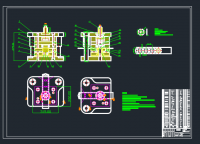

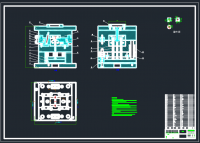

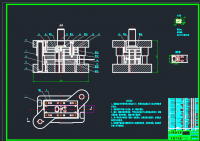

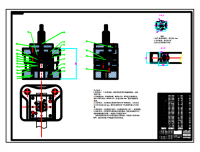

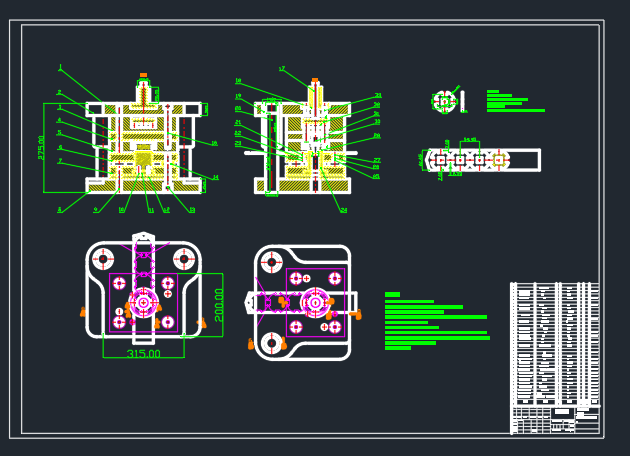

调节器附件 2 冲压模具设计

摘要

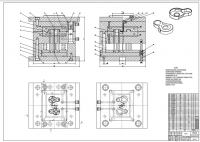

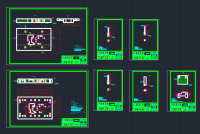

这次的说明书主要从以下几个方面进行论述。冲压变形中每个步骤的详细讲

解,冲裁部件尺寸的计算,凸模和凹模刃口尺寸计算,冲裁力大小,压力中心计

算,排样设计,整套模具的结构设计,推件装置的设计,成型零部件结构设计,

模具标准件的选用,选择合适的压力机等等。最后还要探讨下冲压模具经常出现

故障的问题点以及分析它的原因。这篇说明书中的每个篇章每个章节都是对自己

设计的冲压复合模具的详细讲解,在说明的时候还加入了图片和表格,丰富说明

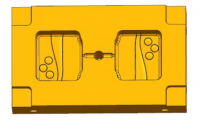

内容,加强说服力,是整片文章更有亮点和看点。这次的产品是调节器附件二,

是机械装备上的零部件,猜想是通过安装它来调节整体的厚度和高度的。所以外

形尺寸很重要,太大了会卡住装不进去,太小了会松弛在机器工作过程中会不稳

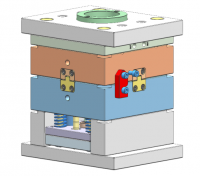

定,左右晃动,时间长了甚至起到了消极的影响。这次设计的是冲压复合模具,

是冲压模具类型中较为常用的,能够保证产品形状之间的相对位置的尺寸达到要

求,成本比级进模低,精度比单工序冲压模具高。

关键词:调节器附件二,冲压复合模具

第一章褚论

1.1 冲压工艺介绍

冲压加工是改变金属产品形状的加工方法,是利用安装在压力机上的模具对

板材施加压力,在常温下改变其形状或分离的一种加工方法。产品具有尺寸精度

高,形状完整,生产效率高的特点。在机械加工中是一种高效率的加工方式。最

常见的是将一个平面的金属板变成立体的,冲压产品广泛的用于各个行业中,大

到航空航天,军事科技,轮船火箭,小到医疗器械,食用的餐具,量具内的零件。

都要用到冲压加工,所以在生活中无处不在,随处可见。

冲压工艺有以下几个特点:1.冲压件表面不粗糙,质量轻,强度好。2.能生

产复杂的产品,具有其他加工设备在绩效比上没法比拟的优势,像这样小型的产

品,一分钟可以生产四五个。3.模具制造精度高,冲压件质量稳定,尺寸符合精

度要求,所以冲压件质量过关,互换性强。4.材料利用率高,一般要在 50%以上

5.操作简单,经过短期培训后的工人可以上岗任职。现在传送料带的装置用的自

动送料的比较多,易于实现机械化和自动化生产。6.对于冲压模具设计师的要求

较高,一副模具的好坏的源头在于设计,设计者要有理论和实践相结合的检验,

要有很强的想象力和与创造力。 7.小批量且要求交货时间急促的产品不适合冲压

模具生产,因为模具成本高,制造周期长。8.由于是滑块上下闭合运动来生产产

品,存在很大的安全风险,手工操作时劳动强度大,

目录 摘要·································································································3

第一章褚论························································································4

1.1 冲压工艺介绍··········································································4

1.2 冲压模具的发展历程·································································5

第二章冲裁工艺方法············································································6

2.1 材料分析················································································6

2.2 冲裁件精度分析·······································································6

2.3 冲裁方案比较··········································································7

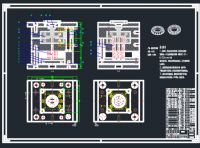

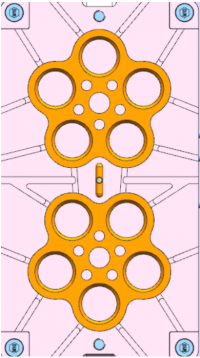

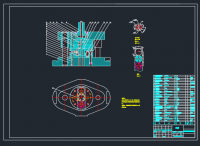

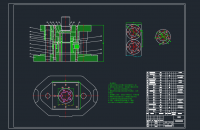

第三章产品的排样···············································································8

3.1 排样的方法·············································································8

3.2 搭边值的确定··········································································9

3.3 排样方案比较·········································································10

第四章确定冲裁间隙··········································································12

4.1 冲裁间隙的简述······································································12

4.2 冲裁间隙对于冲压的影响························································· 12

4.3 选择合理的间隙值···································································13

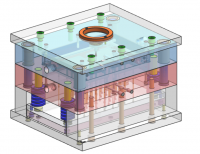

第五章成型零件设计··········································································14

5.1 冲压模具成型零件定义···························································· 14

5.2 成型零件的刃口尺寸计算························································· 15

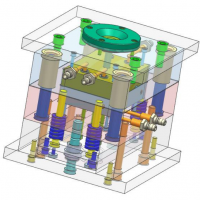

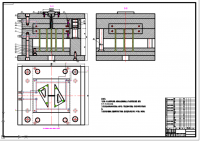

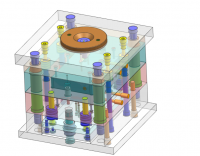

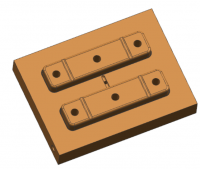

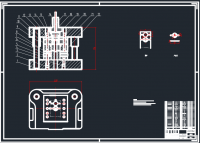

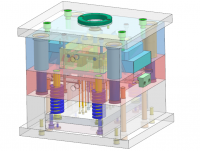

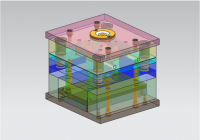

第六章 主要零件的设计······································································16

6.1 凸模设计···············································································16

6.2 凹模设计···············································································16

6.3 凸凹模设计············································································17

6.4 卸料板设计············································································18

6.5 挡料销和定位销设计································································19

6.6 推出装置设计·········································································19

6.7 固定板设计············································································20

6.8 选择合适的模架······································································22

第七章冲裁力和压力中心选择······························································22

7.1 冲裁力计算············································································22

7.2 压力中心计算·········································································22

第八章选择合适的压力机····································································23

8.1 压力机的工作原理···································································23

8.2 选择合适的压力机···································································23

第九章总结和展望·············································································25

9.1 总结·····················································································25 9.2

致谢·····················································································27

参考文献························································································· 27

参考文献

1.《冷冲模设计资料与指导》 主编 杨关全 匡余华 大连理工大学出版社

2.《冲压工艺与模具设计》 主编 成虹 高等教育出版社

3.《模具设计与制造实训教程》 主编 李学峰 化学工业出版社

4.《机械制图与零部件测绘》 主编 华红芳 电子工业出版社

5.《冲压模具设计实用手册》 主编 陈炎嗣 化学工业出版社