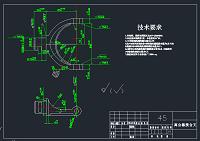

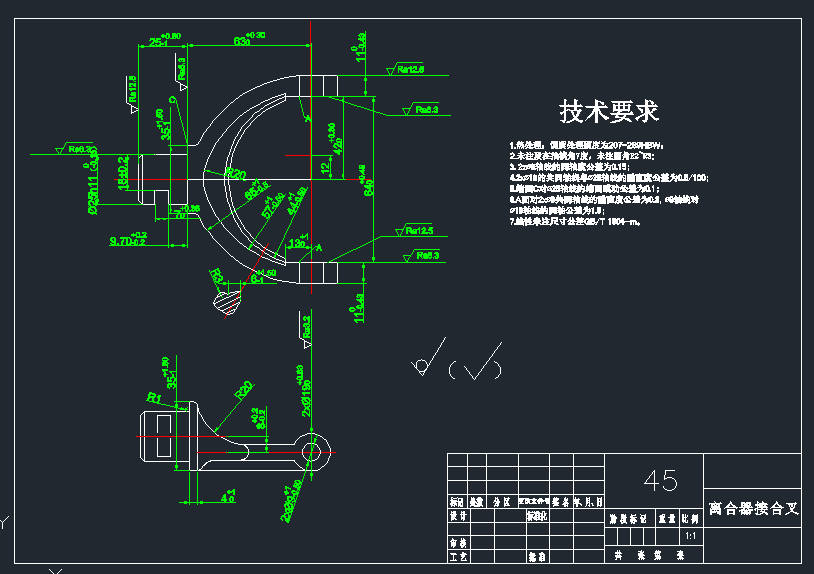

离合器接合叉工艺工装设计

中 文 摘 要:

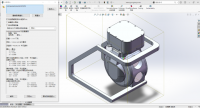

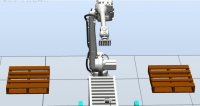

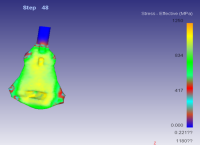

离合器接合叉零件的主要加工表面是孔和圆柱表面,外圆表面加工根据精度要要求可选择车削和磨削。孔加工方法的选择比较复杂,需要考虑零件的结构特点、孔径大小、长径比、精度和粗糙度要求以及生产规模等各种因素。对于精度要求较高的孔往往还要采用几种不同的方法顺次进行加工。本次设计,为了保证孔的精度和表面粗糙度,需要粗车,半精车,精车,钻孔,铰孔等等加工工序。

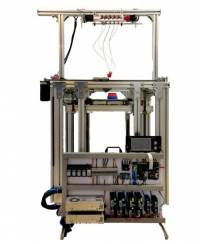

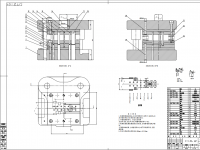

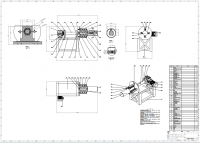

在机床上对零件进行机械加工时,为保证工件加工精度,首先要保证工件在机床上占有正确的位置,然后通过夹紧机构使工件在正确位置上固定不动,这一任务就是由机床夹具完成。对于单件、小批量生产,应尽量使用通用夹具,这样可以降低工件的生产成本。但是由于通用夹具适用各种工件的装夹,所以夹紧时往往比较费时间,并且操作复杂,生产效率低,也难以保证加工精度,为此需设计专用夹具。

关键词:工艺设计、基准选择、切削用量、定位误差

Clutch engagement fork process tooling design

ABSTRCT:

Clutch engagement fork main processing surface for hole and outer annulus surface. The outer annulus face work needs to request according to the precision to be possible to choose the turning and the grinding. The hole processing method's choice is quite complex, needs to consider the components the unique feature, the aperture size, the length to diameter ratio, the precision and roughness request as well as the scale of production and so on each kind of factor. Often must use several different methods regarding the accuracy requirement high hole to carry on the processing in order. This design's cylinder, will pass through half finished boring, the finished boring, the fine articulation and the trundle successively for the guarantee hole's precision and the surface quality and so on five working procedure processings.

When the engine bed carries on the machine-finishing to the components, is guaranteed that the work piece working accuracy, first needs to guarantee the work piece holds the correct position on the engine bed, then causes the work piece in the correct position through the clamp organization fixed motionless, this duty is completes by the engine bed jig. Regarding the single unit, the small batch production, should use the universal jig as far as possible, like this may reduce the work piece the production cost. But because the universal jig is suitable each kind of work piece the attire to clamp, therefore time clamp often compares spends the time, and operates complex, the production efficiency is low, also guarantees the working accuracy with difficulty, for this reason must design the unit clamp.

Key word: Craft, datum, cutting specifications, localization datum, position error.

目录

第一章 零件的分析……………………………………………………..9

1.1零件的作用………………………………………………………..9

1.2零件的工艺分析…………………………………………………..9

第二章 工艺规程………………………………………………………..10

2.1毛坯和材质………………………………………………………..10

2.2工艺路线和加工方法……………………………………………..10

2.3机床和刀具………………………………………………………..12

2.4确定加工余量和尺寸……………………………………………..12

2.5确定切削余量和工时……………………………………………..13

第三章 夹具设计………………………………………………………..15

3.1夹具的作用………………………………………………………..15

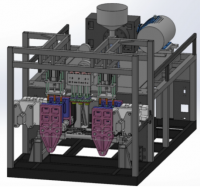

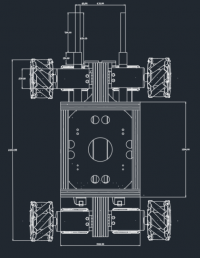

3.2夹具的设计………………………………………………………..15

3.3夹具的装配………………………………………………………..16

第四章 设计小结…………………………………………………………..18

参考文献……………………………………………………………………18

参考文献

《切削用量简明手册》

《机械加工工艺手册》 李洪

《机械制造工艺设计简明手册》

《实用机械加工工艺手册》陈宏钧

《机床夹具设计手册》王光斗,王春福