壳体铣两侧面工装设计

摘要:在生产过程中,使生产对象(原材料,毛坯,零件或总成等)的质和量的状态发生直接变化的过程叫工艺过程,如毛坯制造,机械加工,热处理,装配等都称之为工艺过程。在制定工艺过程中,要确定各工序的安装工位和该工序需要的工步,加工该工序的机车及机床的进给量,切削深度,主轴转速和切削速度,该工序的夹具,刀具及量具,还有走刀次数和走刀长度,最后计算该工序的基本时间,辅助时间和工作地服务时间。

关键词: 工序;工艺;定位方案

Design of shell side milling industry

Abstract:Enable producing the target in process of production (raw materials, the blank , state of quality and quantity on part become always ) take place direct course of change ask craft course, if the blank is made, machining, heat treatment , assemble etc. and call it the craft course. In the course of making the craft , is it confirm every erector location and worker step that process need this of process to want, the locomotive of processing , this process , and the entering the giving amount of the lathe, cut depth , the rotational speed of the main shaft and speed of cutting, the jig of this process, the cutter and measuring tool, a one hundred sheets of number of times still leaves and a one hundred sheets of length leaves, calculate basic time of this process , auxiliary time and service time of place of working finally.

Keywords: The process;worker one ;orient the scheme

目录.....................................................................................................................................2

第一章 序言...................................................................................................................4

1.1选题的意义....................................................................................................................5

1.2夹具的发展方向............................................................................................................6

1.3本章小结........................................................................................................................6

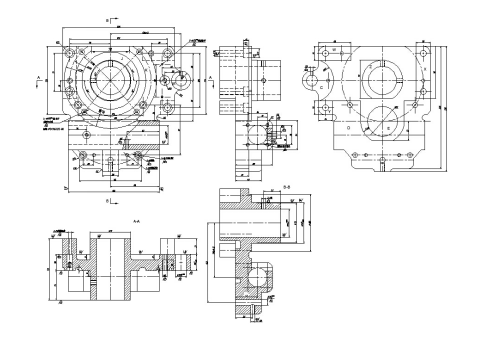

第二章 壳体的加工工艺规程设计.........................................................................6

2.1壳体的工艺....................................................................................................................6

2.1.1壳体的作用................................................................................................................6

2.1.2壳体的技术要求.........................................................................................................8

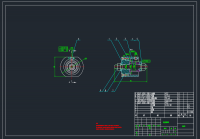

2.1.3壳体的工艺分析.........................................................................................................8

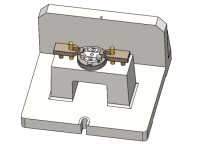

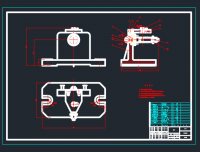

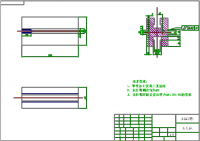

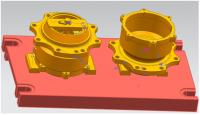

2.3确定毛坯,绘制毛坯简图.............................................................................................9

2.3.1选择毛坯.....................................................................................................................9

2.3.2绘制壳体毛坯的铸造简图.......................................................................................10

2.4拟定壳体工艺路线.......................................................................................................10

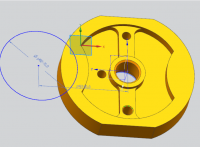

2.4.1定位基准的选择.......................................................................................................10

2.4.2精基准的选择...........................................................................................................11

2.4.3粗基准的选择...........................................................................................................11

2.5各面、孔加工方法的确定............................................................................................11

2.6加工阶段的划分...........................................................................................................11

2.7工序的集中于分散.......................................................................................................12

2.8工序顺序的安排...........................................................................................................12

2.8.1机械加工工序...........................................................................................................12

2.8.2热处理工序...............................................................................................................12

2.8.3辅助工序...................................................................................................................13

第三章 机床设备及工艺装备的选用..................................................................13

3.1机床设备的选用..........................................................................................................13

3.2工艺装备的选用..........................................................................................................14

第四章 加工余量、工序尺寸和公差的选用.....................................................14

第五章 切削用量与时间定额的计算..................................................................14

5.1切削用量的计算..........................................................................................................15

5.1.1钻孔工步...................................................................................................................15

5.1.2粗绞工步...................................................................................................................16

5.1.3精绞工步...................................................................................................................16

5.2时间定额的计算...........................................................................................................16

5.2.1基本时间Tj的计算.................................................................................................16

5.2.2辅助时间Tf的计算.................................................................................................17

5.2.3其他时间的计算.......................................................................................................17

5.2.4单件时间Tdj的计算...............................................................................................17

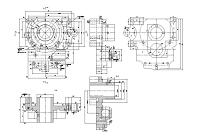

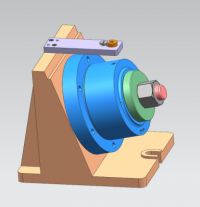

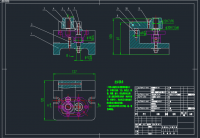

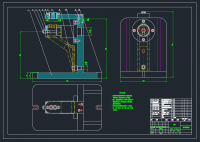

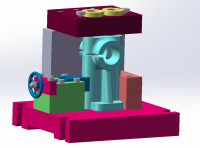

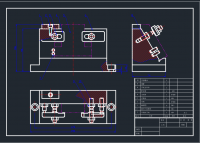

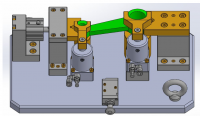

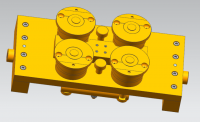

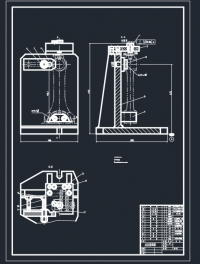

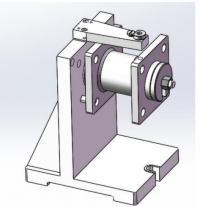

第六章 夹具设计........................................................................................................17

6.1问题的提出...................................................................................................................18

6.2定位方案.......................................................................................................................18

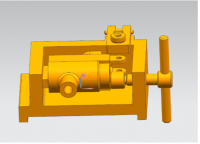

6.3夹紧机构.......................................................................................................................18

6.4夹具与机床的联接元件...............................................................................................19

6.5定位误差分析...............................................................................................................19

6.6切削力及夹紧力的计算...............................................................................................19

第七章 结论.................................................................................................................20

致谢....................................................................................................................................21

参考文献..........................................................................................................................22

参考文献

[1] 石彦国,任莉.大豆制品工艺学【M】.天津:机械工业出版社,2006 35~

[2] 李庆寿机床夹具设计( ),北京:机械工业出版社,1983 86~97

[3] 王笑天.金属材料学(M).北京:机械工业出版社,1987 22~36

[4] 邱中怀.技术,应用与开发EM).北京:机械工业出版社,2002 33~65

[5] 张华. 机械原理(M).北京:高等教育出版社,1999:40~55

[6] 东北重型机械学院.洛阳工学院,第一汽车制造厂职工大学, 机床夹具设计手册【M】,上海:. 上海科学技术出版社,1988:103~121

[7] MATLAB6.5应用接口编程,电子工业出版社,北京,2003:56~74

[8] 王平鸿.机器维修工程学(M).北京:农业出版社,1990:19~39

[9] 张耀鹅.加工技术实用手册(M).北京:冶金工业出版社,2007:120~146

[10] 孙宝珍.合金钢手册.北京:兵器工业出版社,1992:36~58

[11] 李伊敏.和辩工艺设计工作的要求。机械工业出版社,1993:36~58

[12] 姚晨。实际加工工艺设计手册。航空工业出版社,1999; 120~146

[20] Hirohiko Arai, Kazuo Tanie, and Susumu Tachi. Dynamic Control of a Manipulator with Passive Joints in Operational Space

http://www.bysj1.com/ http://www.bysj1.com/html/4775.html http://www.bysj1.com/html/5200.html