BW-200型泥浆泵曲轴箱盖铸造工艺设计

摘要:介绍了BW-200型泥浆泵曲轴箱盖铸造工艺尧浇注系统。内容主要有曲轴箱盖体铸造方案选择、箱盖铸造工艺参数的设计。包括造芯,造型,铸造方法,凝固原则及浇注位置,分型面,砂箱中的铸件数量及排列,砂型数量,工艺参数等。

关键词:铸造工艺;BW-200型曲轴箱盖;浇注系统

1. 泥浆泵的简介

泥浆泵,是指在钻探过程中向钻孔里输送泥浆或水等冲洗液的机械。泥浆泵是钻探设备的重要组成部分。

泥浆泵在常用的正循环钻探中﹐它是将地表冲洗介质──清水﹑泥浆或聚合物冲洗液在一定的压力下,经过高压软管﹑水龙头及钻杆柱中心孔直送钻头的底端,以达到冷却钻头、将切削下来的岩屑清除并输送到地表的目的。

常用的泥浆泵是活塞式或柱塞式的,由动力机带动泵的曲轴回转,曲轴通过十字头再带动活塞或柱塞在泵缸中做往复运动。在吸入和排出阀的交替作用下,实现压送与循环冲洗液的目的。

目录

1.泥浆泵简介······················································5

1.1 BW-200型泥浆泵简介········································5

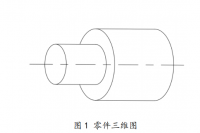

2. BW-200型泥浆泵曲轴箱盖的工艺分析······························6

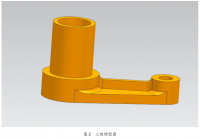

2.1结构图·····················································7

2.2工作环境性能要求分析·······································7

3. BW-200型泥浆泵曲轴箱盖选材·····································8

3.1. 球墨铸铁的金相组织,性能特点,牌号,技术要求··············8

3.2. 灰铸铁的金相组织,性能特点,牌号,技术要求·················· 11

3.3. 材料确定················································· 18

4.灰铸铁的熔炼····················································18

4.1熔炼的概念·················································18

4.2灰铸铁的熔炼工艺方式·······································19

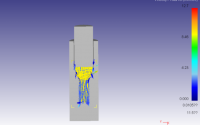

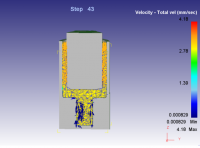

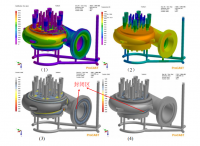

5.浇筑系统的设计··················································23

5.1.金属液的充型···············································23

5.1.1影响金属液充型能力的因素·····························23

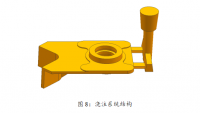

5.2.浇筑系统各部分的结构形式···································24

5.2.1浇口·················································25

5.2.2直浇道···············································27

5.2.3横浇道···············································29

5.2.4内浇道···············································29

5.2.5浇筑系统的选择·······································29

5.2.6灰铸铁件浇注时间的确定·······························30

5.2.7阻流组元截面积的计算几个组元的直接比例关系的确定·····31

5.3.灰铸铁铸件各部分浇注尺寸···································31

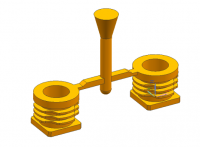

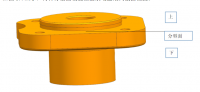

5.4. 灰铸铁工件冒口尺寸········································32

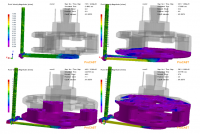

6. 铸件凝固控制与冒口设计·········································32

6.1灰铸铁的凝固特点···········································32

6.2 铸件的收缩及收缩缺陷·······································33

6.2.1铸件的收缩···········································33

6.3 冒口补缩原理及补贴设计·····································33

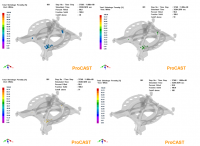

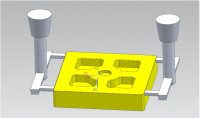

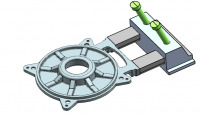

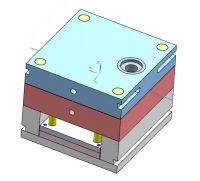

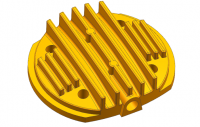

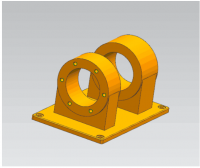

7.BW-200箱盖的铸造工艺设计········································34

7.1 铸造工艺方案的确定·········································34

7.1.1零件结构的铸造工艺性·································34

7.1.2铸件浇注位置的选择···································35

7.1.3铸型分型的选择·······································35

7.2 铸造工艺设计参数···········································36

7.3 砂芯设计···················································40

7.3.1砂芯的固定与定位······································40

7.3.2芯头的尺寸············································41

7.3.3芯骨设计··············································41

7.3.4砂芯的排气············································41

8.灰铁铸件缺陷 ····················································42

8.1铸件缺陷···················································42

8.2灰铸铁件氧化夹渣缺陷特征以及防止方法·······················42

8.3灰铸铁件缩松缺陷特征以及防治方法···························42

8.4灰铸铁件气孔气泡缺陷特征以及防治方法·······················43

8.5球化不良和求花衰退的特征 ································43

9.铸件工艺卡······················································45

小结······························································47

参考文献··························································48

参考文献

[1]孟庆桂,铸工实用技术手册,江苏科学技术出版社,2002年1月,P52、P56、P57、P65、P68、P72、P81、P141、P142、P144;

[2]林勃,砂型铸造工艺学,机械工业出版社,1992年10月,P398、P400;

[3]王君卿,铸造手册,机械工业出版社,2004年5月,P149、P203、P204;

[4]王晓江,铸造合金及其熔炼,机械工业出版社,2011年;

[5]曲卫涛,铸造工艺学,西北工业大学出版社,1996年;

[6]李弘英,铸造工艺设计,机械工业出版社,2005年, P27;

[7]刘瑞玲 范金辉,铸造实用数据速查手册, 机械工业出版社,2006年;

[8]曹瑜强,铸造工艺及设备,机械工业出版社,2012年;

[9]铸造工程师手册编写组,铸造工程师手册,机械工业出版社,2002年。

www.bysj1.com www.bysj1.com/html/4750.html www.bysj1.com/html/4749.html www.bysj1.com/html/4748.html www.bysj1.com/html/4747.html