(代写注塑模毕业设计)轴承盖注塑模具设计

摘 要

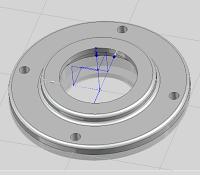

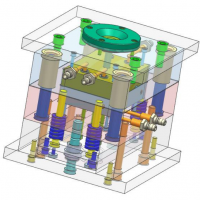

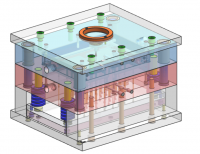

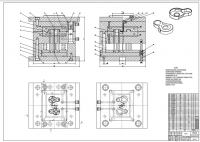

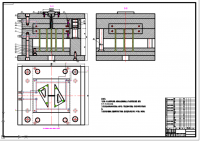

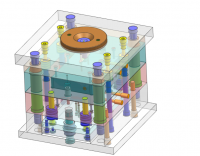

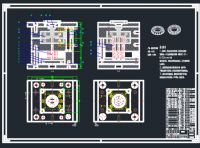

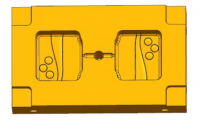

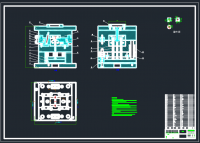

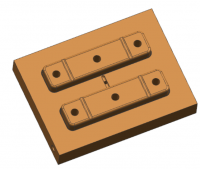

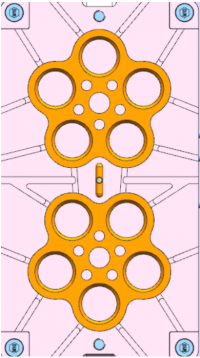

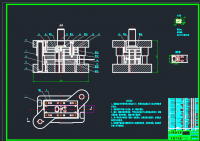

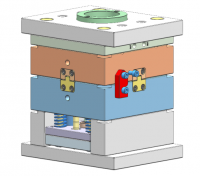

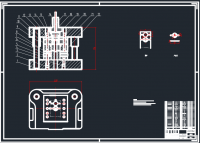

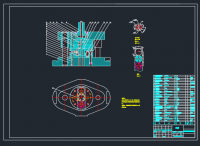

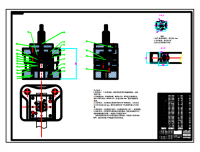

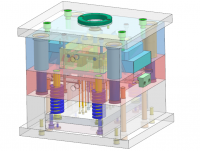

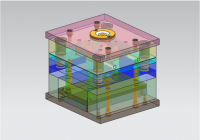

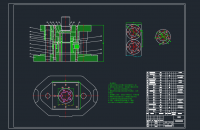

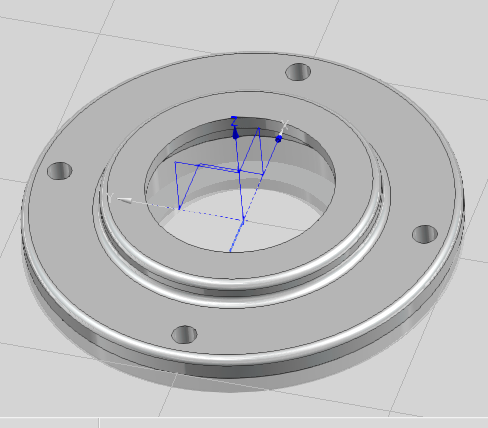

本次论文主要介绍了“轴承盖”零件的塑料模设计过程,这其中包括零件的工艺性分析、模具结构形式的确立、分型面的确定、浇注系统的形式及浇口的设计、零件的结构分析、成型零件的结构设计与计算、模架的选用等内容。通过分析零件的结构,从而设计模具的整体结构也。该零件采用双分型面的点浇口,提高了零件的表面质量。该模具采用一模四腔,采用推件板推出出机构。

按照我国国家标准《全国工农产品(商品、物资)分 类与代码》(GB7635287),模具共分10大类46小类。 塑料模具是其中一个大类。按产值计算,目前我国塑 料模具产值约占全部模具的1/3左右。2000年预计 塑料模具产值可望达到近1〇〇亿元。将各种塑料成形 为制品的模具统称为塑料模具。按照GB7635287,塑 料模具共分7类,它们是:热塑性塑料注塑模、热固性 塑料注塑模、热固性塑料压塑模、挤塑模、吹塑模、真空 吸塑模和其他类塑料模。在各类塑料模具中,注塑模 的量最大,也最有代表性。塑料模具的发展是随着塑料工业的发展而发展的在我国,起步较晚,但发展很快,特别是最近几年, 无论在质量、技术和制造能力上都有很大发展,取得了很大成绩。现在CAD/ CAM/ CAE技术在塑料模的设计制造 上应用已越来越普遍,特别是CAD/ CAM技术的应用 较为普遍,取得了很大成绩。目前,使用计算机进行产 品零件造型分析、模具主要结构及零件的设计、数控机床加工的编程等已成为精密、大型塑料模具设计生产 的主要手段。一些塑料模主要生产企业利用计算机辅 助分析(CAE)技术对塑料注塑过程进行流动分析、冷 却分析、应力分析等,合理选择浇口位置、尺寸、注塑工 艺参数及冷却系统的布置等,使模具设计方案进一步 优化,也缩短了模具设计和制造周期。电子信息工程技术的应用 应用电子信息工程技术进一步提高了塑料模的设 计制造水平。国内一些主要的塑料模生产企业己经实 现了通过客户提供的产品三维信息盘片和网上产品电 子信息来进行预算、报价、设计审定、设计更改等,这不 仅缩短了生产前的准备时间,而且还为扩大模具出口 创造了良好的条件。由于直接利用了用户提供的产品 电子信息,大大缩短了 CAD/CAM的技术准备时间 也相应缩短了模具的设计和制造周期。本设计题目为轴承盖注射模设计,体现了塑料零件的设计要求、内容及方向,有一定的设计意义。通过对该零件模具的设计,进一步加强了设计者塑料模具设计的基础知识,为设计更复杂的塑料模具做好并吸取了更深刻的经验。本设计运用塑料成型工艺及模具设计的基础知识,先分析了工件的成形工艺及模具成形结构对 制件质量的影响。介绍了塑料模具设计时要注意的要点,通过对制件进行工艺分析,可确定制件的成形加工。从控制制件尺寸精度出发,对轴承塑料模具的各主要尺寸进行了理论计算,以确定各工作零件的尺寸,从模具设计到零部件的加工工艺以及装配工艺等进行详细的阐述,并应用CAD进行各重要零件的设计。

关键词:轴承盖 塑料模 发展 计算机技术

Abstract

This paper introduces the "bearing" on the part of the plastic mold design process, including the process of the parts analysis, mold structure is established, parting determine the form and gate gating system design, parts structural analysis, structural design and calculation of molded parts, mold selection and so on. By analyzing the parts of the structure, and thus the overall structural design of the mold as well. This part point gate double parting surface to improve the surface quality of the parts. The four-cavity mold using a mold, using a pusher plate Release mechanism

In accordance with China's national standards, "the country's industrial and agricultural products (commodities, supplies) sub class and code" (GB7635287), the mold is divided into 10 categories, 46 categories. Plastic mold is one of the major categories. According to the output value, the output value of our country's plastic mold is about 1/3 of the whole mold. 2000 is the plastic mold production value is expected to reach nearly 1 1 billion yuan. All kinds of plastic molding products for the mold referred to as plastic mold. In accordance with the GB7635287, plastic mould is divided into seven categories. They are: thermoplastic plastic injection molding, thermosetting plastic injection molding, thermosetting plastic compression mold, extrusion mold, blow molding, vacuum forming mould and other types of plastic mold. In all kinds of plastic mold, injection mold is the largest, but also the most representative. The development of plastic mold is develop along with the development of plastics industry in our country, started late, but it develops very quickly, especially in recent years, both in terms of quality, technology and manufacturing capacity have great development, has made great achievements. Now CAM/ CAE CAD/ technology in the design and manufacture of plastic mold has become more and more common, especially the application of CAM CAD/ technology is more common, has made great achievements. At present, using the computer to produce parts modeling analysis, the main structure and parts of the mold design, CNC machine tool processing programming has become a precision, large-scale plastic mold design and production of the main means. Some plastic mold is mainly manufacturing enterprises using computer aided analysis (CAE) technology of plastic injection molding process of flow analysis, cold but analysis, stress analysis, a reasonable choice of gate location, size, injection molding craft parameters and cooling system layout, so as to make the mould design case further optimization, but also shorten the cycle of mould design and manufacture. The application of electronic information engineering technology in the application of electronic information engineering technology to further improve the level of plastic mold design and manufacturing. Some domestic main plastic mold manufacturing enterprises has by now by providing products 3D information disc and online products electronic information to budget, quotes, design validation, design changes and, which not only shortened the pre production preparation time, but also to expand the export of mold created good conditions. Due to the direct use of the product electronic information provided by the user, the technical preparation time of CAD/CAM is shortened, and the design and manufacturing cycle of the mould is shortened accordingly. This design topic is the bearing cover injection mold design, has manifested the plastic part's design request, the content and the direction, has the certain design significance. Through the design of the parts of the mold, to further strengthen the designers of plastic mold design of the basic knowledge, for the design of more complex plastic mold to do a good job and draw a more profound experience. The design of the use of plastic molding process and mold design of the basic knowledge, the first analysis of the workpiece forming process and the effect of mold forming structure on the quality of parts. This paper introduces the key points of the plastic mould design, through the process analysis of the parts, the forming process of the parts can be determined. From the control of the dimensional accuracy of parts of plastic mould of bearing the main dimensions were calculated and to determine the size of the working parts, from design to mold parts processing and assembly process are described in detail, and the application of CAD for the design of the important parts

Keywords Bearing cap Plastic mould Development Computer technology

目录

绪论 10

1塑料模具概况 10

2课题国内外研究概况 11

3课题研究地主要内容 12

一,塑件成型工艺分析 13

1, 塑件成型特性 13

2, 塑件的结构工艺性 14

3,塑件的生产批量 15

4初选注塑机 16

二,分型面的选择及浇注系统的设计 18

1.分型面的选择 18

2.浇注系统的设计 19

三,模具设计方案的论证 21

1.型腔的布局 21

2.成型零件的结构 21

3.推出机构的确定 22

4.冷却系统的设计论证 23

5.排气结构设计 24

四,主要零部件的设计计算 24

2.模具型腔壁厚的确定 25

3. 模具型腔模板总体尺寸的确定 25

4.标准模架的确定 26

五,注射机有关参数的校核 26

1.模具闭合高度的确定 26

2模具闭合高度的校核 27

3.模具安装部分的校核 27

4模具开模行程的校核 27

5注塑量的校核 27

6锁模力的校核 28

六,模具总装配图 29

设计小结 30

致谢 31

参考文献 32

参考文献

[1] 赵蓓蓓. 初探塑料模具材料现状及发展方向[J]. 科技资讯, 2009, (34).

[2] 孙安垣, 闫烨, 杨超谈, 桂春. 我国改性塑料行业的发展前景[M].《工程塑料应用》杂志社, 2010, 11(2):83-87.

[3] 伍先明,王群. 塑料模具设计指导[M]. 北京: 国防工业出版社, 2006.

[4] 朱光力, 万金保. 塑料模具设计[M]. 北京: 清华大学出版社, 2003.

[5] 杨明锦, 陆长征. 结构型与复合型导电塑料研究进展[J]. 塑料, 2005, 34(3); 15-18.

[6] 陈勇, 官建国, 谢洪泉. 导电塑料的研究进展[J]. 弹性体, 2008, 18(2).

[7] 彭竹琴. 塑料导电改性原理及应用[J]. 绝缘材料, 2004(06).

[8] 赵幸, 王立新. 复合型导电塑料的发展[J]. 塑料科技, 2002(2).

[9] 韩小雪, 季静. 纤维增强塑料(FRP)在混凝土结构中的应用——FRP材料性能与发展[J]. 华南理工大学学报(自然科学版), 2002, 30(2).

[10] 田水, 朱墩. 纤维增强塑料(FRP)在结构加固工程中的应用[J]. 建筑结构,