数控铣床铣刀头座体的工艺分析及加工方法 摘 要

通过对数控铣床进行的调查研究,发现在日常的生产中,数控铣床已经普及了各个工厂,涉及到的领域极为广泛,数控铣床的加工效率是体现出厂家生产效率的关键。但是,调查发现,现在的数控铣床的加工能力已经远远达不到生产的需求,所以说,必须要对数控铣床进行改造,提高生产效率。经过调查发现数控铣床铣刀头的座体的改进是提高数控铣床生产效率的关键,通过对座体的设计、座体的选材、工序的拟定、机床的选择、座体的加工等流程最终完成此次毕业设计,使数控铣床效率得到提高。经过此次毕业设计一方面进一步加深了对所学理论的认识,另一方面在老师的指导下,学会运用所学知识去分析和解决一些实际问题,学会应用手册、标准、规范等资料。把以前所学理论知识运用于实践,从而达到温故而知新的目的,提高我们解决实际工程课题的能力。

关键词:座体的设计 工序的拟定 座体的加工

············································III

毕业设计调研报告······························································IV

摘要··········································································VI

Abstract······································································VII

第一章 引言···································································1

1.1设计题目··································································1

1.2课题来源····································································1

1.3课题类型 ···································································1

1.4课题意义 ···································································1

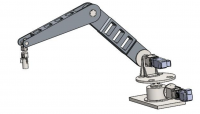

1.5数控铣床的定义及其发展历史··················································1

1.5.1定义·······································································1

1.5.2数控铣床的发展历史·························································1

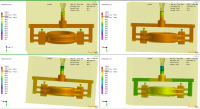

第二章 数控铣床铣刀头座体的工艺分析及加工方法总体设计方案·····················3

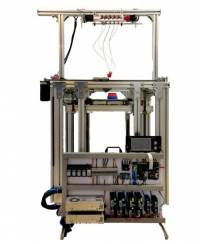

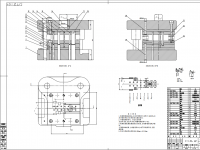

第三章 座体的工艺设计·························································5

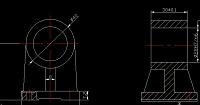

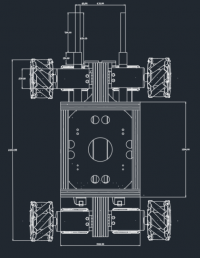

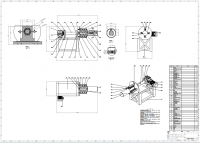

3.1座体的结构工艺性分析 ·······················································5

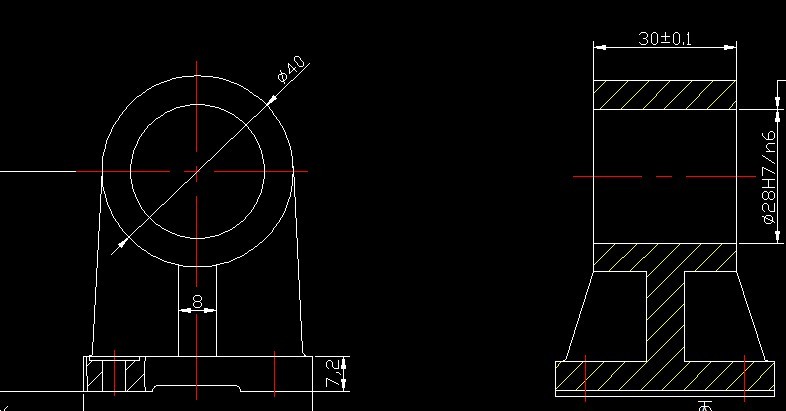

3.1.1座体的尺寸和公差··························································5

3.1.2座体的组成要素····························································5

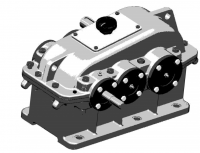

3.1.3座体的整体结构····························································5

3.2生产纲领的确定······························································5

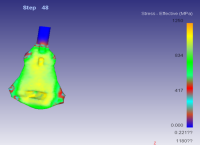

3.3座体的选材··································································7

3.3.1满足材料的使用性能要求····················································7

3.3.2满足材料的工艺性能需求····················································8

3.4毛坯及工序尺寸公差的确定···················································9

3.5工艺路线的拟定·····························································10

3.5.1加工方法的确定····························································10

3.5.2加工阶段的划分····························································11

3.5.3工序集中和分散···························································11

3.5.4加工顺序的确定····························································11

3.6定位基准的选择·····························································12

3.6.1粗基准的选择······························································12

3.6.2精基准的选择······························································12

3.6.3各表面加工时的定位基准····················································13

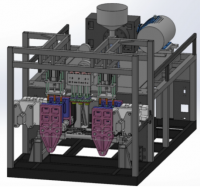

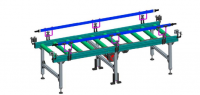

3.7机床及其工艺设备的选择·····················································13

3.7.1机床的选择································································13

3.7.2工艺设备的选择···························································13

3.8切削用量参数的确定························································13

3.9工时定额计算·······························································14

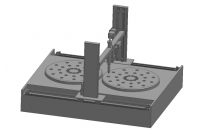

第四章 工件的装夹·····························································15

4.1对专用夹具的基本要求·······················································15

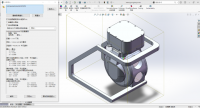

4.2定位方式的确定与定位组件的选择·············································15

4.2.1定位方式的确定···························································15

4.2.2定位组件的选择···························································15

第五章 数控加工·······························································20

5.1系统介绍···································································20

5.2程序指令的介绍·····························································20

5.2.1 M00、M01、M02和M30的区别与联系··········································20

5.2.2 G92与G54~G59的应用·····················································20

5.2.3暂停指令·································································21

5.3编写程序···································································21

5.3.1底平面加工程序···························································21

5.3.2轴承孔的加工程序·························································22

第六章 毕业设计的结果························································23

第七章 总结··································································24

参考文献······································································25

致谢··········································································26

Application of contorl system on the base of PLC in sewage treatment····················VIII

基于PLC的控制系统在污水处理中的应用········································XIV

参考文献

1.张新义. 经济型数控机床系统设计.机械工业出版社 ,1994

2.张建民.机电一体化系统设计 .高等教育出版社 ,2009(3)

3.叶伯生,朱志红,熊清平.计算机数控系统原理、编程与操作.华中理工大学出版社,1999

4.陈汝全等.微机工业控制.西安电子科技大学出版社,1996

5.刘书华.数控机床与编程.机械工业出版社,2007

6.张德全,陈思夫,林彬.机械制造装备及其设计.天津大学出版社,2003

7.范云涨,陈兆年.金属切削机床设计简明手册.机械工业出版社,1994

8.郭朝勇. AutoCAD2006(中文版)机械绘图基础与范例教程.清华大学出版社,2006(1)

9.兰建设.机械制造工艺与夹具.机械工业出版社, 2006

10.陆剑中.金属切削原理与刀具.机械工业出版社

11.刘春廷.材料力学性能.化学工业出版社,2009