支架工艺及铣Φ14mm和Φ22mm孔端面夹具设计

一、选题简介、意义

. 随着社会发展的需要,机械加工作为一个传统而富有活力的行业,在现经济时代,其行业发生着结构性变化,工艺工装的设计与改良已成为企业生存和发展的必要条件,工艺工装的设计与改良直接影响加工产品的质量与性能。

本次设计是在学完了大学的全部基础课,专业课之后进行的;是我们在进行毕业实习之前对所学各课程的一次深入的综合性设计,要求我们运用先前所学的知识进行工艺与夹具的设计,通过这次毕业设计对自己未来将从事的工作进行了一次适应性训练,从中锻炼自己查阅相关资料、分析问题、解决问题的能力,能够更深入理解课本知识,对设计中涉及到的机械制造工艺规程,工艺方案论证,机械加工余量计算,工艺尺寸的确定,编写技术文件及专用夹具的设计与计算等各个方面有了更好的掌握,并能够更好的应用理论知识,为以后更好地胜任工作岗位打好基础,同时也是一次理论与实际相结合的训练。

二、研究的主要内容,拟解决的主要问题

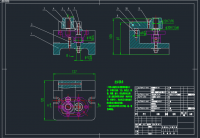

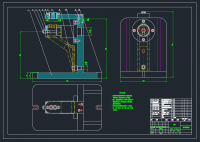

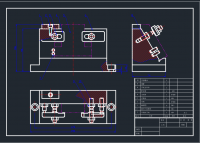

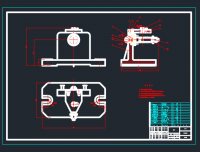

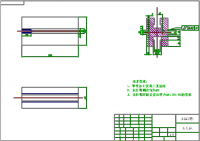

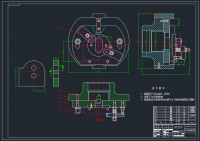

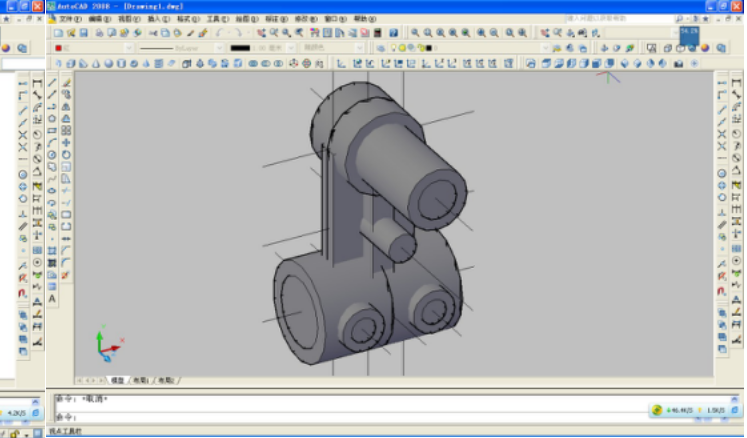

根据毕业设计任务要求,主要研究了支架工艺及铣Φ14mm和Φ22mm孔夹具设计机械加工工艺过程的编制。首先介绍了支架工艺及铣Φ14mm和Φ22mm孔夹具设计作用和工艺分析,其次确定了毛坯尺寸,绘制了生产工件的毛坯图和零件图,然后进行了工艺规程设计,并附有生产工艺过程卡,机械加工工艺卡以及机械加工工艺卡,最后进行对铣下平面夹具设计,指出了工件的定位、夹紧、导向及其他元件或装置的结构形式,并对加工工序进行了精度校核。

通过这次设计,能够综合运用机械专业相关理论知识,分析和解决机械加工工艺问题,初步具备设计中等复杂程度零件的工艺规程的能力;能根据被加工零件的技术要求,运用夹具设计的基本原理和方法,学会拟定夹具设计方案,完善夹具结构设计,初步具备设计保证加工质量的高效、省力、经济合理的专用夹具的能力。

三、研究(工作)步骤、方法及措施(思路)

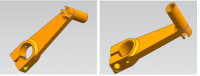

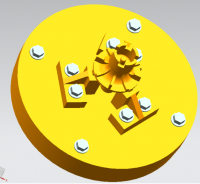

此次设计是对支架工艺及铣Φ14mm和Φ22mm孔夹具设计机械加工工艺过程的编制及铣下平面夹具设计,其零件为铸件,具有体积大,零件结构复杂的特点,由于面比孔易加工,在制定工艺规程时,就先加工面,再以面为基准来加工其它,其中各工序夹具都采用专用夹具,其机构设计简单,方便且能满足要求。其内容及具体要求如下:

(1)分析研究被加工零件,画出零件图。

(2)确定生产类型和工艺特征。

(3)选择毛坯种类及制造方法,确定毛坯尺寸,绘制毛坯图。

(4)选择加工方法,拟定工艺路线。

(5)进行工序设计和工艺计算。

(6)画出工序简图,填写工艺文件。

(7)设计专用夹具。

(8)编写毕业设计说明书。

目 录

第一章 绪论······································································································1

1.1 本课题的研究内容和意义选题的意义····························································1

1.2 国内外的发展概况···················································································1

1.3本课题应达到的要求················································································2

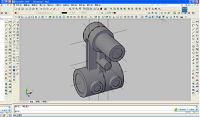

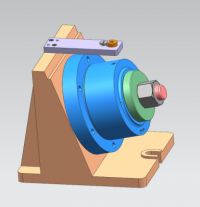

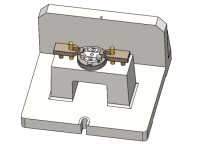

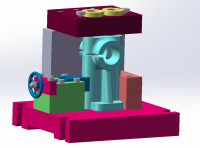

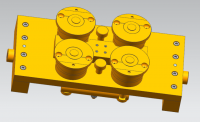

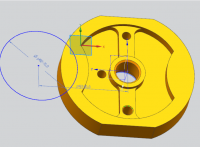

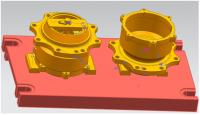

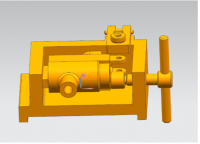

第二章 支架零件的三维造型······································································4

第三章 零件分析······························································································11

3.1 零件的作用·····························································································11

3.2 零件的工艺分析················································································11

第四章 工艺规程设计························································································13

4.1 确定毛坯的制造形成·················································································13

4.2 工艺过程设计所应采取的相应措施·····························································13

4.3 定位基准面的选择··················································································13

4.3.1 粗基准的选择························································································13

4.3.2 精基准的选择························································································14

4.4 制定工艺路线···························································································14

4.5 机械加工余量、工序尺寸及毛坯尺寸的确定···············································16

4.6 确定切削用量及基本工时··········································································16

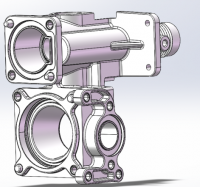

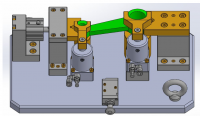

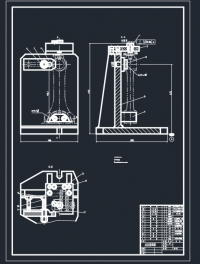

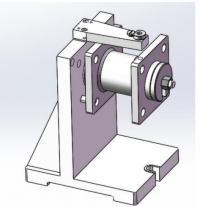

第五章 专用普通夹具设计·················································································31

5.1设计主旨·································································································31

5.2夹具设计·································································································31

5.2.1定位基准的选择···················································································31

5.2.2切削力及夹紧力计算············································································31

5.2.3定位键、对刀块、塞尺的设计······························································33

5.2.4活动V形块的设计···············································································35

5.2.5夹具体的设计······················································································35

5.2.6夹具精度分析······················································································35

5.2.7夹具设计及操作的简要说明·································································37

毕业设计小结··································································································38

参考文献··························································································41

致谢···································································································42

附录·············································································································43

参考文献

[1]《零件制造工艺与装备》 吴慧媛编. 电子工业出版社 2010

[2]《切削用量手册》 艾兴 肖诗刚编 机械工业出版社 1985

[3]《机械制造工艺设计简明手册》 李益民编 机械工业出版社 1994

[4]《机械原理》 黄锡恺,郑文伟编 人民教育出版社,1981

[5]《气压传动及控制》 郑洪生编 机械工业出版社,1987

[6]《Solidworks快速入门教程》 詹迪维编 机械工业出版社 2010

[7] 《Solidworks高级教程简编》 陈超祥编 机械工业出版社2010

[8]《机械设计课程设计》 熊娟,阳尧端编 复旦大学出版社 2010

[9]《现代夹具设计手册》 朱耀祥,浦林祥编 机械工业出版社 2010

[10]《机床夹具和辅具速查手册》 王建石编 机械工业出版社2007

[11]《气压传动与控制》 吴振顺编 哈尔滨:哈尔滨工业大学出版社,1995

[12]《气压传动》 徐永生编 机械工业出版社,1990

[13]《机械设计》 吴宗泽 主编 第一版. 中央广播电视大学出版社,1998

[14]《非标准零件手册》 第三版 国防工业出版社1997

[15]《液压与气压传动》 左建民 主编 第二版.北京:机械工业出版社,1999

[16]《液压控制系统》 (美)H﹒E﹒梅里特著.陈燕庆译 科学出版社.1979

[17]《液压技术基本理论》 (日)市川常雄著.鸡西煤矿机器厂译 煤炭工业出版社.1975

[18]《AutoCAD2000机械制图》 孙燕华 主编 北京:机械工业出版社,2002,9

[19]《机械制图》 金大鹰 主编 北京:机械工业出版社,2001,7

[20]《飞机液压传动与伺服控制》(上册) 李培滋﹑王占林主编 国防工业出版社.1989

[21]《泵的排量设计工况及优化设计》 文怀兴主编 北京.机械工业出版社.2005

[22]《液压气动技术手册》 路甬祥主编 北京.机械工业出版社.2002

[23]《液压传动》 张赤诚等编 地质出版社.1986

[24]《液压传动和液力传动》 齐任贤主编 冶金工业出版社.1981

附录

1.机械加工工艺过程卡1张

2.机械加工工艺卡1张

3.机械加工工艺工序卡2张

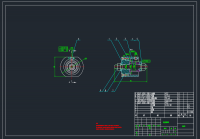

4.CAD图6张