6Cr13冷轧不锈钢带退火工艺

摘要:6Cr13冷轧不锈钢带,冷轧过程中要求硬度值≤201HB,因冷轧过程中产生硬化,为使得到更薄的钢带,需安排中间退火,故从退火工艺展开分析,查找影响6Cr13冷轧不锈钢带软化的重要性能指标。研究结果对6Cr13冷轧不锈钢带退火工艺设计具有指导意义。

关键字:6Cr13不锈钢带;冷轧;退火工艺

Annealing process design of 6Cr13 cold rolled stainless steel strip

The hardness value of 6Cr13 cold rolled stainless steel strip is required to be less than 201hb during cold rolling. Due to the hardening during cold rolling, intermediate annealing is required to get thinner strip. Therefore, the annealing process is analyzed to find out the important performance indexes affecting the softening of 6Cr13 cold rolled stainless steel strip. The research results have guiding significance for annealing process design of 6Cr13 cold rolled stainless steel strip.

目录

1 .概述 4

1.1课题来历 4

1.2刀片材料性能及要求 5

1.3 6Cr13冷轧不锈钢带的生产工艺 7

2. 6Cr13冷轧不锈钢带退火工艺设计 10

2.1 6Cr13冷轧不锈钢带退火的目的 10

2.2 6Cr13冷轧不锈钢带退火方法的选择 11

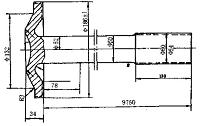

3.6Cr13冷轧不锈钢带退火设备的确定 12

3.1炉内气氛的选择 12

3.2加热炉类型选择 13

3.3炉体结构选择 15

3.4热处理冷却方式 16

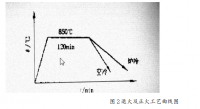

4.6Cr13冷轧不锈钢带中间退火热处理工艺参数 18

4.1 热处理一般工艺 18

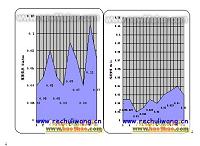

4.2 6Cr13不锈钢再结晶退火工艺参数 20

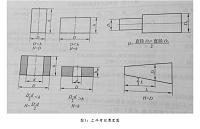

5.热处理工艺卡 23

6.结论 23

7.参考文献 24

参考文献

[1] 杨满,刘朝雷.热处理参考手册第二版[M]北京:机械工业出版社,2020.

[2] 王忠诚.热处理实用手册[M]北京:机械工业出版社,2012.

[3]薄鑫涛,郭海祥,袁凤松。上海市热处理协会[M]上海:上海科技技术出版社,2009

[4]樊东黎. [M]北京化学工业出版社,2009

[5]焦何生.5CrNiMo铜齿轮热锻模具的热处理工艺研究 [J] 金属加工,2021

[6]袁钰坤,葛莉娜,张鹏博,朱伟强,郭刚.T250马氏体时效钢晶粒细化热处理[J]金属热处理2021

[7]樊东黎,徐跃明,佟晓辉[M]北京:机械工业出版社,2011