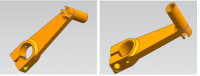

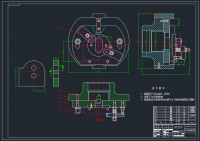

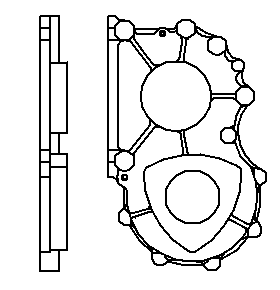

前端齿轮盖工艺及镗φ88孔夹具设计 (夹具毕业设计)

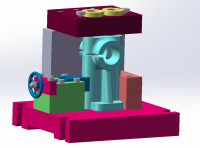

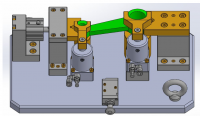

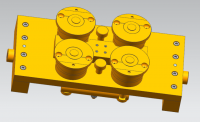

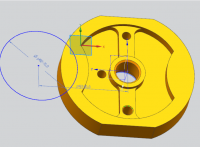

摘要:在机械加工零件时如果能广泛地使用夹具,就能极大地节省加工时的辅助时间,减轻工人的劳动量,提高产品的质量和劳动生产率。本文主要介绍了设计铣床夹具的的一般步骤和方法。设计夹具的一般先对原始资料进行分析,明确设计的要求和意图,然后提出具体的定位、夹紧、对刀方案和夹具体的一般结构。本文采用六点定位的定位方法,夹紧螺钉与双向压板组合的夹紧方法,直角对刀块与塞尺组合的对刀方法。为保证设计的可靠性,还对夹具的夹紧力和精度进行了分析。同时使设计基准与定位基准相重合,保证了槽侧面的加工精度与位置公差。随后,本文又对铣床夹具各组件的结构尺寸进行了明确的设计,并用UG三维软件对整个夹具进行建模和装配。该铣床夹具在设计之初就注重结构工艺性,所以这套夹具结构简易、紧凑,操作起来也比较方便灵活。更重要的是,它在提高生产效率方面所起的作用尤为突出,体现了这次设计的主旨。

关键词:铣床;机床夹具;设计。

Milling Fixture Design

Abstract:When machine-finishing components, if jig can be widely used, it can save when the processing enormously the non-cutting time, reduce worker's labor, enhance the product the quality and the labor productivity. This article mainly introduced the design milling jig general step and method. Designs the tongs to carry on the analysis first generally to the firsthand information, is clear about the design the request and the intention, then proposes the concrete localization, the clamp, to the knife plan and the fixture body's general structure. This article uses six tlocalizations he localization methods, the clamp method which the binding screw and the bidirectional clamp combine, the right angle combines to the knife block and the feeler gauge to the knife method. For guarantee design reliability, but also has carried on the analysis to fixture's clamping force and the precision. Simultaneously caused the design datum and the localization datum superposes, has guaranteed the trough side working accuracy and the location tolerance. Afterward, this article has carried on the explicit design to the milling fixture various modules' structure size, and carries on the modeling and the assembly with the UG three dimensional software to the entire fixture. This milling jig pays great attention the structure technology capability at the beginning of the design, therefore this box splints sign a legal statement the construction simple, compact, operates is also quite convenient nimbly. More importantly, it the role outstandingly which plays in the enhancement production efficiency aspect, has manifested this design primary intention.

Key word: Milling machine; milling jig; design.

目录

一、绪论.................................................................................................................................1

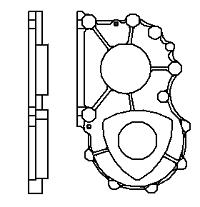

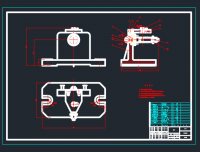

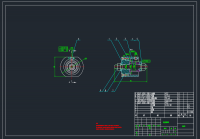

二、零件的分析及生产类型的确定..............................................................................3

1、零件的作用.............................................................................................................3

2、零件的工艺分析....................................................................................................3

3、零件的生产类型....................................................................................................4

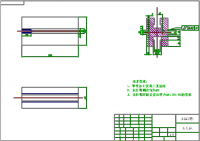

三、零件毛坯的设计..........................................................................................................5

1、选择毛坯..................................................................................................................5

2、毛坯尺寸公差与机械加工余量的确定...........................................................5

3、确定毛坯尺寸.........................................................................................................6

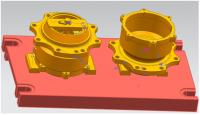

4、设计毛坯图.............................................................................................................7

四、零件的加工工艺设计.................................................................................................8

1、定位基准的选择....................................................................................................8

2、零件表面加工方法的选择..................................................................................9

3、拟订工艺路线.........................................................................................................9

4、工艺方案的比较与分析.....................................................................................11

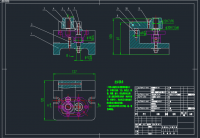

五、工序设计......................................................................................................................13

1、选择加工设备与工艺装备................................................................................13

2、确定工序尺寸.......................................................................................................13

3确定铣削用量及基本时间....................................................................................13

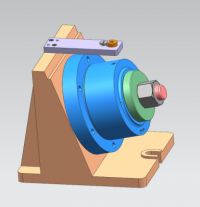

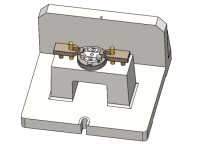

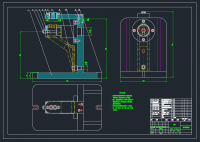

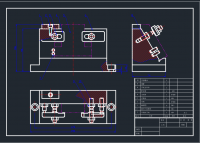

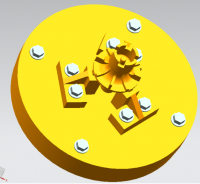

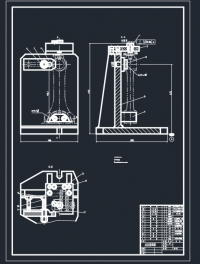

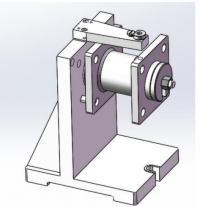

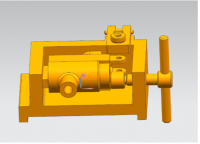

六、夹具的设计..................................................................................................................27

1、工件的定位............................................................................................................27

2、夹紧装置.................................................................................................................28

3、对刀装置.................................................................................................................28

4、夹具与机床机床的对定.....................................................................................29

5、误差分析与计算...................................................................................................30

七、总结................................................................................................................................32

参考文献...............................................................................................................................33

参考文献

[1]吴慧媛,韩邦华,零件制造工艺与装备[M],北京:电子工业出版社,2010.2.

[2]许晓旸,专用机床设备设计[M],重庆:重庆大学出版社,2003.

[3]高晓康,陈于萍,互换性与测量技术[M],北京:高等教育出版社,2009.1.

[4]顾京,现代机床设备[M],北京:化学工业出版社,2009.3.

[5]姚民雄,华红芳,机械制图[M],北京:电子工业出版社,2009.1.

[6]吴拓,现代机床夹具设计[M],北京:化学工业出版社,2011.7.

[7]薛源顺,机床夹具设计[M],北京:机械工业出版社,2011.8.

[8]吴建生,工程力学[M],北京:机械工业出版社,2011.7

[9]孙燕华,先进制造技术[M],北京:电子工业出版社,2009.6.

[10]周永强,高等学校毕业设计指导[M],北京:中国建材工业出版社,2002。

[11]乐兑谦,金属切削刀具,机械工业出版社,2005:4-17。

[12]许鸿本,机床夹具设计手册[M],沈阳:辽宁科学技术出版社,2004.3

[13]王建石,机床夹具和辅具[M],北京:机械工业出版社,2007.4

http://www.bysj1.com/cat.asp?id=23

http://www.bysj1.com/cat.asp?id=25