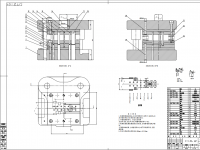

杠杆支撑”零件的工艺工装设计(12+0.12槽铣夹具

目 录

第一章 绪论……………………………………....9

2.毕业设计说明书正文····························

..…11

第二章 零件的分析·····························.

·11

2.1 零件的作用······························

·····. 12

2.2 零件的工艺分析····························

··.·12

第三章工艺规程设计……………………………………..…12

3.1 确定毛培外形尺寸 ……………………………..…12

3.2 定位基准的选择························……….…

.13

3.2.1 粗基准的选择

······················……………...13

3.2.2精基准的选择················…………………………13

3.3 拟定工艺路线··························……….

….13

3.3.1 工艺路线一······················………………

…14

3.3.2 工艺路线二·························………

……14

3.3. 工艺方案的分析与比较················………·14

3.34 确定刀具选择……………………………………………….15

3.35 量具选择…………………………………………….16

第四章 机械加工余量.工序尺寸及毛坯尺寸的定····16

第五章 确定切削用量及工时定额··············.17

5.1专用夹具设计······························

······…..·18

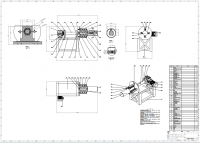

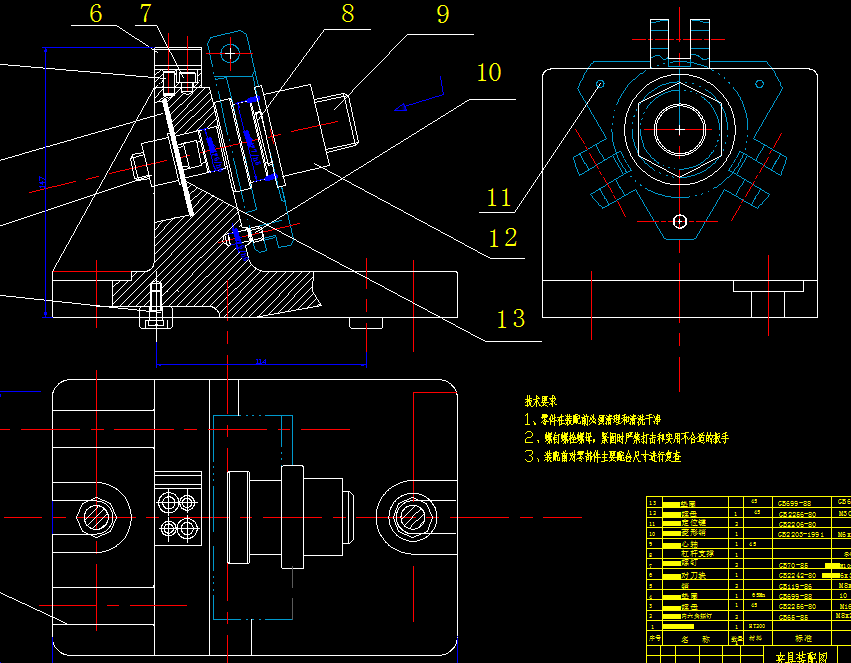

5.1.1 夹具的功能与组成··················…………….24

5.1.2 夹具设计的一般步骤·············……………….25

5.1.3 绘制夹具装配图····················……………..26

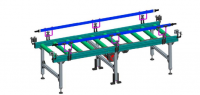

5.2 铣床夹具的设计···························…

……··27

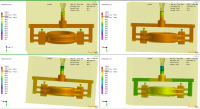

5.3 切削力及夹紧力计算·························

…….28

5.4定位误差分析······························

·····………29

第六章、 参考文献·························

········30

第七章 毕业论文小结···························

··31

第八章、 致信·······························

········32

第九章 外文翻译·····························

·····.33

第一章 绪论

随着国内外经济形新形势的发展,我国的新会计改革制度也随之面临着新的发展趋势近

二十年来,财政部对会计制度进行了重大改革,取得了一系列的成果,新会计制度的发

布标志着我国会计核算制度走向成熟. 也是我国会计改革. 的又一新高潮。它对规范我

国企业会计核算行为. 真实、完整地反映我国的财务. 状况、经营成果和现金流量. 提

高经济单位的会计信息质量具有深远的意义*本表随毕业设计论文一起上交。

记协制造业是制造具有一定形状位置和尺寸的零件和产品,并把它们装备成机械装备的

行业。机械制造业的产品既可以直接供人们使用,也可以为其它行业的生产提供装备,

社会上有着各种各样的机械或机械制造业的产品。我们的生活离不开制造业,因此制造

业是国民经济发展的重要行业,是一个国家或地区发展的重要基础及有力支柱。从某中

意义上讲,机械制造水平的高低是衡量一个国家国民经济综合实力和科学技术水平的重

要指标。

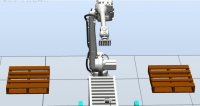

杠杆支撑加工工艺规程及其夹具设计是在学完了机械制图、机械制造技术基础、机械设

计、机械工程材料等进行课程设计之后的下一个教学环节。正确地解决一个零件在加工

中的定位,夹紧以及工艺路线安排,工艺尺寸确定等问题,并设计出专用夹具,保证零

件的加工质量。本次设计也要培养自己的自学与创新能力。因此本次设计综合性和实践

性强、涉及知识面广。所以在设计中既要注意基本概念、基本理论,又要注意生产实践

的需要,只有将各种理论与生产实践相结合,才能很好的完成本次设计。

本次设计水平有限,其中难免有缺点错误,敬请老师们批评指正。

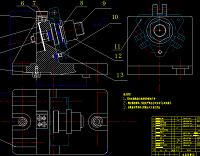

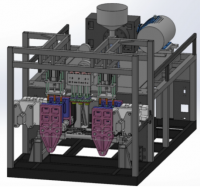

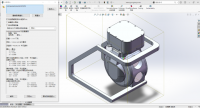

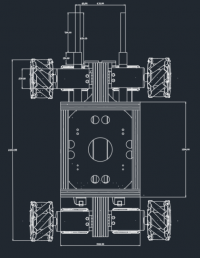

摘要: 本设计主要围绕发动机杠杆支撑的工艺规程和专用夹具设计进行研究,其内容

包括了解杠杆结构,确定杠杠支撑的生产类型,相关的技术要求。在此基础上,选择毛

坯,确定毛坯的尺寸公差和机械加工余量,绘制毛坯图。CAD绘制标准零件图,并在认

真详细分析零件图后,进行基准的选择,制定了表面加工方法,划分加工阶段,根据生

产类型确定工序的集中和分散,合理地安排工序,编排合适的工艺路线;进行详细的大

量计算,包括:加工余量、工序尺寸和公差的确定、切削用量的计算及时间定额的计算

。从而制定出一套合理的机械加工工艺卡片和机械加工工序卡片。

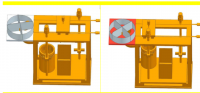

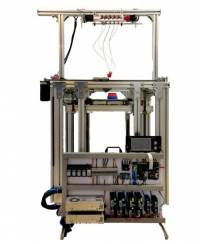

第二部分的设计是本课题的重点也是难点,主要围绕专有钻床类夹具的设计,用卧

式双面中心铣槽,为铣断面打中心孔这道工序设计一钻床夹具。首先明确夹具设计的主

要任务,通过确定定位元件,导向装置,夹紧机构得出夹具的结构方案,查阅相关国家

标准,绘画夹具装配图。

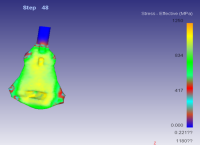

本课题研究的发动机曲轴应用在汽车发动机中,

总之,杠杠支撑加工工艺的安排以及专用夹具的设计是一项非常复杂的高难度工作

,。它是一种需大批量生产的零件。且技术要求比较高,为了确保产品的质量和水平,

设计工作按照科学的程序进行,分清主次,合理取舍。

关键词:杠杠支撑;加工工艺;工艺规程;制造工艺;夹具

Abstract: The design was studied that was focused on transmission

with the shift fork of the protocols and proprietary drilling fixture

design, whose contents were included that the use of blades, the

blades type of production and the relevant technical requirements. On

this basis, the rough was chosen, and the size of the rough was

determined, and the mechanical allowances were determined. A rough

map was drawn. After carefully detailed analysis of the parts map,

the benchmark was chosen, the development of surface processing

methods was determined, and the demarcation of the processing stages

was divided. According to the production process the type of

centralization and decentralization was determined, the process was

reasonably arranged, and the order and orchestrates a suitable

process line were set up. Then some detail was calculated, such as

allowance, processes size and the determination of tolerance. The

amount of calculation and the calculation of the fixed time was cut.

Thus a set of reasonable card processing machinery and mechanical

processes cards were drawn up.

The second part of the design was the focus of this issue which was

difficult, who was mainly centered on proprietary drilling fixture

design, Z525-use vertical drilling, drilling screw hole design

process by which a drilling fixture. Firstly fixture was designed to

clear the major tasks identified by positioning components, guidance

devices, clamping body fixture structure, access to the relevant

national standards, painting fixture assembly.

The study of the subject transmission blades was used in the

transmission gearbox shift agencies. Through the design of the

transmission plectrum shift gearbox bodies changed stalls, thus it

changed the speed of automobile.

This paper transmission plectrum design of technical rules,

transmission truly achieved the change stalls and shift function,

against drilling fixture design, realization of the drilling screw

hole of this procedure.

In short, the design of transmission plectrum was a complex task. It

was the typical products in mass production. To ensure the quality of

products and the level of design the work must be produced in

accordance with the scientific procedure, prioritize, reasonable

choice

Kywords: rankshaft,;achining,;echnical rules;manufacturing

technology;ixtur

参考文献

1.《切削用量手册》 艾兴、肖诗纲编 北京:机械工业出版社

2.《机械制造工艺设计简明手册》李益明编 机械工业出版社

3.《机床夹具设计》 哈尔滨工业大学 上海科学技术出版社

4. 《切削用量简明手册》

5.《金属机械加工工艺人员手册》 上海科学技术出版社

6.《机制工艺及装备课程设计指导》倪森寿 化学工业出版社

7<<机械机床手册>> 上海科学出版社

8《机械制图》 哈尔滨大学出版社

9《机械设计》 北京大学出版社

10《机械加工紧固件手册》

http://www.bysj1.com/ http://www.bysj1.com/html/4526.html

http://www.bysj1.com/html/4510.html

http://www.bysj1.com/html/4506.html

http://www.bysj1.com/html/4483.html

http://www.bysj1.com/html/4483.html

http://www.bysj1.com/html/4470.html

http://www.bysj1.com/html/4464.html