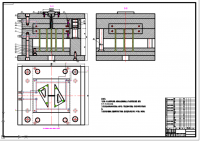

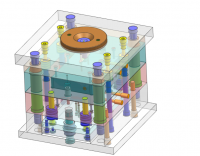

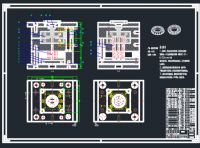

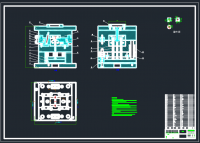

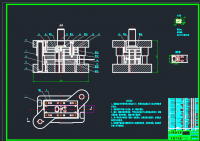

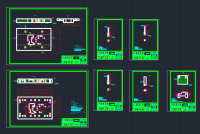

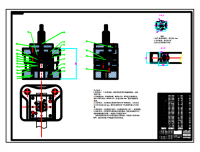

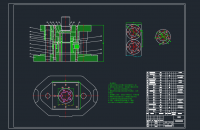

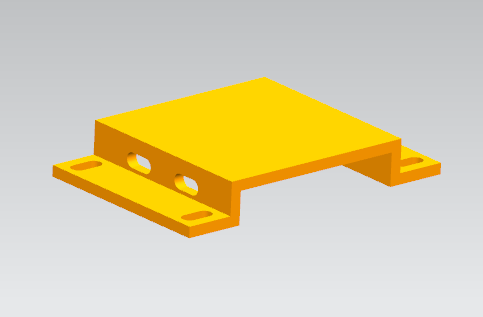

(模具毕业设计)键盘槽塑料模设计

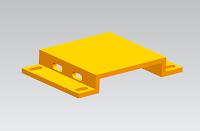

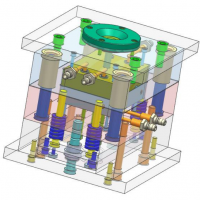

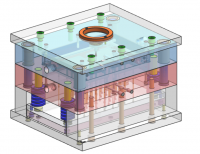

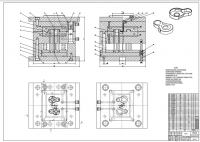

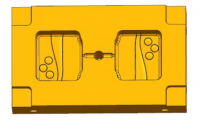

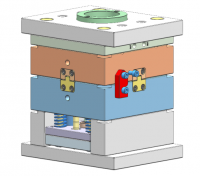

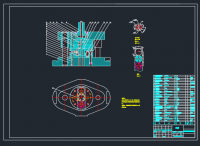

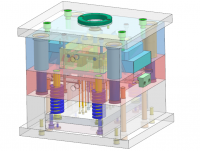

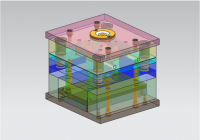

摘要:本次毕业设计的课题为键盘槽塑料模设计,主要在对塑件成型工艺分析的基础上从几何形状的分析、成型特性分析、结构工艺性分析、分型面的选择、成型零件的结构确定、推出机构设计、冷却系统设计、侧向分型与抽芯机构设计、导向机构设计和复位机构设计等方面详细的阐述了键盘槽塑料模的设计过程。同时也通过对注塑机注射压力、最大注射量、锁模力、模板的最大安装尺寸的校核等方面的考虑完成了对注射机的选择,进一步保证了设计的可靠性,并设计了温度调节系统。本课题的最大特点是采用弯销的侧向分型抽芯机构,使设计的模具结构更加合理,使用更加方便,加工更加便利,生产更加方便。

当然,在设计的过程中,我也查阅了大量资料、标准、手册、书籍,结合教材上的知识也对注射模具的组成(导向机构、推出机构,复位机构、冷却系统设计)有了较详细的认识,增长了知识,增加了阅历,为以后的工作积累了宝贵的经验。

关键词:键盘槽塑料模;侧向抽芯;推出机构;导向机构

Keyboard plastic tank design

Abstract: This graduation project topic for the keyboard plastic tank design, analysis, mainly on the basis of the plastic molding process from the analysis of the geometry, molding characteristics analysis, structural analysis process, select the parting surface of the molded part structure determination, Release mechanism design, cooling system design, side parting and core pulling mechanism design, guide mechanism design and reset mechanism design and other aspects in detail keyboard groove plastic mold design process. But also through the injection molding machine injection pressure, consider the maximum amount of injection, clamping force, the maximum dimensions of the template checking other aspects of the completion of the injection machine of choice, to further ensure the reliability of the design, and the design of the temperature adjustment system. Most important feature of this project is the use of bent pin side parting pulling mechanism so that the design of the mold structure is more reasonable and easier to use, more convenient processing, production and more convenient.

Of course, in the design process, I have access to a wealth of information, standards, manuals, books, materials on the combined knowledge also injection mold composition (guide mechanism Release mechanism, reset mechanism, cooling system design) with a more detailed awareness, increased knowledge, increased experience for future work accumulated valuable experience.

Keywords: keyboard plastic tank; side core; Release mechanism; guide means

目录

绪论.........................................................................................................................................................5

模具在加工工业中的地位................................................................................................................5

一、塑件成型工艺分析.....................................................................................................................6

1.塑件的几何形状分析.....................................................................................................................6

2.塑件原材料的成型特性分析.......................................................................................................6

3.塑件的结构工艺性分析.................................................................................................................7

3.1塑件的尺寸精度分析..........................................................................................................7

3.2塑件的表面质量分析..........................................................................................................7

3.3塑件的结构工艺性分析......................................................................................................7

4.塑件的生产批量................................................................................................................................7

5.初选注射机.........................................................................................................................................8

5.1计算塑件的体积或重量...........................8

5.2根据塑件的本身的几何形状及生产批量确定型腔的数目......................................8

5.3确定注射成型的工艺参数..................................................................................................8

5.4确定模具温度及冷却方式..................................................................................................8

5.5确定成型设备.........................................................................................................................8

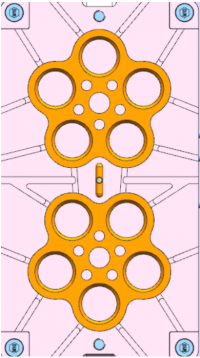

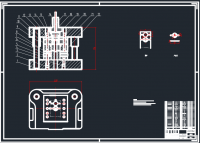

二、分型面及浇注系统的设计........................................................................................................10

1.分型面的选择....................................................................................................................................10

2.浇注系统的设计...............................................................................................................................10

2.1主流道和定位圈的设计......................................................................................................11

2.2分流道的设计........................................................................................................................11

2.3浇口的设计.............................................................................................................................12.

三、键盘槽的结构设计......................................................................................................................13

1.型腔的布置.........................................................................................................................................13

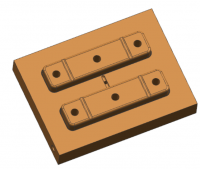

2.成型零件的结构设计.......................................................................................................................13

2.1型腔的设计..............................................................................................................................13

2.2型芯的设计..............................................................................................................................13

3.推出机构的设计................................................................................................................................13

4.抽芯机构的确定................................................................................................................................13

5.冷却系统的设计..............................................................................................................................14

四、主要零部件的设计计算..............................................................................................................15

1.成型零件的成型尺寸.......................................................................................................................15

2.模具型腔壁厚的设计.......................................................................................................................18

2.1型腔侧壁厚度S的计算.........................................................................................................18

2.2型腔底板厚度T的计算.........................................................................................................19

3.抽芯机构的设计与计算...................................................................................................................19

3.1抽芯距s的计算.......................................................................................................................19

3.2抽芯力的计算.........................................................................................................................20

3.3确定斜顶的倾斜角................................................................................................................20

3.4确定斜顶的顶出距离和抽芯距离....................................................................................20

3.5确定楔紧块...............................................................................................................................20

4.推出机构的设计.................................................................................................................................20

5.标准模架选择......................................................................................................................................20

五、成型设备的校核.............................................................................................................................21

1.锁模力的校核......................................................................................................................................21

2.安装尺寸的校核..................................................................................................................................21

3.推出机构的校核..................................................................................................................................21

4.开模行程的校核..................................................................................................................................21

回顾总结.....................................................................................................................................................23

致谢..............................................................................................................................................................25

参考文献....................................................................................................................................................26

参考文献

1.《塑料模成型工艺与模具设计》(第三版),主编 高汉华 何冰强,大连理工出版社

2.《塑料成型工艺学》,主编 黄锐,中国轻工业出版社

3.《模具设计与制造简明手册》,主编 冯炳尧 韩泰荣 殷振海 蒋文森,上海科学技术出版社

4.《材料成型设备》,主编 王卫卫,机械工业出版社

5.《塑料模具设计参考资料汇编》,主编 邹继强,清华大学出版社

6.《塑料模设计手册》,机械工业出版社

7.《塑料模设计指导》,主编 叶久新,北京理工大学出版社

8.《塑料成型工艺与模具设计》,主编 齐晓杰,机械工业出版社