电机连接轴的设计及机加工工艺

摘要:随着数控技术的不断发展和应用领域的扩大,数控加工技术对国计民生的一些重要行业(IT、汽车、轻工、医疗等)的发展起着越来越重要的作用,因为效率、质量是先进制造技术的主体。高速、高精加工技术可极大地提高效率,提高产品的质量和档次,缩短生产周期和提高市场竞争能力。而对于数控加工,无论是手工编程还是自动编程,在编程前都要对所加工的零件进行工艺分析,拟定加工方案,选择合适的刀具,确定切削用量,对一些工艺问题(如对刀点、加工路线等)也需做一些处理。并在加工过程掌握控制精度的方法,才能加工出合格的产品。

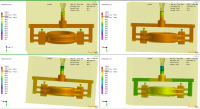

本文根据数控机床的特点,针对具体的零件,进行了工艺方案的分析,工装方案的确定,刀具和切削用量的选择,确定加工顺序和加工路线,数控加工程序编制。通过整个工艺的过程的制定,充分体现了数控设备在保证加工精度,加工效率,简化工序等方面的优势。

关键词: 工艺分析:加工方案:进给路线:控制尺寸

The connecting shaft of motor design and machining process

Abstract: With the continuous development of numerical control technology and application in the field of expanding, nc machining technology to the national economy and people's livelihood some important industry (IT, automobile, light industry, medical, etc.) is playing a more and more important role in the development, because the efficiency, quality is the main part of the advanced manufacturing technology. High speed, high precision machining technology can greatly increase efficiency, improve the quality and grade of products, shorten production cycle and improve the market competition ability. For the numerical control processing, whether manual programming or automatic programming, before will be made on the processing of parts process analysis, drafting processing program, select the appropriate cutting tools, cutting parameter is determined, to some process problems (such as the cutting point, processing route, etc.) also need to do some processing. And master control precision in machining process method, to work out qualified products.

In this paper, according to the characteristics of the nc machine tool, in view of the specific parts, the process of analysis, the scheme determination of tooling, cutting tool and cutting parameter selection, determine the processing order and processing route, the nc machining programming. Through the whole process of developing process, fully embodies the nc equipment in the guarantee machining accuracy, efficiency, simplify the procedure of advantage.

Keywords: Technology analysis, Processing scheme, Feed line Control the size

目录

摘要······································································1

目录······································································2

第一章绪论

1.1选题的意义························································4

1.2研究的主要内容·····················································4

1.3课题研究完成后的成果···············································4

1.4本章小节···························································4

第二章 数控概述

2.1数控机床简介·······················································5

2.2数控机床特点·······················································5

2.3数控机床的组成·····················································5

2.4数控机床发展趋势···················································6

2.5本章小节···························································7

第三章 电机连接轴工艺设计

3.1定生产类型·························································8

3.2零件结构的分析·····················································9

3.3毛坯的选择························································11

3.4 确定合理的装夹方式················································11

3.5定位及基准的选择··················································11

3.6刀具的选择························································11

3.7工艺路线··························································12

3.8本章小节··························································13

第四章 电机连接轴参数计算

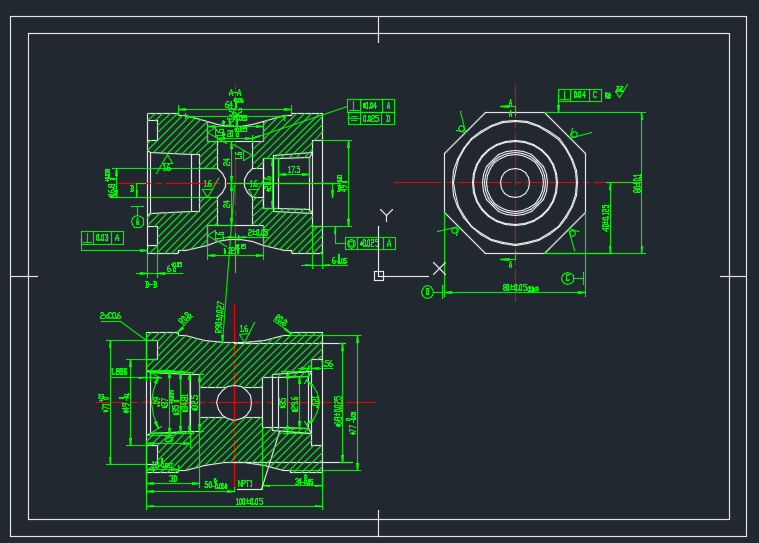

4.1钻Φ16通孔························································14

4.2精车Φ16.8内孔···················································15

4.3扩钻Φ25孔·······················································15

4.4粗车Φ49内孔螺纹锥孔及Φ28.6内孔································16

4.5精车Φ49内孔螺纹锥孔及Φ28.6内孔·······························17

4.6粗车左端Φ32.5内孔及锥孔········································18

4.7精车左端Φ32.5内孔及锥孔·········································19

4.8粗镗Φ20孔深80mm················································20

4.9铰Φ20H7孔·······················································21

4.10车削左端面凹槽··················································21

4.11粗车Φ32台阶孔··················································22

4.12精车Φ32台阶孔··················································23

4.13粗车R90圆弧及Φ88外圆R0.8圆角·································25

4.14精车R90圆弧及Φ88外圆R0.8圆角··································26

4.15本章小节························································26

第五章 回顾总结

5.1课题成果··························································27

5.2存在问题··························································27

5.3收获体会. ·························································27

致谢·····································································28

参考文献·································································19

附录·····································································30

第一章绪论

1.1选题的意义

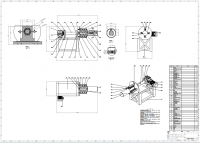

本次毕业设计选定的题目是电机连接轴的设计及机加工工艺,能够让我们充分利用在学校所学的知识分析零件图纸及机械加工工艺过程,利用UG ,CAXA电子图版绘制电机连接轴的三维实体模型及二维图纸,分析零件的重要尺寸及粗糙度的要求,合理选择夹具装夹工件,优化工艺路线,数控加工刀具的选择及切削用量的计算,减少加工时间等等,毕业设计是对我们在大学三年所学知识的一次综合利用,考察。对我们以后走上工作岗位是十分有利的。

1.2课题研究的主要内容

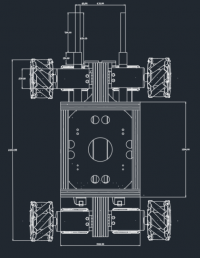

本次毕业设计电机连接轴的设计及机加工工艺,侧重于该零件的工艺分析、加工路线的确定及夹具毛坯的选择问题,并绘制零件图。其中零件工艺规程的分析是此次论文的重点和难点轴。

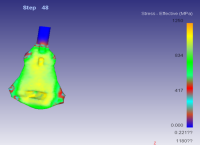

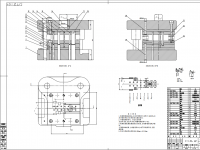

从零件的图纸设计到零件成品合格交付,要考虑到零件加工工艺线路的安排、加工机床的选择、切削刀具的选择、零件加工中的定位装夹等一系列因素的影响。必须要对零件设计图纸和技术要求进行详细的数控加工工艺分析,分析零件图此零件粗糙要求较高需精加工,选择四爪卡盘装夹,在加工过程中需调头加工这就需要考虑基准选择及加工完成后尺寸的保证问题等等。

1.3课题研究完成后的成果

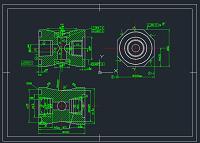

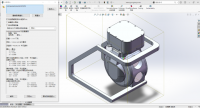

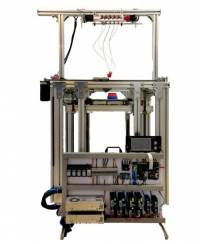

1.完成电机连接轴的二维图绘制,三维绘制;

2.完成惰轮轴机械加工工艺路线的制定,相关工艺过程卡及工序卡一份;

3编写电机连接轴说明书一份;

1.4本章小节

通过本章学习深刻了解到毕业设计课题研究的意义所在,知道了课题研究的主要内容,在做毕业设计时所要完成的任务,一些重点知识方面需要注意的问题,课题完成后的成果的。

第二章 数控概述

2.1数控机床简介

数控机床是数字控制机床(Computer numerical control machine tools)的简称,是一种装有程序控制系统的自动化机床。该控制系统能够逻辑地处理具有控制编码或其他符号指令规定的程序,并将其译码,从而使机床动作并加工零件。

数控机床种类繁多,由数控系统通过伺服驱动系统去控制各运动部件的动作,主要用于轴类和盘类回转体零件的多工序加工,具有高精度、高效率、高柔性化等综合特点,适合中小批量形状复杂零件的多品种、多规格生产。

2.2数控机床特点

数控机床的操作和监控全部在这个数控单元中完成,它是数控机床的大脑。与普通机床相比,数控机床有如下特点:

1、加工精度高,具有稳定的加工质量;

2、可进行多坐标的联动,能加工形状复杂的零件;

3、加工零件改变时,一般只需要更改数控程序,可节省生产准备时间;

4、机床本身的精度高、刚性大,可选择有利的加工用量,生产率高(一般为普通机床的3~5倍);

5、机床自动化程度高,可以减轻劳动强度;

6、对操作人员的素质要求较高,对维修人员的技术要求更高。

2.3数控机床的组成

数控机床一般由下列几个部分组成:

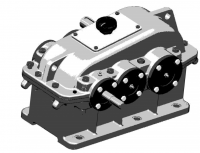

1、主机,他是数控机床的主题,包括机床身、立柱、主轴、进给机构等机械部件,他是用于完成各种切削加工的机械部件。

2、数控装置,是数控机床的核心,包括硬件(印刷电路板、CRT显示器、键盒、纸带阅读机等)以及相应的软件,用于输入数字化的零件程序,并完成输入信息的存储、数据的变换、插补运算以及实现各种控制功能。

3、驱动装置,他是数控机床执行机构的驱动部件,包括主轴驱动单元、进给单元、主轴电机及进给电机等。他在数控装置的控制下通过电气或电液伺服系统实现主轴和进给驱动。当几个进给联动时,可以完成定位、直线、平面曲线和空间曲线的加工。

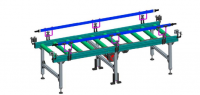

4、辅助装置,指数控机床的一些必要的配套部件,用以保证数控机床的运行,如冷却、排屑、润滑、照明、监测等。它包括液压和气动装置、排屑装置、交换工作台、数控转台和数控分度头,还包括刀具及监控检测装置等。

5、编程及其他附属设备,可用来在机外进行零件的程序编制、存储等。

2.4数控机床发展趋势

高速、精密、复合、智能和绿色是数控机床技术发展的总趋势,近几年来,在实用化和产业化等方面取得可喜成绩。主要表现在以下方面。

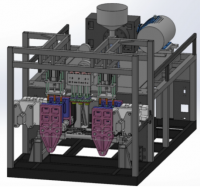

1、机床复合技术进一步扩展随着数控机床技术进步,复合加工技术日趋成熟,包括铣-车复合、车铣复合、车-镗-钻-齿轮加工等复合,车磨复合,成形复合加工、特种复合加工等,复合加工的精度和效率大大提高。“一台机床就是一个加工厂”、“一次装卡,完全加工”等理念正在被更多人接受,复合加工机床发展正呈现多样化的态势。

2、智能化技术有新突破数控机床的智能化技术有新的突破,在数控系统的性能上得到了较多体现。如:自动调整干涉防碰撞功能、断电后工件自动退出安全区断电保护功能、加工零件检测和自动补偿学习功能、高精度加工零件智能化参数选用功能、加工过程自动消除机床震动等功能进入了实用化阶段,智能化提升了机床的功能和品质。

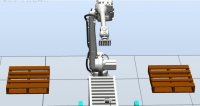

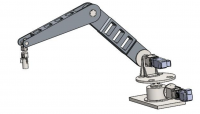

3、机器人使柔性化组合效率更高机器人与主机的柔性化组合得到广泛应用,使得柔性线更加灵活、功能进一步扩展、柔性线进一步缩短、效率更高。机器人与加工中心、车铣复合机床、磨床、齿轮加工机床、工具磨床、电加工机床、锯床、冲压机床、激光加工机床、水切割机床等组成多种形式的柔性单元和柔性生产线已经开始应用。

4、精密加工技术有了新进展数控金切机床的加工精度已从原来的丝级(0.01mm)提升到目前的微米级(0.001mm),有些品种已达到0.05μm左右。超精密数控机床的微细切削和磨削加工,精度可稳定达到0.05μm左右,形状精度可达0.01μm左右。采用光、电、化学等能源的特种加工精度可达到纳米级(0.001μm)。通过机床结构设计优化、机床零部件的超精加工和精密装配、采用高精度的全闭环控制及温度、振动等动态误差补偿技术,提高机床加工的几何精度,降低形位误差、表面粗糙度等,从而进入亚微米、纳米级超精加工时代。

5、功能部件性能不断提高功能部件不断向高速度、高精度、大功率和智能化方向发展,并取得成熟的应用。全数字交流伺服电机和驱动装置,高技术含量的电主轴,高精度主轴单元等功能部件推广应用,极大的提高数控机床的技术水平。

2.5本章小节

通过本章学习知道了数控的发展史,数控机床的组成,特点。对数控机床有更深的理解。通过本章也知道数控机床的发展趋势,将向高速、精密、复合、智能和绿色方向发展。

参考文献

[1]《机械制造工艺与装备》倪森寿 主编,-2版.- 北京:化学工业出版社,2009.1

[2]《切削用量简明手册》艾兴 肖诗纲 主编,-版.-北京:机械工业出版社,2002.6

[3]《典型零件机械加工生产实例》陈宏钧 主编,-2版.-北京:机械工业出版社,2010.9

[4]其中数控概述选自数控技术百度文库http://baike.baidu.bysj1.com/subview/87747/5095018.htm?fr=aladdin

附录

1.电机连接轴说明书

2.机械加工工艺过程卡

3.机械加工工艺工序卡

4.机械加工工艺卡

5.电机连接轴CAD

6.电机连接轴UG

7.开题报告

8.任务书

9.毕业设计(论文)指导记录表

10.用人单位毕业设计鉴定表