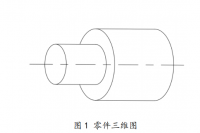

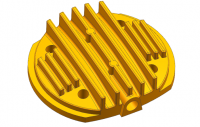

QT400-18AL轮毂铸造工艺的设计 摘要:轮毂作为风力发电系统中的重要部件之一,对其铸件质量要求较高。本文通过对其铸造工艺进行分析从而改进轮毂铸件的品质。

关键词: 轮毂;铸造工艺;炉前控制 目 录

1 QT400-18AL轮毂的工艺设计········································1

1.1 QT400-18AL轮毂材料的选择·······································1

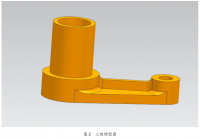

1.2 工艺设计·····················································1

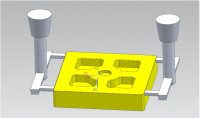

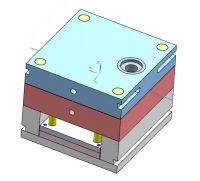

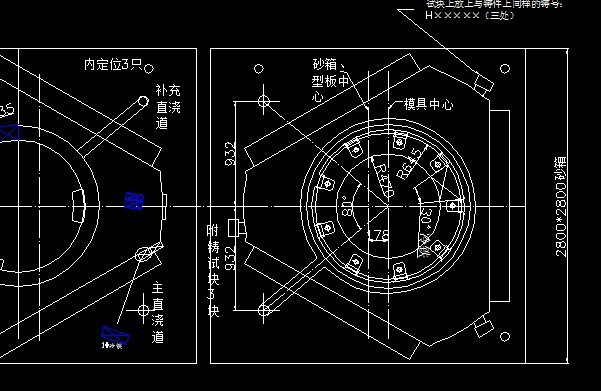

2 QT400-18AL轮毂造型方法的确定····································2

2.1造型方法的选择················································2

2.2型芯的设计···················································3

3 铸造工艺方案的确定···············································3

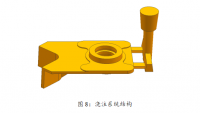

3.1 铸造分型面的选择··············································3

3.2 浇注位置的选择················································4

3.3吃砂量的确定··················································4

4 铸造工艺设计参数的确定············································4

4.1 收缩率·······················································5

4.2机械加工余量··················································5

4.3铸件尺寸公差·················································· 6

4.4起模斜度····················································· 6

4.5最小铸出孔和槽················································ 7

4.6分型负数····················································· 7

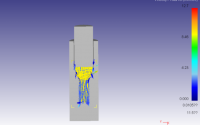

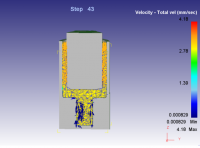

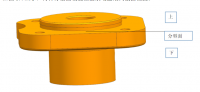

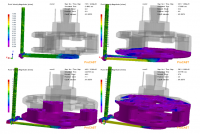

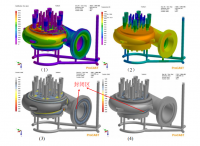

5浇注系统的设置··················································· 7

5.1直浇道······················································· 8

5.2横浇道······················································· 8

5.3内浇道·························································9

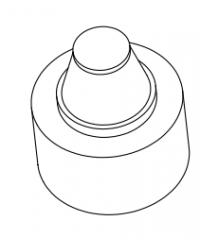

5.4浇口杯·························································9

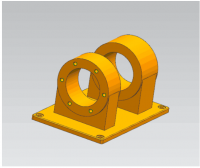

6砂芯设计··························································9

6.1 砂芯设置的原则··················································9

6.2 砂芯的固定和定位················································9

6.3 砂芯的排气·····················································9

7冷铁 ····························································10

8出气孔··························································10

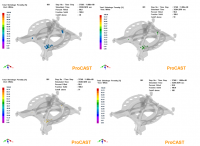

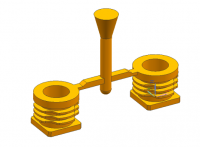

9冒口设计·······················································11

9.1冒口设计原则···············································11

9.2冒口位置的选择原则··········································11

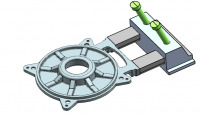

10 QT400-18轮毂的工艺说明··································12

11球化孕育剂的选择和炉前控制··································12

11.1球化剂的选择··············································12

11.2孕育剂选择················································12

11.3炉前控制··················································12

12 开箱时间······················································13

结论·····························································14

参考文献···················································· 参考文献:

⑴劳动人事部培训就业局.铸工生产实习.劳动人事出版社.1984

⑵王文清,李魁盛 . 铸造工艺学. 北京. 机械工业出版社.1998

⑶浙江大学铸工教研组 . 砂型铸造工艺设计 .浙江大学出版社. 1976

⑷李弘英, 赵成志. 铸造工艺设计 . 机械工业出版社. 2006

⑸程能林. 产品造型材料与工艺. 北京理工大学. 1991