玻璃粉烧结金刚石砂轮研制及磨削加工实验研究

摘 要

金刚石是具有诸多优异性能的极限材料,广泛用于工业、科技、国防、医疗卫生等领域。掺玻璃粉金刚石具有诸多优良的性质,比普通金刚石显示出更优异的性能,因而成为当前金刚石掺杂中的研究热点。

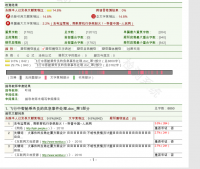

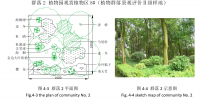

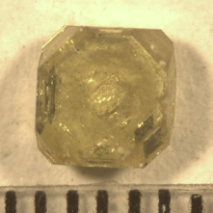

本文是通过将一定比例的玻璃粉粉均匀的加入到金刚石合成体系中,在六面顶压机上利用高温高压方法合成掺玻璃粉金刚石。实验通过设置掺玻璃粉梯度,研究了不同含量的玻璃粉对金刚石合成的影响。实验分为两个部分进行研究:(1)实验摸索阶段:通过合成不掺加玻璃粉的金刚石确定实验条件,最终确定实验条件为,压力:74.5Mpa,晶床和堵头尺寸:6mm和7mm;(2)掺玻璃粉金刚石合成阶段:在第一阶段设置的实验条件下,将不同比例的玻璃粉粉掺入金刚石合成体系中,合成金刚石。通过研究发现:随着系统中的玻璃粉含量的增加,金刚石晶体的颜色开始逐渐发生变化,由黄色逐渐变为暗黄和黑色。同时随着含玻璃粉量的增加,晶体的尺寸和完整度减少,而且晶体表面上的凹坑越来越严重,并且晶体中包裹体含量增加,并由弥散状逐渐增加到贯穿整个晶体内部。通过对掺玻璃粉和未掺玻璃粉的金刚石拉曼图谱进行对比,我们得出在误差允许的范围内拉曼峰和半高宽都基本在很小范围内波动,金刚石拉曼峰基本没有变化。

关键字:金刚石;高温高压;玻璃粉掺杂。

Abstract

Diamond is the ultimate material has many excellent properties, is widely used in industry, science and technology, national defense, medical and health fields. Sulfur doped diamond has many excellent properties, than ordinary diamond shows more excellent performance, has become the current research focus of doping of diamond.

This paper is sulfur powder through a certain proportion of the evenly added to the diamond synthetic system, synthesis of sulfur doped diamond by using high temperature and high pressure in the six cubic press. The experiment by setting the sulfur doping gradient, the effects of different content of sulfur in diamond synthesis. The experiment was divided into two parts: (1) experiment fumble stage: the experimental conditions were determined by synthesis without addition of sulfur diamond, ultimately determine the experimental conditions, pressure: 74.5Mpa, crystal bed and plug size: 6mm and 7mm; (2) sulfur doped diamond synthesis stage: the first stage setting next, the sulfur powder by adding different proportion into diamond synthesis system,synthetic diamond. Through the study found that: with the increase of sulfur content in the system, the color of diamond crystals gradually began to change, gradually change from yellow to dark yellow and black. At the same time with the increase of sulfur content, size and the integrity of the crystal is reduced, and pits on the surface of crystal is more and more serious,and inclusions in the crystal content increased, and the scattered gradually increased to run through the whole crystal.Through comparison of diamond Raman spectra of sulfur doped and undoped sulfur, we draw in the tolerance of the Raman peaks and FWHM are basic varies in a small range, the diamond Raman peak basically no change.

Keywords: diamond; high temperature and high pressure;sulfur-doped.

目 录

第一章 绪论 1

1.1 金刚石简介 1

1.1.1 金刚石的组成 1

1.1.2 金刚石的结构 2

1.1.3金刚石的性质和用途 3

1.1.4 金刚石的分类 5

1.1.5 金刚石的成因 6

1.2 金刚石的开发简史和研究现状 6

1.2.1 金刚石的开发简史 6

1.2.2 金刚石的研究现状 7

1.3 选题意义以及主要研究内容 8

第二章 玻璃粉烧结金刚石砂轮研制 10

2.1 金刚石的生长规律 10

2.1.1 金刚石生长的一般规律 10

2.1.2 影响金刚石晶体生长速度的主要因素 11

2.1.3 金刚石生长速度的分区及分析 12

2.2 金刚石合成技术 14

2.2.1 高温高压技术 14

2.2.2 温度梯度法 14

2.3 合成实验的精密化控制 17

2.3.1 压力控制 17

2.3.2 温度控制与功率控制 18

第三章 磨削加工实验研究 20

3.1 原材料 20

3.1.1 传压介质——叶蜡石和白云石 20

3.1.2 石墨 22

3.1.3 触媒 22

3.1.4 氯化钠 22

3.1.5 材料加工 23

3.2 实验设备介绍 24

3.3实验组装 27

3.3.1 白云石衬管叶蜡石块 27

3.3.2 导电钢帽(堵头) 28

3.3.3 辅助热源 29

3.3.4 核心结构 29

3.3.5实验组装的确定 29

第四章 掺玻璃粉金刚石的合成 32

4.1玻璃粉的性质和成键特点 32

4.2玻璃粉的结构 32

4.3 实验条件的确定 33

4.3.1 触媒的选择 33

4.3.2 实验压力的确定 33

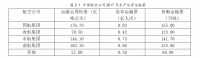

4.4实验结果与分析 34

4.4.1 合成温度 34

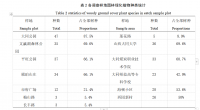

4.4.2 添加剂玻璃粉对金刚石形貌影响 36

4.4.3 掺玻璃粉体系金刚石的拉曼光谱测试 39

4.4.4 实验问题分析 41

第五章 结论 43

致 谢 44

参考文献 45

参考文献

[1] H. Kanda and T. Ohsawa.Effect of solvent metals upon the morphology

of synthetic diamonds [J].Journal of Crystal Growth, 1989,94: 115-124;

[2] 芶清泉,《人造金刚石合成机理研究》,成都科技大学出版社,1986

年;

[3] L.J. Giling and W.J.P. Van Enckevort.On the influence of surface

reconstruction on crystal growth processes[J].Surface Science, 1985,161: 567-583;

[4] S.Yamaoka, H. Komatsu, H. Kanda and N. Setaka.Growth of diamond

with rhombic dodecahedral faces[J] J. Crystal Growth, 1977,37: 349-352;

[5] H. Sumiya, S. Satoh, Y. Nishibayashi, Y. Goda, “Development of

high-purity synthetic diamonds”, Sumitomo Electric Technical Review, number

39, January 1995, p. 69;

[6] 方啸虎.中国超硬材料新技术与进展.中国科学技术大学出版

社.2003;

[7] 周东晨.赵国权.金刚石合成工艺.机械工业出版社.1998;

[8] J.E. Shigley, E. Fritsch, C.M. Stockton, J.I. Koivula, C.W. Fryer and

R.E. Kane[J]Gems &Gemmol, 1986,22-4:192;

[9] H. Sumiya, N. Toda and S. Satoh , High-quality large diamond

crystals[J] New Diamond and Frontier Carbon Technology, 2000,10: 233;

[10] F.P. Bundy, H.P. Bovenkerk, H.M. Strong, and R.H. Wentorf, Jr.,

Diamond-graphite equilibrium line from growth and graphitization of diamond[J]

J. Chem. Phys., 1961,35: 383-391;

[11] C.S. Yan, H.K. Mao, W. Li, J. Qian, Y. Zhao, and R.J. Hemley,

Ultrahard diamond single crystals from chemical vapor deposition[J], Physica

Status Solidi A, 2004,201: R24-R27.;

[12] M. Wakatsuki and K. Takano, Suppression of spontaneous nucleation

and seeded growth of diamond [M] High-Pressure Research in Mineral Physics,

edited by M.H. Manghnani and Y. Syono, 1987: 203-207;

[13] H. M. Strong and R. E. Hanneman, Crystallization of diamond and

graphite[J] J. Chem. Phys., 196746: 3668;

[14] F.P. Bundy, Direct conversion of graphite to diamond in static pressure

apparatus[J] J. Chem. Phys., 1963,38: 631;

[15] S. Naka, K. Horii, Y. Takeda, T. Hanawa, Direct conversion of graphite

to diamond under static pressure[J] Nature, 1976,259: 38;

[16] H. Sumiya, N. Toda, S. Satoh, Development of high-purity large-size

synthetic diamond crystals[J] Sumitomo Electric Technical Review, 2005,60: 10;

[17] T.R.Anthony, Stresses generated by impurities in diamond[J]

Diamond and Related Materials, 1995,4:1346-1352.20 F.P. Bundy,

Sverkhtverdye Materialy, 10(3)(1988) 3-9;

[18] R.C. Burns, S. Kessler, M. Sibanda, C.M. Welbourn, D.L. Welch,

“Large synthetic diamonds[M], Proc. 3rd NIRIM Int. Symp. Advanced Materials,

1996 105-111;

[19] A.R. Lang, M. Moore, A.P.W. Makepeace, W. Wierzchowski, C.M.

Welbourn, “On the dilatation of synthetic type Ib diamond by substitutional

nitrogen impurity”[J], Phil. Trans. R. Soc. Lond. A, 337 (1991) 497-520;

[20] 贾晓鹏,“宝石级金刚石的合成”,香山会议,2000年北京。

http://www.bysj1.com/ http://www.bysj1.com/html/5215.html http://www.bysj1.com