目 录

第一章 前言

1.1本课题的基本内容,预计解决的难题 1

1.1.1本课题的基本内容 1

1.1.2预计解决的难题 1

1.2 课题的研究方法、技术路线 1

1.2.1研究方法 1

1.2.2技术路线 2

1.3 研究工作条件和基础 2

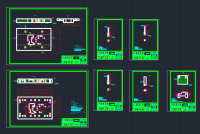

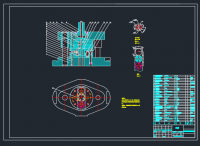

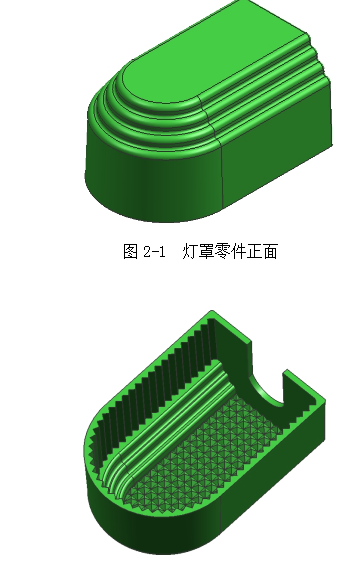

第二章 塑件的分析

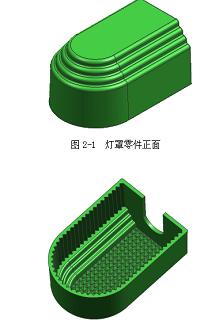

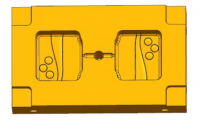

2.1外形的尺寸 3

2.2精度等级 4

2.3塑件的结构设计 4

2.3.1脱模斜度.................................................................................................................4

2.3.2塑件的壁厚.............................................................................................................4

2.3.3塑件的圆角.............................................................................................................5

2.3.4孔.............................................................................................................................5

2.4塑件尺寸及精度................................................................................................................5

2.5塑件表面粗糙度................................................................................................................6

2.6塑件的体积和质量............................................................................................................6

第三章 注塑机选择

3.1初步选定注射机 7

3.1.1注射量的计算 7

3.2注射机的相关参数选择校核 8

3.3设备的型号及选择 9

3.3.1注射成型工艺 9

3.3.2注射机的选用 9

3.3.3按照预选型腔数来选择注射机 9

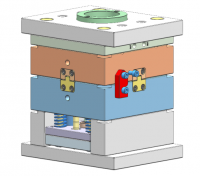

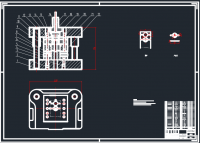

第四章 成型零件的设计

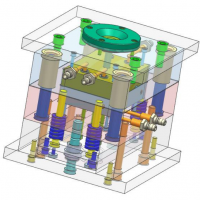

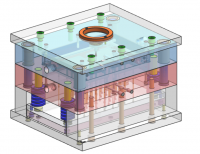

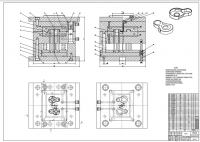

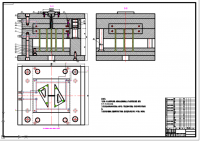

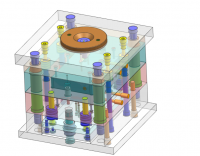

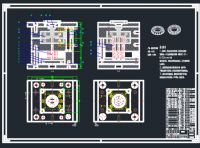

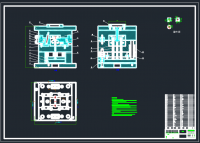

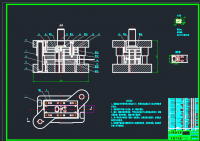

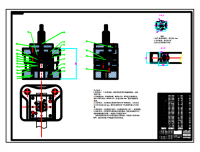

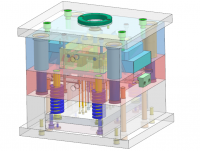

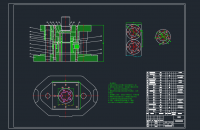

4.1成型零件的结构设计 13

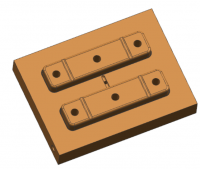

4.1.1 凹模的结构 13

4.1.2 凸模结构 13

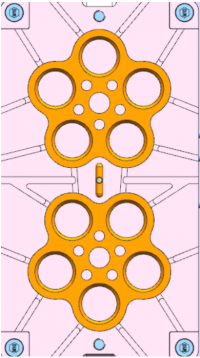

4.2浇注系统的设计 15

4.2.1 确定浇注系统的设计原则 15

4.2.2 主流道的设计要点 16

4.2.3 主流道的设计 17

4.2.4 浇口位置的选择 18

4.2.5 排气系统的设计 18

4.3成型零部件的结构设计与计算 19

4.3.1 成型零件的结构设计 19

4.3.2 成型零件的工作尺寸计算 19

4.3.3 型芯的尺寸计算 19

4.3.4 合模导向定位结构 21

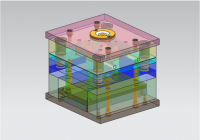

4.4模架的确定 21

第五章 结论 23

小 结 24

参考文献 25

英文翻译

Our plastic industry from the start to now, after half a century, has made significant progress, the mold has been greatly improved. In large molds capable of producing 48 inches large screen TV Molded injection mold, 6.5kg capacity washing machine full set of plastic molds and car bumpers and instrument panels and other plastic mold overall; precision plastic molds, the camera is capable of producing plastic molds, multi-cavity molds and small module gear plastic mold. Such as Tianjin and Yantai glory days and Electrical Co., Ltd. Polaris IK mold manufacturing multi-cavity mold gear VCD and DVD, the dimensional accuracy of such gear in the production of plastic parts, coaxial, beating other requirements have reached similar foreign the level of the product, but also using the latest gear design software, correcting errors due to tooth mold shrinkage caused reached the standard involute requirements. Can produce a thickness of only 0.08mm high mold cavity two aviation cup mold and extrusion die difficulty plastic windows and so on. Manufacturing precision injection mold cavity up to 0.02 ~ 0.05mm, the surface roughness Ra0.2μm, mold quality, life significantly improved, non-hardening steel life of up to 10 to 30 million times, hardened steel up to 50 to 10 million times, shorter delivery time than before,And abroad is still a large gap compared.

In terms of manufacturing technology, a new level CAD / CAM / CAE technology, based on the application level, and in the production of household appliances enterprises as representatives have introduced a significant number of CAD / CAM systems, such as the United States of EDS UGⅡ, US ParametricTechnology company

Pro / Emgineer, USA CV's CADS5, British Deltacam company DOCT5, Japan HZS company CRADE, Israeli companies Cimatron, US AC-Tech's C-Mold and Australia Moldflow's

MPA mold analysis software, and so on. The introduction of these systems and

software, although it takes a lot of money, but in China's mold industry, to achieve an integrated CAD / CAM and CAE technologies to support the process of forming,

filling and cooling as computer simulation, has made some technical and economic benefits, promote and facilitate the development of mold CAD / CAM technology.

In recent years, China has independently developed plastic CAD / CAM system has

made significant progress, mainly in Northern China being developed by the Software Engineering Institute CAXA system, Huazhong University of Science developed injection mold HSC5.0 systems and CAE software, these The software has to adapt to the specific circumstances of domestic mold can be used in the computer and lower prices, etc., in order to further universal mold CAD / CAM technology has created favorable conditions.

With precision and mold to develop in the direction of large, precision than super finishing techniques and collector, chemical, ultrasonic, laser and other technologies integrated together 1μm composite processing mold manufacturing in the future will have broad prospects. High-speed machining the workpiece surface was smooth, save processing time, typically only a step away from 0.0254mm, and sharp point only 0.001mm high, after most of the high-speed machining the workpiece surface is very smooth, without further processing fitter now, machine tool manufacturers are keen to produce specially designed for high-speed machining processing center, high-speed processing technology in the United States to reduce or omit fitter process is a considerable efficiency measures, this technique is also popular in Europe and Japan Welcome. In addition, with a fully hardened material processing mold cavity mold processing industry is another important trend of mild high spindle speed and a small cutting tool radius were formed enough torque that can be used to process metallic material hardness up to 64HRC, since no further grinding heat treatment, after heat treatment and tempering conventional offset by geometric distortion caused by the heat treatment carried out is also not needed, and the technique in Japanese acclaimed, now in The United States also received extensive attention and positive spread in Europe.

Molding process, the multi-material plastic molding, high efficiency multi-color injection molding, insert swap structure and core ejection mechanism

of innovative design has also made great progress. Gas-assisted injection molding technology using more mature, such as Qingdao Hisense Mould Co., Ltd., Tianjin

communications and broadcasting companies and other manufacturers to successfully

mold factory on TV 29 to 34 inches thick shell and some parts of the mold using

gas-assisted technology, some manufacturers also used the C-MOLD gas-assisted

software, to achieve better results. Companies such as Shanghai New Pres able to provide users with gas-assisted molding equipment and technology. Hot runner mold began to promote, some plants using rate of more than 20%, the general formula or external heat hot hot runner system, a few units using tough needle-type runner device has the world's advanced level, a few units using the world advanced level of difficulty needle hot runner mold. But overall runner adoption rate of less than 10%, compared with 50 to 80% abroad, the gap is large.

With the rapid development of new technologies, foreign countries have emerged mold automatic processing system, the system consists of multiple machines rational combination with accompanying positioning fixture or positioning disk, a complete equipment, tool NC and CNC flexible database synchronization system with real-time quality monitoring and control system.

参考文献

[1] 齐卫东. 塑料模具设计与制造【M】. 北京:高等教育出版社,2008.

[2] 阎压林. 塑料模具图册【M】. 北京:高等教育出版社,2006.

[3] 塑料模具技术手册编写组. 塑料模设计手册【M】. 北京:机械工业出版社,2001.

[4] 唐志玉. 塑料设计师指南【M】.北京:国防工业大学出版社,2009

[5] 颜智伟. 注射模具设计与机构设计【M】. 修订版. 台北:“全华科技图书股份有限公司”,2009.

[6] 李学锋. 塑料模具设计与制造【M】.北京:机械工业出版社,2010.

[7] 王树勋.邓庚厚. 典型注塑模具结构图册【M】.长沙:中南工业大学出版社,2002.

[8] 塑料模具设计手册编写组. 塑料模设计手册【M】.北京:机械工业大学出版社,2003.

[9] 高为国. 模具材料【M】.北京:机械工业大学出版社,2005.

[10]陈治刚. 塑料成型工艺与模具设计【M】. 北京:机械工业出版社,2007.

[11]付宏生. 塑料成型模具设计【M】. 北京:化学工业出版社,2009.

http://www.bysj1.com/ http://www.bysj1.com/html/4068.html

http://www.bysj1.com/html/3268.html