后盖旋钮注塑模设计

摘 要

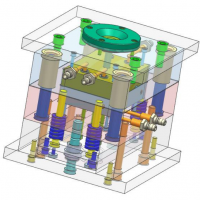

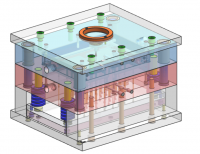

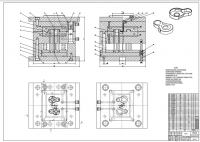

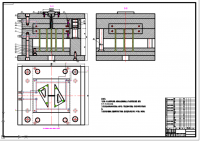

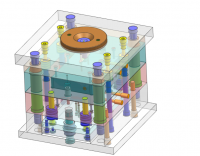

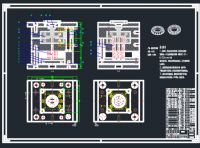

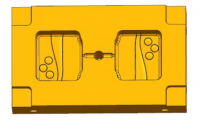

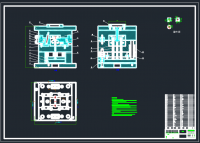

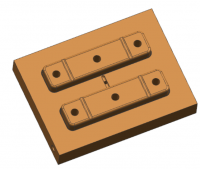

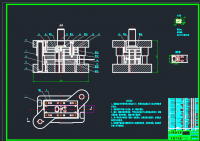

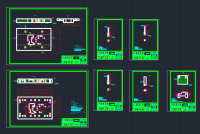

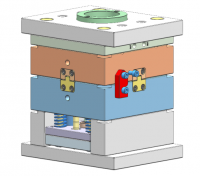

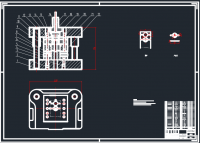

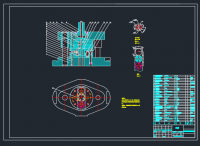

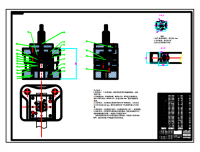

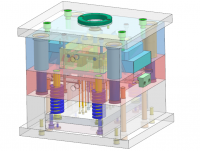

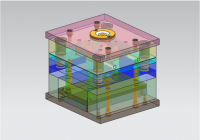

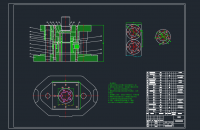

根据塑料制品的要求,了解塑件的用途,分析塑件的工艺性、尺寸精度等技术要求,考量塑件制件尺寸。本模具采用一模两腔,侧浇口进料,注射机采用TOSHIBA EC40-Y型号,设置冷却系统,CAD绘制二维总装图和零件图,选择模具合理的加工方法。附上说明书,系统地运用简要的文字,简明的示意图和和计算等分析塑件,从而作出合理的模具设计。

关键词:机械设计;模具设计;CAD绘制二维图。

Abstract

To understand the use of plastic parts in accordance with the requirements of the plastic products, analysis of the technical requirements of the plastic parts of the process, dimensional accuracy, select the workpiece size of the plastic parts. The mold using a two sub gate feed injection machine adopts TOSHIBA the EC40-Y models, and set a cooling system, CAD drawing two-dimensional assembly diagram and parts diagram, reasonable mold processing methods. Attach a manual, use brief text, a concise diagram and calculated analysis of plastic parts, in order to make a reasonable mold design.

Keywords: mechanical design; mold design; CAD drawing two-dimensional map; injection machine selection.

目录

摘要 ····························································1

Abstract ·························································· 2

第一章序言·················································· 3

第二章塑件工艺分析···········································4

2.1 塑件成型工艺分析·········································4

2.2 后盖旋钮原料的成型特性与工艺参数························ 5

第三章注塑设备的选择··········································7

3.1 估算塑件体积 ·············································7

3.2 选择注塑机 ··············································7

第四章型腔数的确定及浇注系统的设计 ··························10

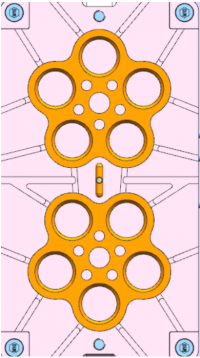

4.1 分型面的选择 ············································10

4.2 型腔数的确定 ············································10

第五章浇注系统的设计 ········································12

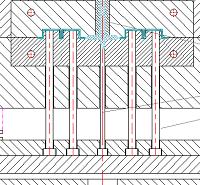

5.1 主流道的设计·············································12

5.2 冷料穴与拉料杆的设计····································12

5.3 分流道的设计 ············································13

5.4 浇口的设计··············································13

第六章冷却系统的设计与计算 ··································14

6.1 冷却水道设计的要点 ······································14

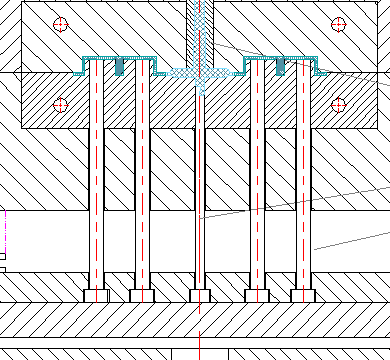

6.2 冷却水道在定模和动模中的位置 ····························15

第七章模具工作零件的设计与计算·······························16

7.1 型腔型芯工作尺寸的计算···································16

7.2 模具强度与刚度校核 ·····································18

第八章脱模及推出机构的设计与计算·····························19

8.1 脱模力的计算 ············································ 19

8.2 推出机构的设计···········································19

结论 ····························································22

小结 ···························································23

致谢 ····························································24

参考文献 ························································25

参考文献

[1]陈孝康,周兴隆.实用模具技术手册[M].北京:中国轻工业出版社,2001.

[2]彭建生.模具设计与加工速查手册[M].北京:机械工业出版社,2005.

[3]申开智.塑料成型模具[M].北京:中国轻工业出版社,2002.

[4]刘守勇.机械制造工艺与机床夹具[M].北京:机械工业出版社,2000.

[5]张铮.模具制造技术[M] .北京:电子工业出版社,2002.

[6]丁闻.实用塑料成型模具设计手册[M].西安:西安交通大学出版社,1993.

[7]李志刚,夏巨谌.中国模具设计大典[M].中国机械工程学会,2003.

[8]潘宝权.模具制造工艺[M].北京:机械工业出版社,2004.

[9]李益民.机械制造工艺设计简明手册[M].北京:机械工业出版社,1993.

[10]李云程.模具制造技术[M].北京:机械工业出版社,2002.

[11]刘彦国,严慧萍.注塑成型模腔数量的择优确定[J].电加工与模,2006.

http://www.bysj1.com/ http://www.bysj1.com/html/3515.html http://www.bysj1.com/html/1146.html