油管试压阀的设计与分析

摘要:

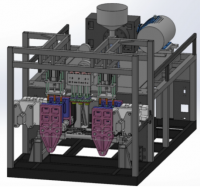

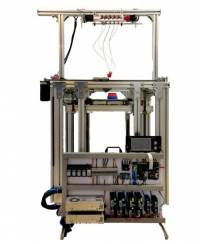

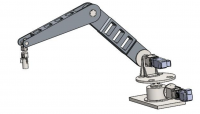

本课题油管试压装置设计。该产品应用于海上油田勘探和开采油田打井的快速钻井技术中。设计在原有试压装置的基础上,进行一些技术上的改进,通过机械电气控制将机械、液压、电气等技术融合在一起,使新装置在钻井效率、降低成本、简化工艺等方面有很好的发展,使其更具自动化和人性化。在这里,主要进行的是机械和电气控制系统的设计。

关键词:螺纹、套管、试压阀

Abstract:

The question for discuss—— the design of a equipment for the screw bushing’s pressurization and trial pressure, is a program of technique alteration in Hezhong corporation of south sea. The screw bushing which is mainly applied in the exploitation of flat roof on the sea, is a new product of this corporation in 2001. Based on the equipment which is now in use, the design make some technique alterations. It melt mechanism、fluid drive and electric in a pot with the help of mechanical and electric control. As a result, the new equipment is more automatic and is full of humanism than before. In here, the main tasks are the design of mechanism and electric control system.

Key words: screw、bushing、trial pressure 、mechatronics、automatization

第一章 系统方案的拟定.

1,螺纹套管的夹紧机构仍采用合众近海建设公司的作业现场的相同。虽然操作上有点不方便,但从经济上考虑,从产量方面考虑,从夹紧的可靠性考虑,采用现场设备,真正做到最大可能地利用原有设备。

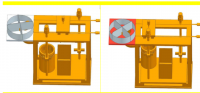

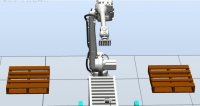

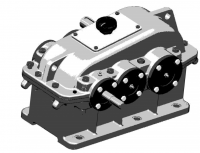

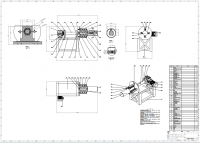

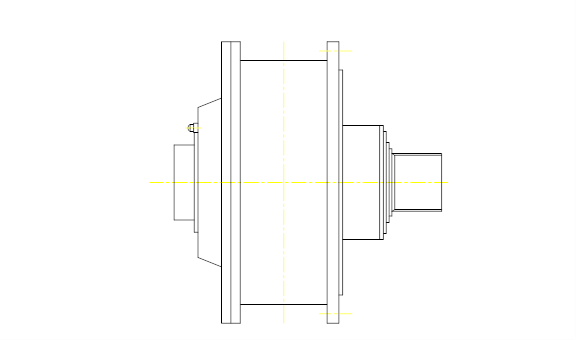

2,拧紧机构采用液压马达带动旋转拨盘拨动螺纹堵头,将螺纹堵头旋进套管.采用的液压马达的扭矩很大,可达到23000Nm拧紧力,动力很大,能达到螺纹套管所要承受的扭矩负载,省去了一个庞大的传动系统,使机构简单紧凑。

3,因螺纹套管两头都要安装堵头,为节省时间,提高工作效率,堵头的旋进采用两边同时进行,即两边运动机构除旋转堵头不同外(一个为内螺纹,一个为外螺纹),其余部分均可做的相同,从工艺方面考虑,不用采用两套不同的工艺,在制造时,应使两边的零部件具有互换性,从而简化工艺,提高系统的性价比。

4,系统的拧紧部份的传动链如下:电动机----液压泵-----液压马达-----联轴器-----旋转拨盘-----堵头。

5,整个系统的控制采用电气控制。

6,在此基础上,拟画螺纹套管试压装置原理图.

目 录

中英文摘要··········································1

序言·················································6

第一篇 机械部份设计

第一章 系统方案的拟定······························7

第二章 机械部份各部件的设计校核及选用··············8

§1—1 夹具部份···································8

§1-2 液压马达···································8

§1-3 联轴器·····································9

§1-4 滚动轴承··································10

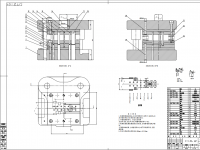

§1-5 拨盘的设计与校核··························11

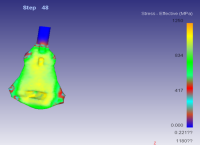

§1-6 堵头的设计与校核··························12

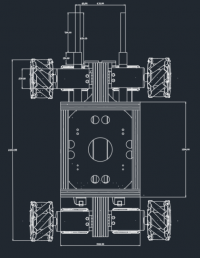

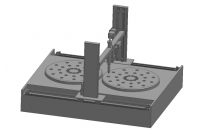

§1-7 移动工作台支承体重量估计··················13

§1-8 导轨的设计································14

§1-9 支架的设计································17

第二篇 电气部份设计

第三章 电气线路设计·······························18

§2-1 主回路设计·······························18

§2-2 控制回路设计·····························18

§2-3 控制电路电源·····························19

§2-4 绘制电气原理图···························19

第四章 选择电器元件·······························20

§3-1 电源引入开关·····························20

§3-2 热继电器·································20

§3-3 熔断器···································20

§3-4 接触器···································20

§3-5 行程开关·································21

§3-6 压力继电器·······························21

§3-7 控制按钮·································21

§3-8 信号灯···································21

总结

总 结··········································24

鸣 谢··········································25

参考文献···········································25

参考文献

1、雷天觉·新编液压工程手册·机械工业出版社,1999,12

2、机械设计手册编写组·机械设计手册(1-5册)·机械工业出版社,1998

3、机械制图手册编写组·机械制图手册·机械工业出版社,1998,12

4、实用机床设计手册·机械工业出版社,

5、刘鸿文·材料力学(第三版)·高等教育出版社,1992

6、互换性与技术测量·中国计量出版社,2000

7、机械设计(第六版)·高等教育出版社,1996

8、齐占庆·机床电气控制技术·机械工业出版社,1999

9、机床设计手册·机械工业出版社,1986

10、实用机械电气技术手册·机械工业出版社

http://www.bysj1.com/ http://www.bysj1.com/html/5215.html http://www.bysj1.com