HT200底座的铸造工艺设计

摘要:

随着我国机械工业生产的不断发展,铸造工艺技术已成为机械工人和技术人员在技术革新中的一项重要任务。掌握铸造工艺技术知识是现代机械类专业学生必不可少的。

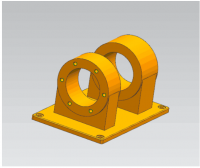

本文通过对一个简单底座零件结构分析,并对其确定工艺方案,合适的工艺方案可以满足精度要求和各零件。根据整体的结构确定铸造工艺参数的。从零件的分析到最后浇注系统的设计,都经过了一系列的思考和分析。

关键字:底座铸造工艺,砂芯,浇注系统

Abstract:

With the continuous development of China's machinery industry, foundry technology has become a major task of mechanical workers and technicians in technical innovation. Master knowledge of casting process is essential to modern mechanical engineering students.

In this paper, a simple structure of the base parts is analyzed, and its determination process, the appropriate process can meet the accuracy requirements and parts. Determining the casting process parameters according to the overall structure. From the analysis of parts to the design of the casting system, it has been a series of thinking and analysis.

Key words: base casting technology, sand core, casting system

目录

一、绪论 ·························································· 1

1.1、工艺设计的概念 ··············································· 1

1.2、设计依据······················································· 1

1.3、铸造方法的确定················································ 1

1.4、铸造生产的特点················································ 1

二、工艺的审核····················································· 2

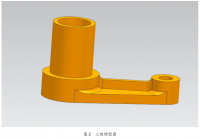

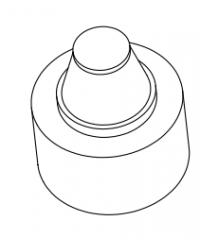

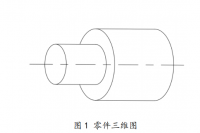

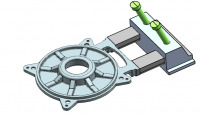

2.1、零件的分析···················································· 2

2.2、零件的图样分析················································ 2

2.3、零件的结构工艺性·············································· 4

三、工艺设计······················································· 4

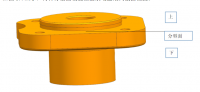

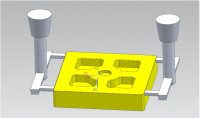

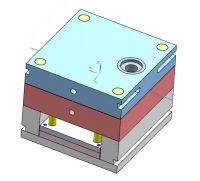

3.1确定工艺方案···················································· 4

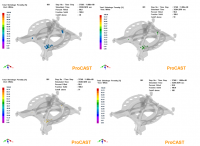

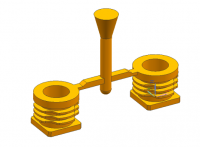

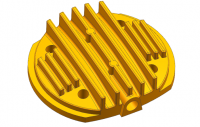

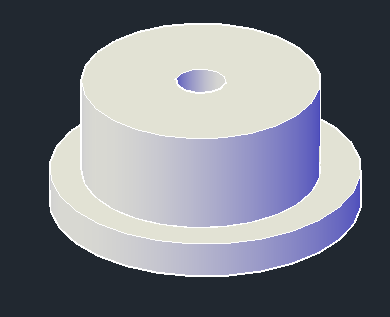

3.2砂芯设计······················································· 12

3.3铸造工艺设计参数的确定········································· 14

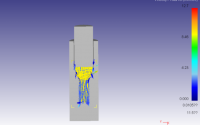

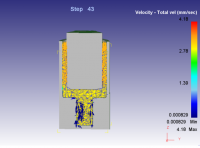

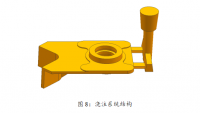

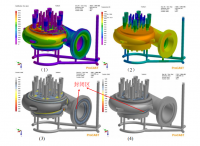

3.4浇注系统设计··················································· 17

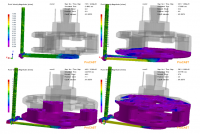

四、预计生产该铸件可能产生的缺陷及防止措施·························25

4.1、缩孔、缩松、疏松···············································25

4.2、冲砂··························································25

4.3、浇不到························································26

4.4、砂芯未充分烘干················································26

4.5、飞翅··························································26

4.6、冷裂·························································· 26

4.7、毛刺·························································· 27

五、参考文献······················································· 28

六、心得与致谢···················································· 29

参考文献

[1] 凌爱林,金属工艺学[M] 北京:机械工业出版社,2001.

[2] 王晓江,铸造合金及其熔炼[M]. 北京:机械工业出版社,1999.

[3] 张世昌,李旦,高航. 机械制造技术基础[M]2版. 北京:高等教育出版社.

[4] 刘喜俊.,铸造工艺学[M]. 北京:机械工业出版社,1999.

[5] 王文清,李魁盛. 铸造工艺学[M]. 北京:机械工业出版社,2005.

[6] 吴宗泽,罗圣国. 机械设计课程设计手册[M]3版. 北京:高等教育出版社.

[7] 魏华盛.,铸造工程基础[M]. 北京:机械工业出版社,2002.

[8] 崔令江,郝滨海. 材料成型技术基础[M]. 北京:机械工业出版社,2003.

[9] 曹瑜强,铸造工艺及设备[M]2版. 北京:机械工业出版社,2008.

[10] 中国机械工程学会铸造分会,铸造手册:第5卷铸造工艺[M].2版 北京:机械工业出版社,2005.

http://www.bysj1.com/cat.asp?id=22&page=14

http://www.bysj1.com/cat.asp?id=25&page=13