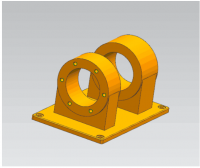

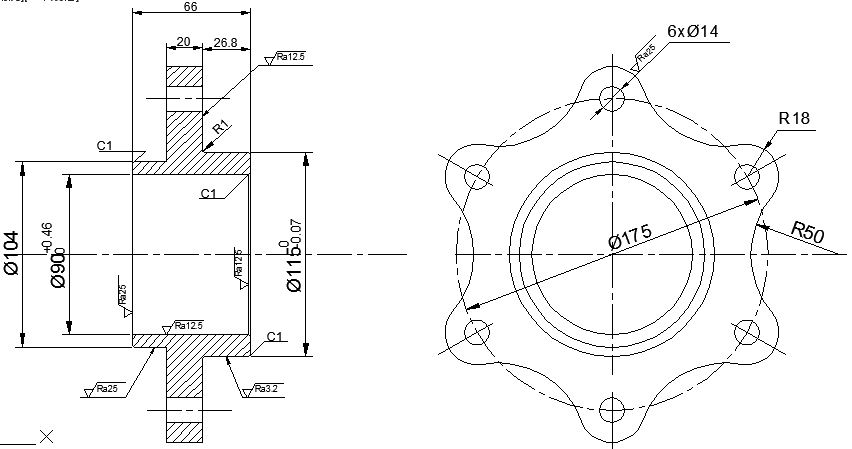

ZG270-500压紧盖铸造工艺及其设计(铸造工艺毕业设计)

摘要

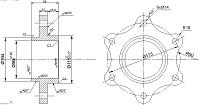

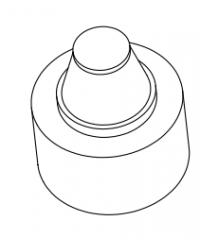

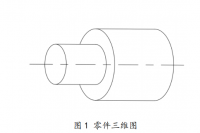

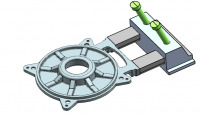

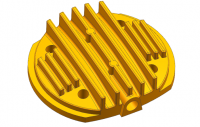

本文根据ZG270—500压紧盖进行铸造工艺设计,通过对该铸件的结构特点、工作条件、技术条件、生产批量的分析,确定其铸造方案。并重点介绍ZG270—500压紧盖的造型(芯)材料的选择,分型面、浇注位置和砂箱的选择,砂芯设计、浇注系统设计以及其他系统的设计。

先从图纸入手,确定其分型面,浇注位置等,再查阅资料,找出相关数据并计算,不仅要保证外观形式正确,还要保证其内部数据正确,使其尺寸、重量、气密性和粗糙度等数据均在允许范围内,并与其他零件配合,无缩孔、气孔和砂眼等缺陷,满足图纸要求的各项指标。同时,为了使其可以批量生产,还要考虑到它的生产成本以及劳动生产率的问题。如果选择的工艺不符合要求,就可能出现铸造缺陷。因此,本文也将介绍铸造过程中可能出现缺陷以及防止的知识,并需要在实际生产中加强控制和避免缺陷出现。

关键词:砂箱设计;热处理工艺;数据;缺陷

ZG270-500 pressure casting process and its design

Abstract

According to ZG270 - 500 cover casting process design, through the analysis of the structure characteristics, casting working conditions, technical conditions, production batch, determine the plan of casting. And focus on the ZG270 - 500 cover model (core) material selection, parting surface, pouring position and sand box selection, design of sand core design, design of gating system and other systems.

First from the drawings of determine the parting surface, pouring position, and access to information, to find the relevant data and calculation, not only to ensure the appearance of the correct form, but also to ensure the internal data correctly, make the data about its size, weight, air tightness and roughness were within the allowable range, and cooperating with other parts, no shrinkage hole and porosity and defects such as sand holes meet drawing requirements of the various indicators. At the same time, in order to make it can be mass production, but also to take into account the cost of production and labor productivity. If the selection process does not meet the requirements, it is possible to cast defects. Therefore, this paper also introduces the process of casting defects and the prevention of knowledge, and the need to strengthen the control and avoidance of defects in the actual production.

Key words: sand box design ; heating treatment process ; data ; defects

目录

一、零件的技术要求和结构分析................................................................3

二、工艺方案分析与确定.............................................................................3

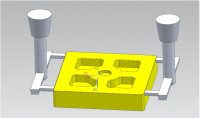

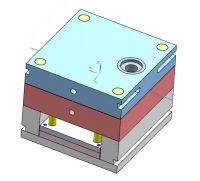

2.1、铸造方法及铸型种类、型砂配方的确定........................................3

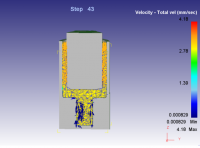

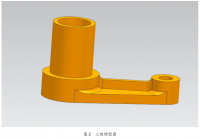

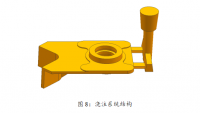

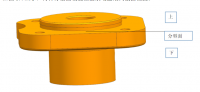

2.2、浇注位置及分型面确定....................................................................4

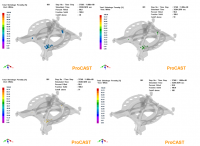

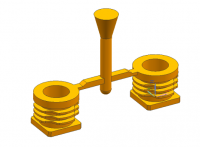

2.3、 砂芯的块数、形状和固定。型芯砂的性能要求及配方..............7

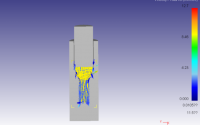

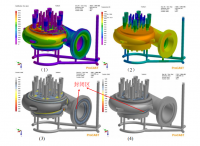

2.4、浇注系统、冒口、出气口、冷铁等的位置和形状.......................8

三、确定工艺数据........................................................................................10

3.1、工艺参数的选择................................................................................9

3.2、芯头结构和具体数据........................................................................10

3.3、初步制订合箱面及确定砂箱尺寸....................................................10

3.4、确定浇冒口系统各部分结构尺寸及出气口尺寸............................12

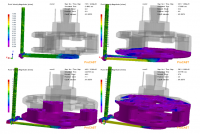

四、预计生产该铸件可能产生的缺陷及防止措施..............................,........17

4.1、飞翅......................................................................................................17

4.2、毛刺......................................................................................................17

4.3、冲砂......................................................................................................18

4.4、气孔、针孔..........................................................................................18

4.5、浇不到..................................................................................................18

4.6、缩孔、缩松、疏松...............................................................................18

五、结论............................................................................................................18

参考文献.............................................................................................................20

参考文献

[1]中国机械工程学会铸造分会.铸造手册:第5卷铸造工艺[M].2版.北京:机械工业出版社,2005.

[2]曹瑜强.铸造工艺及设备[M].2版.北京:机械工业出版社,2008.

[3]李魁盛,马顺龙,王怀林.典型铸件工艺设计实例[M]. 北京:机械工业出版社,2008.

[4]中国铸造协会.铸造技术应用手册:第4卷铸造工艺及造型材料[M].中国电力出版社,2011.