.黄河流域水文泥沙数据库[DB/OL].[2006-07-25]. http://www. loess.csdb.cn/hyd/user/index.jsp. (电子文献标注示例)

http://www.bysj1.com/ http://www.bysj1.com/html/1015.html http://www.bysj1.com/html/3315.html