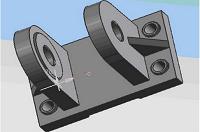

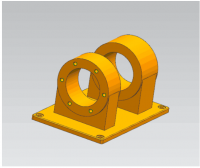

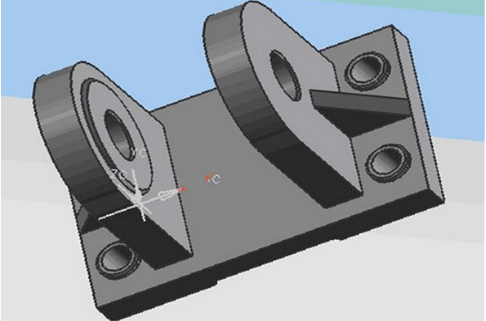

支座砂型铸造工艺设计

摘要:铸造是将液态金属或合金浇铸到与零件尺寸、形状相适应的铸型型腔中,待其冷却凝固后获得毛坯或零件的方法,是机械零件和毛坯成形的主要工艺方法,铸造毛坯因近乎成形,而达到避免机械加工或少量加工的目的降低了成本并在一定程度上减少了时间。铸造通常按其铸型性质不同,可分为砂型铸造、特种铸造和快速成形等方法。

关键词:砂型铸造,铸造,毛坯成型,支座

Summary:casting is will the liquid metal or alloy casting parts size, shape to adapt to the casting cavity, wait for their cooling after concreting get blank or parts method, mechanical parts and blank forming is the main process, casting billet almost forming, and achieved by from mechanical processing or a few processing purpose lowers the cost and to a certain extent, reduce the time. Casting usually according to its casting quality, can be divided into different type of sand casting, special casting and rapid prototyping techniques.

Keyword:Cast, Blank forming, Sand-cast, Bracket

目录

目录.............................................................................................................................................1

第一章 序言...............................................................................................................................3

1.1中国古代铸造技术的发展.................................................................................................3

1.2中国铸造技术发展现状.....................................................................................................3

1.3未来铸造技术的发展.........................................................................................................4

1.4蠕墨铸铁.............................................................................................................................4

第二章 铸造工艺方案的确定...................................................................................................4

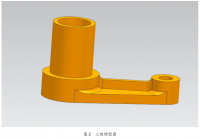

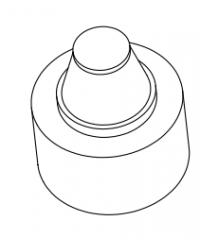

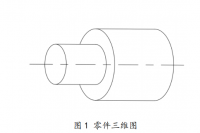

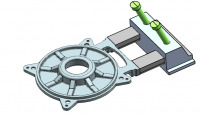

2.1支座的生产条件、及技术要求.........................................................................................4

2.2支座结构的铸造工艺性.....................................................................................................5

2.3造型、造芯方法的选择.....................................................................................................6

2.4浇铸位置的确定.................................................................................................................6

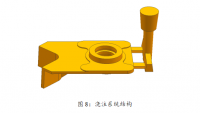

2.5分型面的确定.....................................................................................................................8

2.6砂箱中铸件数量及排列方式确定.....................................................................................10

第三章 铸造工艺参数及砂箱设计...........................................................................................11

3.1 工艺设计参数确定............................................................................................................11

3.1.1 铸件尺寸公差...........................................................................................................11

3.1.2 机械加工余量...........................................................................................................11

3.1.3 铸造收缩率...............................................................................................................12

3.1.4 起模斜度...................................................................................................................12

3.1.5 最小铸出孔和槽.......................................................................................................13

3.1.6 铸件在砂型内的冷却时间.......................................................................................14

3.1.7 铸件重量公差...........................................................................................................14

3.1.8 工艺补正量...............................................................................................................14

3.1.9 分型负数...................................................................................................................14

3.1.10 反型变量.................................................................................................................14

3.1.11 非加工壁厚负余量.................................................................................................15

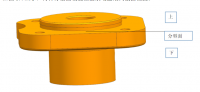

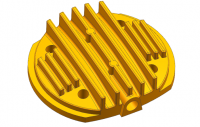

3.2砂芯设计.............................................................................................................................15

3.2.1 芯头的设计...............................................................................................................15

3.2.2 砂芯的定位结构.......................................................................................................15

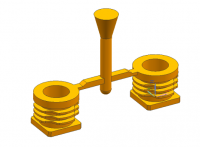

3.2.3 压环、防压环和集砂槽芯头结构...........................................................................16

3.2.4 芯骨设计...................................................................................................................16

3.2.5 砂芯的排气...............................................................................................................16

3.2.6 砂芯的负数...............................................................................................................16

第四章 浇注系统及冒口、冷铁、出气孔等设计...................................................................17

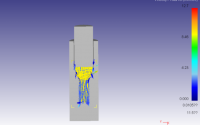

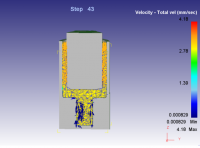

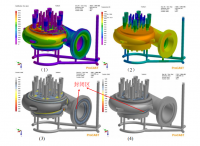

4.1浇注系统的设计.................................................................................................................17

4.1.1选择浇注系统类型....................................................................................................17

4.1.2确定内浇道在铸件上的位置、数目、金属引进方向............................................17

4.1.3决定直浇道的位置和高度........................................................................................17

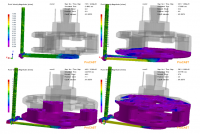

4.1.4计算浇铸时间并核算金属上升速度........................................................................18

4.1.5计算阻流截面积........................................................................................................18

4.1.6确定浇口比................................................................................................................18

4.1.7计算内浇道截面积.....................................................................................................18

4.1.8计算横浇道截面积.....................................................................................................19

4.1.9计算直浇道截面积.....................................................................................................20

4.1.10浇口窝的设计...........................................................................................................21

4.1.11浇口杯的设计...........................................................................................................21

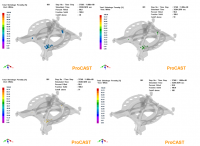

4.2冒口的设计..........................................................................................................................22

4.3冷铁的设计..........................................................................................................................22

4.4出气孔的设计......................................................................................................................22

4.5铸件工艺出品率的校核......................................................................................................23

第五章 铸造工艺装备设计........................................................................................................23

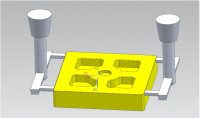

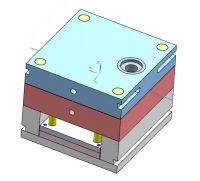

5.1模样的设计..........................................................................................................................23

5.2模板的设计..........................................................................................................................23

5.3芯盒的设计..........................................................................................................................24

5.4砂箱的设计..........................................................................................................................24

第六章 蠕墨铸铁(RUT300)的配料及熔炼计算....................................................................27

6.1蠕墨铸铁(RUT300)的配料计算......................................................................................27

6.2蠕墨铸铁生产控制..............................................................................................................28

第七章 砂型铸造设备选用........................................................................................................28

7.1造型工部设备选用..............................................................................................................28

7.2制芯工部设备选用..............................................................................................................28

7.3溶化工部设备选用..............................................................................................................28

7.4砂处理工部设备选用..........................................................................................................28

7.5清理工部设备选用..............................................................................................................28

参考文献 ....................................................................................................................................28

设计小结......................................................................................................................................30

参考文献

[1] 施延藻.铸造实用手册.沈阳:东北大学出版社,2008.

[2] 李宏英,赵成志.铸造工艺设计.北京:机械工业出版社,2005 .

[3] 王文清,李魁盛.铸造工艺学.北京:机械工业出版社,2002.

[4]陈琦,彭兆弟.铸造合金配料速查手册.北京:机械工业出版社,2009.

[5] 李晨希.铸造工艺及工装设计.北京.化学工业出版社,2014.

[6] 杜西灵,杜磊.铸造技术与应用案例.北京.机械工业出版社,2009.

[7] 胡亚民,冯小明,申荣华.材料成型技术基础.重庆:重庆大学出版社,2004.

[8]陆文华,黄良余,等.铸造合金及其熔炼.北京:机械工业出版社,2002.

[9]张立波, 田世江,等.中国铸造新技术发展趋势.铸造.2005.

http://www.bysj1.com/ http://www.bysj1.com/html/4121.html http://www.bysj1.com/html/2015.html