ZG35CrMo行星架的铸造工艺设计

摘要:本次为行星架的铸造工艺,行星架材质为为 ZG35CrMo,行星架主要采用铸造成型的方式,在浇注过程中对质量要求较高。行星架的得铸造有以下难点:材料为高强度合金铸钢,治炼困难;铸件上的连接筋部分较厚,容易形成缩松、缩孔等铸造缺陷,所以在制作工艺的时候,必须保证铸件的尺寸精度和浇注的铸造质量。同时减少对环境的污染和控制制造成本。

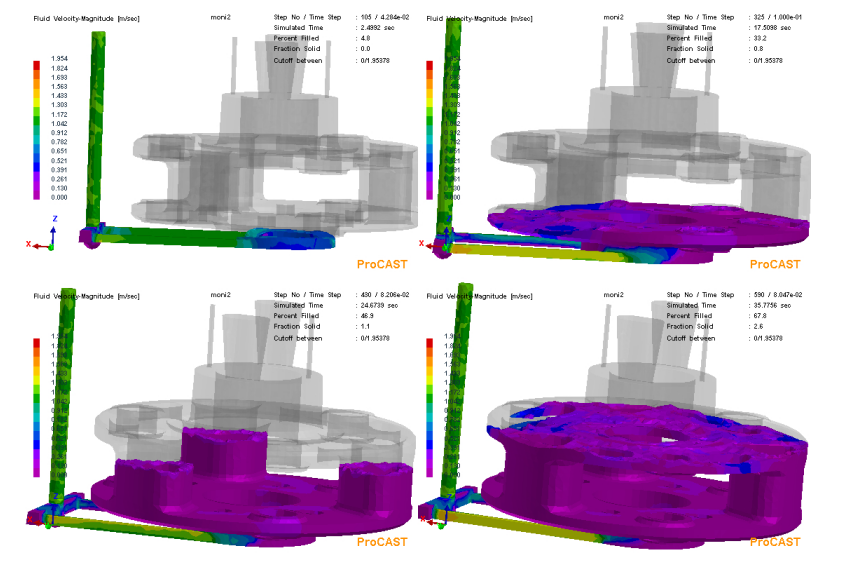

在对行星架零件的分析时,并对铸件的尺寸进行分析。根据材料的特点确定造型材料为酯硬化水玻璃砂,由于行星架的尺寸较大,浇注时由于钢液的冲击速度较大会导致砂型的损坏,所以选用稳定性较好的底注式浇注系统。在铸造设计的过程中用到仿真软件Procast进行模拟。

关键词:行星架 酯硬化水玻璃砂 底注式浇注系统

Casting Process Design of ZG35CrMo Planetary Frame

Abstract: This is the casting process of the planetary frame. The material of the planetary frame is ZG35CrMo. The planetary frame is mainly cast and formed, and the quality requirements are higher in the pouring process.

The casting of the planetary frame has the following difficulties: the material is high strength alloy cast steel, which is difficult to smelt;The connecting bar part of the casting is thicker, and it is easy to form casting defects such as shrinkage porosity and shrinkage cavity. Therefore, in the production process, it is necessary to ensure the dimensional accuracy and casting quality of the casting.

At the same time to reduce environmental pollution and control the manufacturing cost.

In the analysis of the planetary frame parts, and the size of the casting is analyzed.According to the characteristics of the material, the molding material is determined to be ester hardened sodium silicate sand. Because the size of the planetary frame is large, the impact velocity of molten steel during casting is larger, which leads to the damage of the sand mold, so the bottom pouring system with better stability is selected.In the process of casting design, the simulation software ProCAST is used for simulation.

Key words: planetary frame ester hardened sodium silicate sand bottom pouring system

目 录

摘要 ................................................................................................................................... 1

一、零件的特点与工作环境分析 .................................................................................... 2

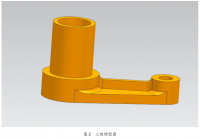

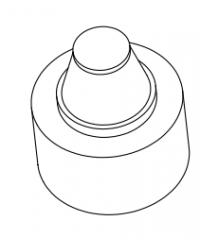

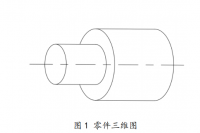

(一)零件结构特点分析 ................................................................................................. 2

(二)零件用途分析 ......................................................................................................... 3

1零件工作环境分析 ............................................................................................... 3

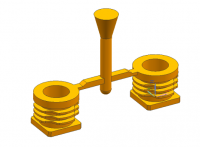

2行星架的结构 ....................................................................................................... 4

二、造型材料选择.............................................................................................................. 4

(一)造型材料的选择要求 ............................................................................................. 4

(二)造型材料的选用 ..................................................................................................... 4

三、铸造工艺的选择.......................................................................................................... 5

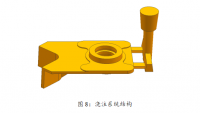

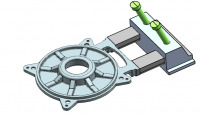

(一)浇注位置的确定 ..................................................................................................... 5

(二)分型面的选择 ......................................................................................................... 5

(三)铸造工艺参数........................................................................................................... 6

1铸件尺寸公差 ......................................................................................................... 6

2铸件的重量公差 ..................................................................................................... 7

3机械加工余量 ......................................................................................................... 7

4铸造收缩率 ............................................................................................................. 8

5起模斜度 ................................................................................................................. 8

6铸件最小壁厚和最小铸出孔 ................................................................................. 8

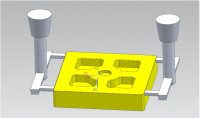

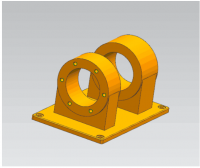

(四)砂芯的设计 ............................................................................................................. 9

1砂芯的安装位置及形状 ........................................................................................ 9

2芯骨设计 ............................................................................................................... 11

3砂芯排气 ............................................................................................................... 11

四、铸件的浇注系统设计................................................................................................ 11

(一)浇注系统选择 ....................................................................................................... 11

(二)浇注时间计算 ....................................................................................................... 11

(三)包孔截面积计算 ................................................................................................... 12

(四)浇注系统各单元截面积计算................................................................................. 13

(五)浇注系统的校核..................................................................................................... 14

(六)浇口杯的设计......................................................................................................... 16

五、铸造工艺设计优化.................................................................................................... 15

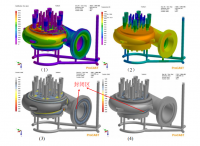

(一)网格划分 ............................................................................................................... 15

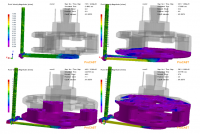

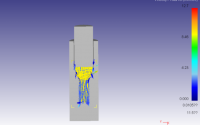

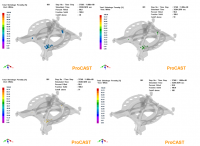

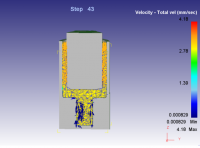

(二)铸造参数设定及模拟 ........................................................................................... 16

(三)模拟结果分析 ....................................................................................................... 17

1充型速度分析......................................................................................................... 17

2铸造缺陷和工艺优化............................................................................................. 18

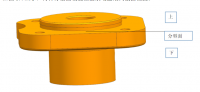

六、补缩系统设计............................................................................................................ 19

(一)冒口的设计 ........................................................................................................... 19

(二)冷铁的设计 ........................................................................................................... 20

1冷铁的选择 ........................................................................................................... 20

2冷铁的位置 ........................................................................................................... 20

3冷铁尺寸计算 ....................................................................................................... 20

(三)初步优化结果与分析 ........................................................................................... 22

七、铸造工艺装备 .......................................................................................................... 23

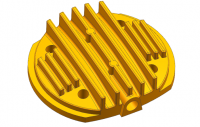

(一)模样的设计 ........................................................................................................... 23

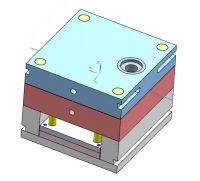

(二)砂箱的设计 ........................................................................................................... 23

(三)芯盒设计 ............................................................................................................... 24

参考文献 ................................................................................................................................ 25

参考文献

1) 中国机械工程学会铸造分会. 铸造手册:第 5 卷,铸造工艺[M].2版. 北京:机械工业出版社,2011.5

2) 魏华胜.铸造工程基础 [M].北京:机械工业出版社,2002

3) 刘文川, 向敬成. 大型铸件有效浇注时间的计算[J]. 大型铸锻件. 2000 年第 4 期( 总第 90 期) (5) 杜西灵 杜磊编著.铸造实用技术问答[M].机械工业出版社,2007 年 05 月第 1 版.

4) 崔令江,郝滨海.材料成型技术基础[M].北京:机械工业出版社,2003.

5) 王晓江.铸造合金及其熔炼[M].北京:机械工业出版社,1999

6)曹瑜强.铸造工艺及设备[M].北京:机械工业出版社,2016.1.

7) 陈永龙,刘文川.大型球墨铸铁件铸造工艺的优化设计[J]. 热加工工艺, 2011年第40卷第9期:195-199页

8) 李日.铸造工艺仿真 ProCAST 从入门到精通[M]. 中国水利水电,2010 年 01 月第 1 版

9) 王树成.压边浇冒口对铸件质量的影响[J].现代铸铁,2002年第 46 卷第 2 期:46-47 页