基于UG的CA6140拨叉(二)机械加工工艺与铣夹具设计

摘 要

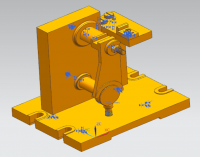

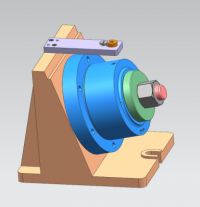

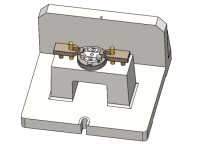

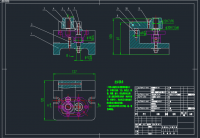

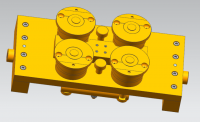

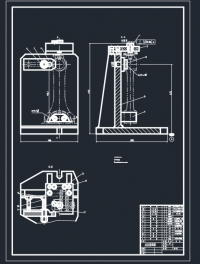

随着科技的发展,机械制造业在各行各业都普遍存在,无论是普通产业还是精密工业,都离不开机械制造设备,机械制造业成了众多企业的基础,科技的进步和社会的发展都离不开机械制造设备。本次的毕业设计的主要内容是CA6140拨叉(二)机械加工工艺规程制定以及铣床夹具的设计。其中,机械加工工艺规程编制方面,主要是通过对拨叉零件图以及各种机械加工技术要求进行分析,再根据相关的文献,查询资料,根据实际情况编制零件的机械加工工艺路线;根据工艺路线的内容确定各道工序的加工方法、机床、刀具等加工设备的选择,从而计算各工序的切屑用量,其中还包括基准的选择、定位夹紧方案的选定,之后完成工序卡、工艺卡和工艺过程卡的填写。另外,设计铣槽的专用夹具以及夹具装配三维图的装配等。

关键词:拨叉;工艺规程;专业夹具

目 录

第一章 零件的认识与分析

一、零件的分析····················································11

1.零件的作用······················································11

2.零件的结构······················································11

3.零件的工艺分析··················································11

(1).工艺分析的目的··············································11

(2).拨叉的工艺分析··············································11

(3).拨叉的加工内容··············································12

第二章 设计零件的加工方法································13

一、确定毛坯的制造形成············································13

二、机械加工工艺规程设计··········································13

1.生产过程及机械加工工艺规程······································13

(1).工艺规程的定义··············································13

(2).工艺规程的主要作用··········································13

2.机械加工工艺规程的种类··········································13

3.制定机械加工工艺规程的原始材料··································13

三、选择加工方法拟定工序路线······································14

1.定位基准的选择··················································14

(1)粗基准选择···················································14

(2)精基准选择···················································15

2.合理的机械加工工艺路线的重要性··································15

3.拟定工艺路线····················································15

(1)工艺路线方案一···············································15

(2)工艺路线方案二···············································16

(3)工艺路线的比较与分析·········································16

(4)最终工艺方案··················································17

四、机械加工余量、工序尺寸及毛坯尺寸的确定························18

1.毛坯余量及尺寸的确定············································18

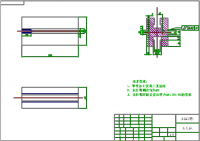

(1)粗铣Φ55拨叉脚的上下端面的加工余量和公差····················18

(2)粗铣16㎜槽上表面的加工余量和公差····························18

(3)铣35斜面的加工余量和公差····································18

2.各加工表面的机械加工余量,尺寸工序及毛坯尺寸的确定··············18

五、确定切削用量及基本工时········································20

1.切削用量·······················································20

(1)切削用量的定义···············································20

(2)切削用量选择的原则···········································20

2.切削用量的计算··················································21

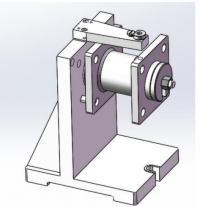

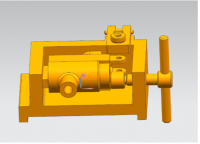

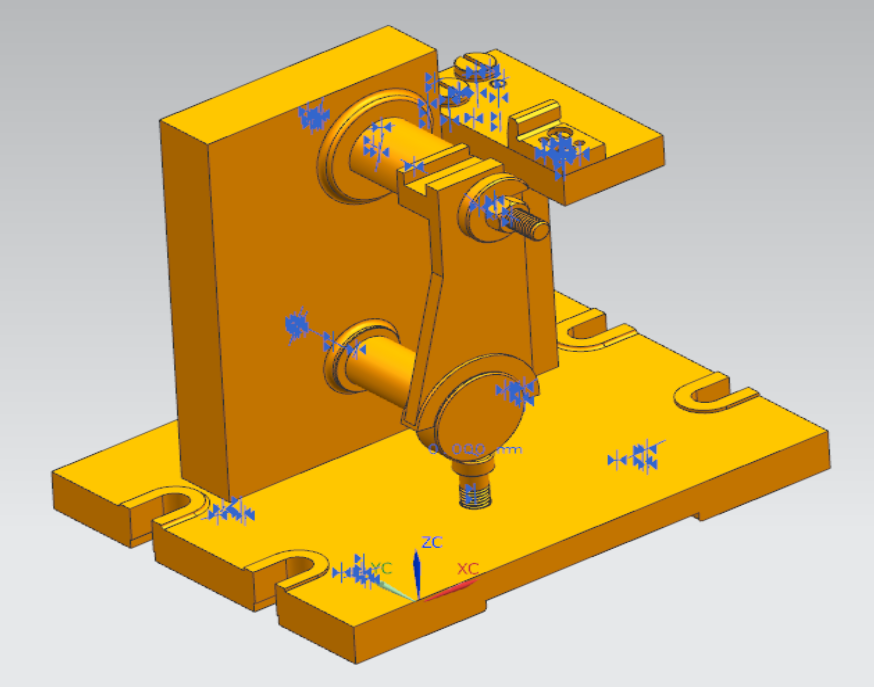

第三章 机床夹具设计··········································29

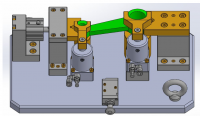

一、设计夹具的基本要求············································29

二、确定夹具类型···················································29

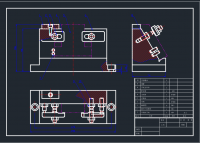

三、确定定位方案··················································29

1.基准的选择·······················································29

2.自由度的限制····················································31

四、确定夹紧方案··················································31

五、对刀装置的选择················································31

六、夹具体与主要零件··············································34

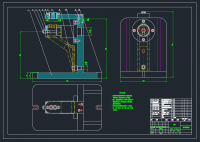

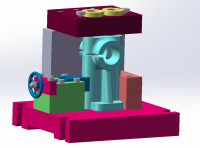

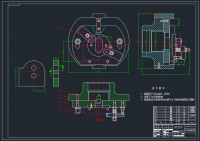

七、绘制夹具装配总图和主要零件图··································34

总结并致谢························································38

参考文献··························································40

第一章 零件的认识与分析

一、零件的分析

1、零件的作用

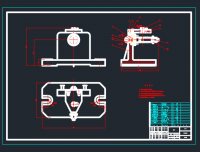

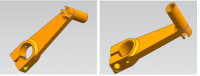

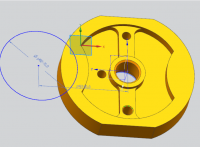

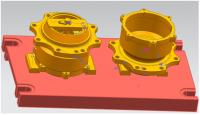

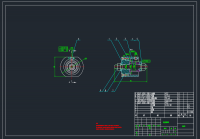

所给的零件是车床CA6140的拨叉,它是车床变速机构中的一个部件,主要起换挡作用,让主轴的回转运动按照使用者的要求获得相应的速度和扭矩。零件中的Φ25孔与车床上的操纵机构相连接,Φ55的半圆孔是与控制齿轮所在的轴接触的,通过上方的力拨动下方的齿轮变速。该零件铸造时是两个一体的,加工的时候是分开的。

2、零件的结构

零件的一端是Φ55的半圆孔和Φ75的左右端面,另一端是Φ25的通孔,在Φ40的外圆柱面上有一个外圆斜面,在顶端有个16×8的槽。

3、零件的工艺分析

(1)工艺分析的目的

工艺分析的目的,一是为了审查零件的结构形状及尺寸精度、相互位置精度、表面粗糙度、材料及热处理等的技术要求是否合理,是否便于加工装配;二是通过工艺分析,对零件的工艺要求有进一步的了解,以便制定出合理的工艺规程。

参考文献

[1] 王光斗,王春福。机床夹具设计手册[M] 上海:上海科学技术出版社,2000.11

[2] 赵如福。金属机械加工工艺人员手册[M] 上海:上海科学技术出版社,1992.12

[3] 杨叔子。机械加工工艺师手册[M] 北京:机械工业出版社,2004.9

[4] 吴慧媛,韩邦华。零件制造工艺与装备——机械制造技术 北京:电子工业出版社,2011,8

[5] 上海市金属切削技术协会。金属切削手册[M] 上海:上海科学技术出版社,1998

[6] 胡家秀.简明机械零件设计实用手册[M] 北京:机械工业出版社,2012