滑轮手柄数控加工工艺设计与编程

摘 要

在车床上,利用工件的旋转运动和刀具的直线运动或曲线运动来改变毛坯的形状和尺寸,把它加工成符合图纸的要求。

车削加工是在车床上利用工件相对于刀具旋转对工件进行切削加工的方法。车削加工的切削能主要由工件而不是刀具提供。车削是最基本、最常见的切削加工方法,在生产中占有十分重要的地位。车削适于加工回转表面,大部分具有回转表面的工件都可以用车削方法加工,如内外圆柱面、内外圆锥面、端面、螺纹和回转成形面等,所用刀具主要是车刀。

在各类金属切削机床中,车床是应用最广泛的一类,约占机床总数的50%。车床既可用车刀对工件进行车削加工,又可用钻头、铰刀、丝锥和滚花刀进行钻孔、铰孔、攻螺纹和滚花等操作。按工艺特点、布局形式和结构特性等的不同,车床可以分为卧式车床、落地车床、立式车床、转塔车床以及仿形车床等,其中大部分为卧式车床。

数控车削加工是现代制造技术的典型代表,在制造业的各个领域如航天、汽车、模具、精密机械、家用电器等各个行业有着日益广泛的应用,已成为这些行业不可或缺的加工手段。

为了子数控机床上加工出合格的零件,首先需根据零件图纸的精度和计算要求等,分析确定零件的工艺过程、工艺参数等内容,用规定的数控编程代码和格式编制出合适的数控加工程序。编程必须注意具体的数控系统或机床,应该严格按机床编程手册中的规定进行程序编制。但从数控加工内容的本质上讲,各数控系统的各项指令都是应实际加工工艺要求而设定的。

关键词: 车削加工; 刀具; 零件的工艺过程; 程序编制。

ABSTRACT

On a lathe, using the workpiece rotation movement and the tool of the straight-line movement or curve motion to change the blank of shapes and sizes and put it into production accord with drawings requirements.

Turning processing is on a lathe tool relative to the workpiece rotate using of workpiece machining methods. Turning processing cutting can mainly by the workpiece instead of cutting tools provided. Turning is the most basic, the most common cutting processing methods in production, occupies very important position. Turning suitable for processing rotary surface, most has the rotary surface of workpiece can use turning processing, such as internal and external method YuanZhuMian, internal and external taper surface and face, threads and rotary shape face, USES the tool is mainly lathe tool.

In all kinds of metal cutting machine, lathe is the most widely used type of machine tools, accounting for approximately 50% of the total. Lathe tool can be used for workpiece machining and usable drill, reamer, taps and knurling knife drilling, reaming, tapping screw and knurling operation. According to the technological characteristics, layout form and structure characteristics of different, lathe can be divided into horizontal lathe, landing lathe, vertical lathe, turret lathe and imitation shape lathe, mostly for horizontal lathes.

The numerical control turning processing is the typical representative of modern manufacturing technology in manufacturing various fields, such as aerospace, automotive, dies, precision machinery, household appliances industries have more extensive application of has become an indispensable processing methods in these industries.

For the son nc machine processing qualified parts, must first according to drawings of the computation precision and requirements, etc, analyzed and determined by the components of the process, process parameters, etc., with provisions of nc programming codes and format formulate appropriate nc programs. Programming must pay attention to the specific of the nc system or machine tool, should strictly according to the machine programming handbook for programming. But from the nc machining content essentially, the numerical control system of various instructions are should actual processing process requirement set.

Because I CaiShuXueJian, lack of knowledge and experience, in the design process appears unavoidably not appropriate place, I hope each teacher to point out my mistakes and suggestion.

Keywords: turning machining tool parts craft process of programming

目 录

第一章 引言............................................................1

1.1 课题简介.................................. .................2

1.1.1课题研究的内容..............................................2

1.1.2课题研究的意义..............................................2

1.2 数控系统....................................................2

1.3数控加工的概念................................................3

1.3.1加工工艺...................................................4

1.4数控车床的特点...............................................5

第二章 零件机械加工工艺分析...........................................6

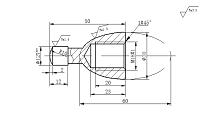

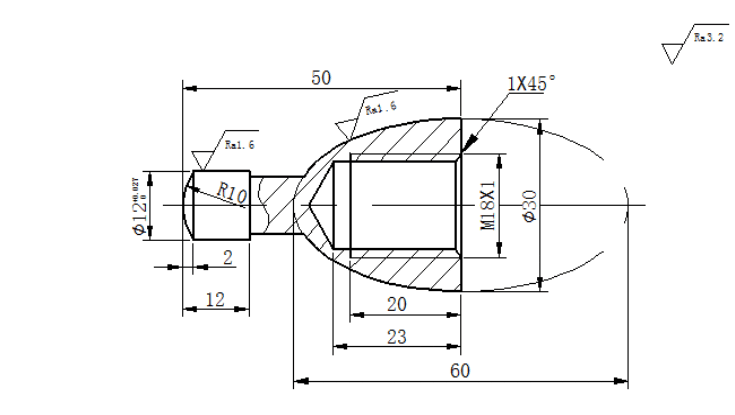

2.1零件图的分析.................................................6

2.2 零件的技术要求分析..........................................7

2.2.1零件的工艺分析............................................7

2.3零件的材料分析...............................................8

2.3.1毛坯选择的原则.............................................9

2.3.2毛坯分析与确定.............................................9

2.4定位基准的选择...............................................9

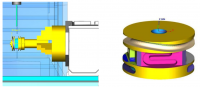

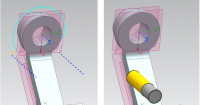

2.5确定装夹方案.................................................9

2.6机床的选择...................................................11

2.7刀具与切削用量的选择.........................................11

2.7.1刀具的选择.................................................11

2.7.2切削用量的选择.............................................12

2.8量具的选择...................................................12

2.8.1背吃刀量的选择.............................................12

2.9夹具的选择...................................................12

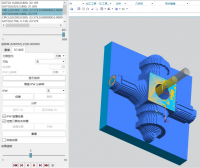

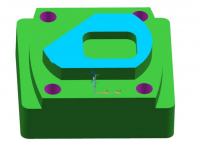

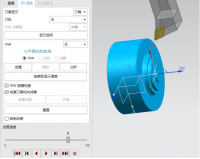

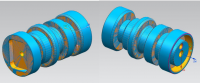

第三章 零件的三维造型..................................................13

3.1三维造型软件的介绍...........................................13

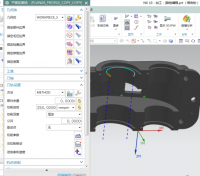

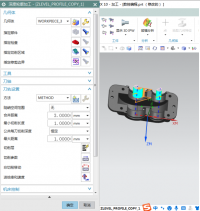

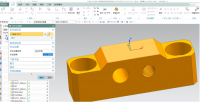

3.2UG软件的介绍................................................13

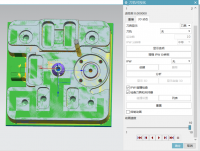

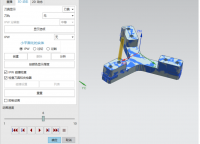

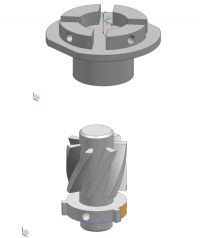

3.3手柄造型过程...............................................14 第四章 工艺卡片的制定.................................................16

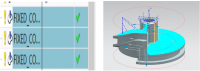

4.1零件加工工艺过程卡..........................................16

4.2数控车削加工工序卡..........................................16

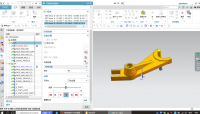

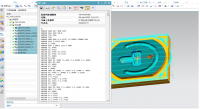

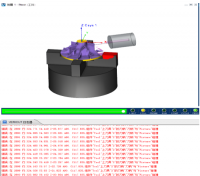

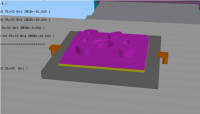

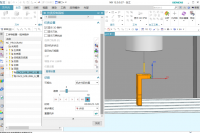

第五章 零件加工程序的编制.............................................22

5.1 数控车床程序编制的基础......................................22

5.2数控车床程序编制的基本方法...................................22

5.3手柄轴数控车削编程..........................................24

第六章 回顾总结......................................................32

6.1课题总结....................................................32

6.2存在问题....................................................32

6.3收获体会....................................................32

致谢..................................................................33

参考文献..............................................................34

成果目录

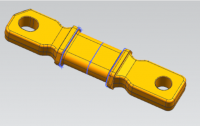

加工零件图

连接轴零件图

成品图

机械加工工艺过程卡片

机械加工工序卡片

参考文献

[1] 赵长旭.<数控加工工艺>.西安电子科技大学出版社,2006

[2]陈宏钧、方向明.<典型零件机械加工生产实例>,机械工业出版社, 2010

[3]韩邦华.<机制工艺与装备>,机械工业出版社,2006

[4] 蔡厚道.<数控机床构造>.北京理工大学出版社,2007

[5] 李华志.<数控加工工艺与装备>. 清华大学出版社,2006

[6] 田春霞.<数控加工工艺>.机械工业出版社,2009

[7] 徐宏海.<数控加工工艺>.化学工业出版社,2005

[8] 陈宏钧.<实用机械加工工艺手册>.机械工业出版社,2003

[9] 杨建明.<数控加工工艺与编程>. 北京理工大学出版社,2006

[10] 傅 莉.<数控车床实际操作手册>.辽宁科学技术出版社,2006

[11]顾京.<数控机床加工程序编制>.机械工业出版社,2009

http://www.bysj1.com/html/6486.html

http://www.bysj1.com/html/6469.html

http://www.bysj1.com/html/6483.html