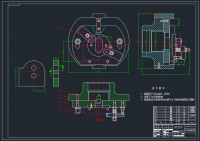

(工艺夹具毕业设计))基于奥迪汽车发动机连杆铣扩夹具设计

摘 要:

Abstract:

随着机械加工行业的快速发展,以提高加工效率的提高和劳动强度越来越高,为各种复杂的结构工件的结构,普通机床夹具已不能满足加工要求。

With the rapid development of mechanical processing industry, to improve the machining efficiency is improved and the labor intensity has been getting higher and higher, for a variety of complex structure of the workpiece, ordinary machine tool fixture has been unable to meet the processing requirements.

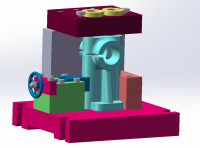

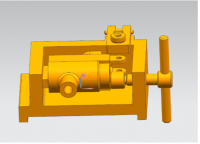

因此,结合现状,以适应某一部分的加工过程,对专业设计和制造的特殊夹具应运而生,设计是连杆式轧机的专用夹具。

Therefore combined with the status quo in order to adapt to a certain part of a process of processing the requirements of the specialized design and manufacture of special fixtures came into being, this design is a special fixture for connecting rod mill.

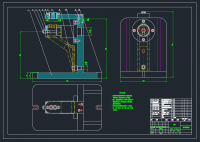

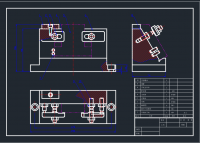

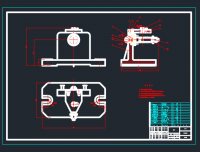

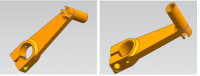

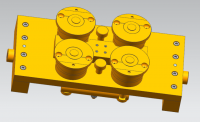

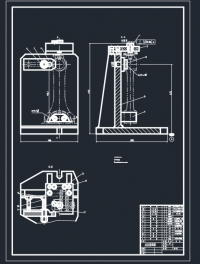

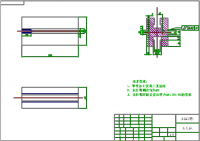

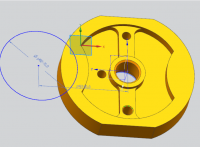

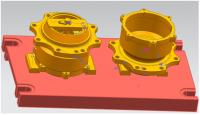

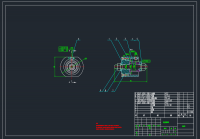

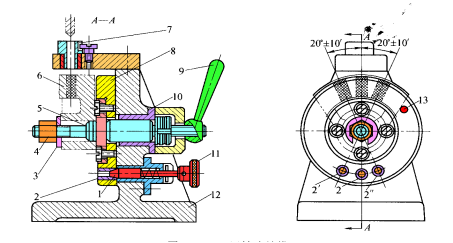

根据连杆的结构特点,采用了“一面两孔”的定位方案,以支撑板和圆柱销,切边销为定位元件,使工件安装方便,可保证加工精度。

According to the structure characteristics of the connecting rod, the positioning scheme of "one side two holes" is adopted to support the plate and the cylindrical pin, and the cutting edge pin is the positioning element, so that the workpiece is convenient to be installed, and the machining precision can be ensured.

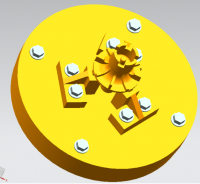

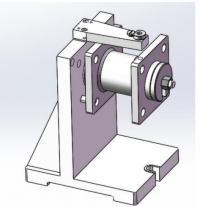

以杠杆原理为核心,双压板工件。同时,联动机制,左边滚筒按正确的自动压。参考液压系统用于夹紧电源,降低了工人的劳动强度。

With the lever principle as the core, the double - clamp piece work, simultaneously, the linkage mechanism, the left drum presses the correct automatic pressure. The reference hydraulic system used for clamping the power source, reduced the labor intensity of the worker.

连杆的尺寸精度、形状精度和位置精度要求很高,连接杆的刚度差,容易变形,所以在这个过程中,你需要把粗精加工过程中的主要表面分开。逐步减少加工余量,切削力和内力,并修正加工后的变形一个最终实现零件的技术要求。

Linkage of the dimensional accuracy, shape accuracy and position accuracy requirements are very high, and the rigidity of the connecting rod is poor, easy to deform, so in the process, you need to separate the main surface of the coarse and fine machining process. Gradually reduce the machining allowance, cutting force and internal force and correction the deformation after processing, you can finally achieve the technical requirements of the parts.

关键词:连杆;变形;夹具设计;定位;夹紧;液压

Key words: connecting rod, deformation, fixture design, positioning, clamping, hydraulic

目录

第一章 绪论 1

1.1课题选择的意义 2

1.2课题的研究内容 2

1.3论文的结构和内容 2

第二章 夹具的具体结构设计 3

2.1 问题提出 3

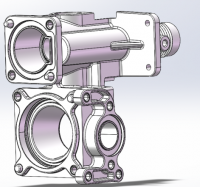

2.2 机床夹具 3

2.2.1机床夹具设计的基本要求 3

2.2.2机床夹具设计的一般步骤 4

2.3 夹具设计的标准 10

2.3.1 定位基准选择 10

2.3.2 自由度分析 10

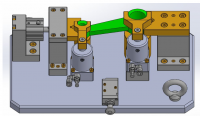

2.3.3 确定夹紧方案、设计夹紧机构 11

2.3.4 切削力及夹紧力的计算 12

2.3.5 定位误差分析 13

第三章 奥迪汽车发动机连杆 15

3.1 奥迪汽车发动机 15

3.1.1.可变长度进气歧管 15

3.1.2.可变进气相位 15

3.1.3.涡轮增压技术 16

3.1.4.FSI燃油直喷 16

3.1.5.AVS-奥迪可变气门升程 17

3.1.6.竞品分析 17

3.1.7.废气再循环系统(EGR) 17

3.1.8.二次空气喷射(SAIS) 18

3.2 发动机定义 18

3.3 发动机结构参数 18

3.3.1.结构参数 19

3.3.2.发动机主要性能指标 19

3.4 连杆专用夹具设计 19

3.5 连杆的功用和结构特点 21

3.6 主要加工面和技术要求 22

3.7连杆的材料和毛坯 23

3.8连杆的机械加工工艺过程 23

3.9基准的选择 24

3.9.1 粗基准的选择 24

3.9.2 精基准的选择 26

第四章 总结与展望 29

结论 29

致谢与发展 29

参考文献 30

附录 31

英文翻译 31

参考文献

1.倪森寿 《机械制造工艺与装备》 北京工业出版社 2009

2.陈桂芬 孙燕华 《机械制图》 电子工厂出版社 2013

3.刘建武 《机电专业英语》 西安交通大学出版社 2014

4.倪森寿 《机械技术基础》 人民邮电出版社 2009

5.张豪 《机电一体化设备维修》 化学工业出版社 2010

6.倪森