拨叉零件的加工及夹具设计

目录

摘要

第一章 零件的分析·····························

··················8

1.1拨叉的工艺分析·····························

························8

1.2拨叉的工艺要求·····························

························8

第二章 工艺规程设计····························

·················10

2.1 零件的偏差,加工余量,工序尺寸及毛坯尺寸的确定·············

·······10

2.1.1毛坯的结构工艺要求·························

····················10

2.1.2拨叉的偏差计算···························

······················11

2.2确定表面加工方案····························

·······················12

2.3定位基准································

···························12

2.3.1粗基准的选择····························

·······················12

2.3.2精基准的原则····························

·······················12

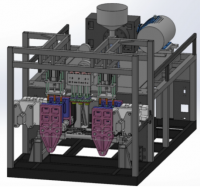

2.4加工工艺过程······························

·························14

2.5工艺路线的拟订·····························

························14

2.5.1加工阶段的划分···························

······················14

2.5.2加工工艺路线方案的比较·······················

··················15

2.6确定切削用量及基本工时·························

····················16

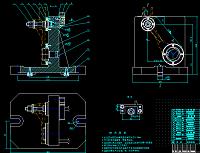

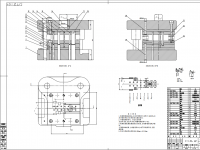

第三章 夹具的设计·····························

··················22

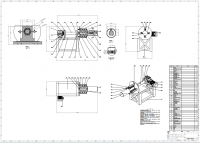

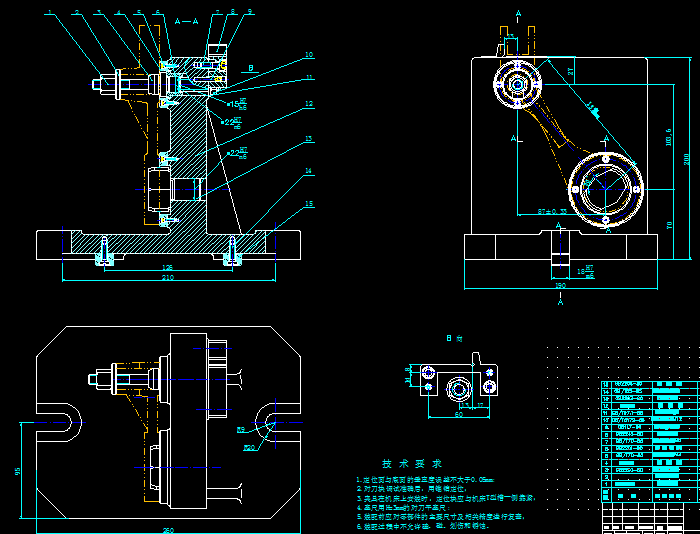

3.1镗孔夹具设计······························

·························22

3.1.1研究原始质料····························

·······················22

3.1.2定位、夹紧方案的选择························

···················23

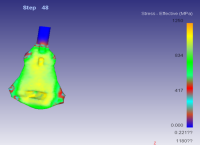

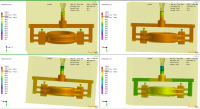

3.1.3切削力及夹紧力的计算························

···················23

3.1.4误差分析与计算···························

······················25

3.1.5零、部件的设计与选用························

···················26

3.1.6夹具设计及操作的简要说明······················

·················27

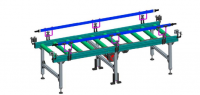

3.2铣槽夹具设计······························

·························27

3.2.1研究原始质料····························

·······················27

3.2.2定位基准······························

·························27

3.2.3切削力及夹紧分析计算························

···················28

3.2.4误差分析与计算···························

······················29

3.2.5零、部件的设计与选用························

···················30

3.2.6夹具设计及操作的简要说明······················

·················31

小结···································

······························31

致谢····································

······························32

参考文献··································

·····························33

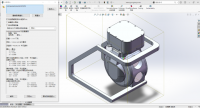

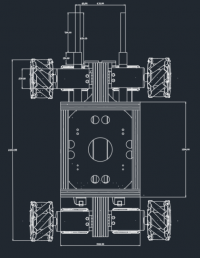

第一章 零件的分析

1.1拨叉的工艺分析

拨叉是一个很重要的零件,因为其零件尺寸比较小,结构形状较复杂,但其加工孔和底

面的精度要求较高,此外还有小头孔端要求加工,对精度要求也很高。拨叉的底面、大

头孔上平面和小头孔粗糙度要求都是,所以都要求精加工。其小头孔与底平面有垂直度

的公差要求,拨叉底面与大头孔上平面有平行度公差要求,所要加工的槽,在其槽边有

平行度公差和对称度公差要求等。因为其尺寸精度、几何形状精度和相互位置精度,以

及各表面的表面质量均影响机器或部件的装配质量,进而影响其性能与工作寿命,因此

它们的加工是非常关键和重要的。

1.2拨叉的工艺要求

一个好的结构不但要应该达到设计要求,而且要有好的机械加工工艺性,也就是要有加

工的可能性,要便于加工,要能够保证加工质量,同时使加工的劳动量最小。而设计和

工艺是密切相关的,又是相辅相成的。设计者要考虑加工工艺问题。工艺师要考虑如何

从工艺上保证设计的要求。

参考文献:

[1] 倪森寿,吕伟文,谈向群 机械技术基础[M]北京:人民邮电出版社,2009

[2] 倪森寿 机械制造工艺与装备[M]北京:化学工业出版社,2008

[3] 薛源顺 机床夹具设计[M]第二版,北京:机械工业出版社,2003

[4] 李昌年 机床夹具与制造[M] 北京:机械工业出版社,2007

[5] 夏碧波 机械制造技术[M]北京:中国电力出版社,2008

[6] 李洪 机械加工工艺手册[M]北京:北京出版社版,2003

[7] 刘登平 机械制造工艺及机床夹具设计[M]北京:北京理工大学出版社,2001

[8] 马振福 机械制造技术[M]北京:机械工业出版社,2005

[9] 张佳 机械制造装备设计[M]北京:机械工业出版社,2003

[10]赵家齐 机械制造工艺学课程设计指导书[M]北京:机械工业出版社,2000

http://www.bysj1.com/ http://www.bysj1.com/html/4526.html

http://www.bysj1.com/html/4510.html

http://www.bysj1.com/html/4506.html

http://www.bysj1.com/html/4483.html

http://www.bysj1.com/html/4483.html

http://www.bysj1.com/html/4470.html

http://www.bysj1.com/html/4464.html